Scientists from the University of Manchester used microscopic knots to invent a fabric 33,000 times finer than Egyptian linen. have been honoured with a Guinness World Record for weaving threads of individual molecules together to create this ‘world’s finest fabric’. Read more about this invention at SURFACES REPORTER (SR):

Also Read: Fabric created from Metal

In the sheet department, any fabric that counts more than 1,000 is considered as complete luxury and finely-woven. The new fabric even surpassed the most tightly-woven Egyptian linen.

Egyptian woven linen

Egyptian woven linen

Professor David Leigh said: “Weaving molecular strands in this way leads to new and improved properties. The fabric is twice as strong as the unwoven strands and when pulled to breaking point it tears like a sheet rather than clumps of strands detaching. The woven material also acts like a net, allowing small molecules to pass through it while trapping larger molecules in the tiny mesh.”

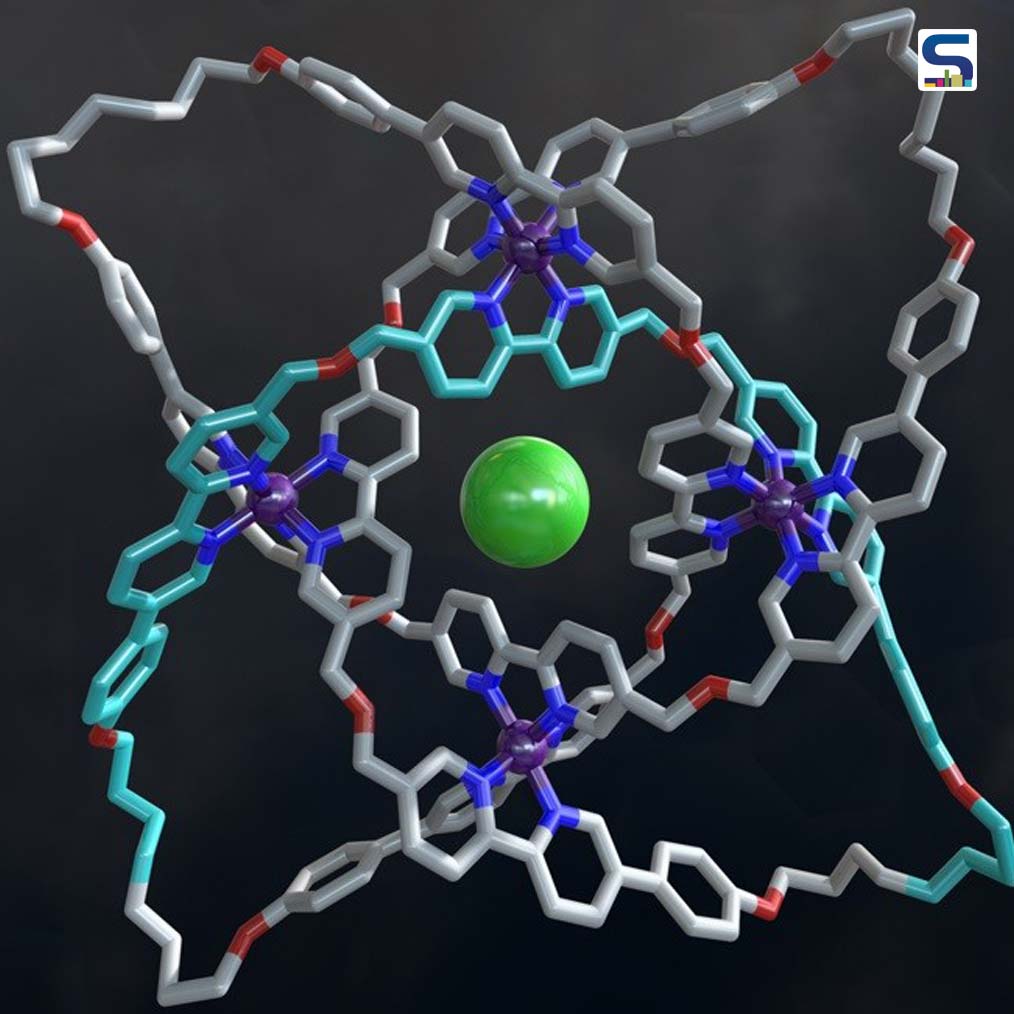

Researchers developed the material from synthetic materials after working out how to fuse the atoms of nitrogen, hydrogen, oxygen, carbon, and Sulphur into knots of molecular strands. The woven building blocks joined together by introducing negatively charged anions and positively charged ions into the mix. to form single sheets of woven molecular strands in fabric just 4 millionth of a millimeter thick (4 nanometres).

“This is the first example of a layered molecularly woven fabric. Weaving molecular strands offers a new way of altering the properties of plastics and other materials.

Also Read: Neri Oxman combines digital fabrication, materials science and synthetic biology to create extraordinary designs

The team also measured the thickness of the molecularly woven fabric using a special instrument called an atomic force microscope, which has a probe tip so sharp that it has a single atom at the end. Each layer of the molecularly woven fabric is just 4 nanometres thick; that’s 10,000 times thinner than a human hair.

Two-dimensional Layers

This is for the first time when scientists developed a way to weave molecular threads in two-dimensional layers. In doing so they have produced a 2D-molecularly-woven fabric that has a thread count of 40-60 million (for comparison, the finest Egyptian linen has a thread count of ~1500 – thread count is the number of strands per inch).

“The number of strands and strand-crossings was measured by shining X-rays on the building blocks. The strands bend the path of the X-rays through the material by a specific amount, enabling researchers to measure how many strands there are per inch. The measurement shows the material has a thread count of 40-60 million strands per inch. In comparison, the finest Egyptian linen has a thread count of around 1500.”

The weaving of threads having diameters ranging from several millimeters (reeds, plant fibres, etc.) to a few microns (wool, cotton, synthetic polymers, etc.) has underpinned progress through the ages, from stone-age humans making nets to catch fish and weave cloth to keep themselves warm to the modern textiles we all use every day.

Immense Possibilities

Although there are limitless possibilities with this innovation yet we will not see things formed by using large sheets of molecularly woven fabrics soon. At the moment, the largest piece of fabric we’ve made is just 1 mm in length. Certainly, it is very small, but still larger than the flakes of graphene when that was first created.

Also Read: 3D forms of Graphene

“This is the first example of a layered molecularly woven fabric. Weaving molecular strands offers a new way of altering the properties of plastics and other materials.”

While it is quite early to say the type of fine materials can be made by using the new invention- Prof Leigh shares a few of its applications

“Molecularly-woven fabrics may be able to clean water, by filtering out bacteria and unwanted ions and molecules. They may be useful for making fabrics that are breathable (allowing through oxygen and water) but blocking toxins or bacteria or viruses,” he said.

“And if we can switch the size and shape of the strand building blocks with light or electricity, we may be able to make the fabrics shrink or expand to fit to order.”

The research was reported in: ‘Self-assembly of a layered two-dimensional molecularly woven fabric’ in the journal Nature.

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

You may also like to read about:

The Fabric Wave by A. J. Architects, Bangalore

Woodskin- Strength of a Wood and Flexibility of a Fabric

and more...