Using a bacterium based technology, researchers from Imperial College of London have been able to create a material that is embedded with sensors to ascertain the damage on the road and successfully repair it. A report by SURFACES REPORTER.

The Technology

According the research paper published in Nature Communication, the researchers using ELMs (engineered living materials) used biology’s ability to heal and replenish material and could respond to damage in harsh environments using a sense-and-response system.

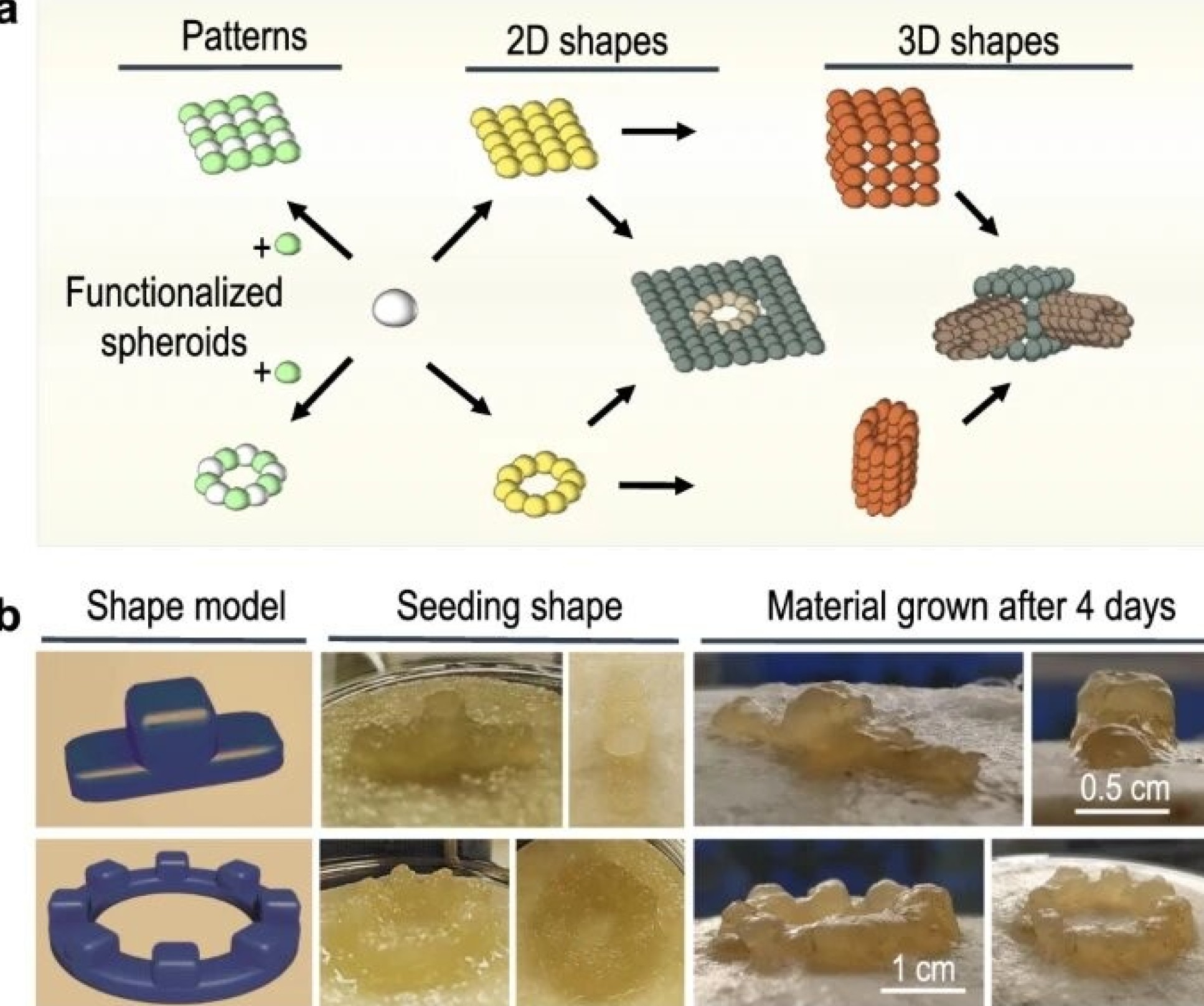

Just like modular pieces are assembled to create varied building structure, using the same principal, bacterial cellulose-based materials can be constructed.

The making of Self Healing Bacteria

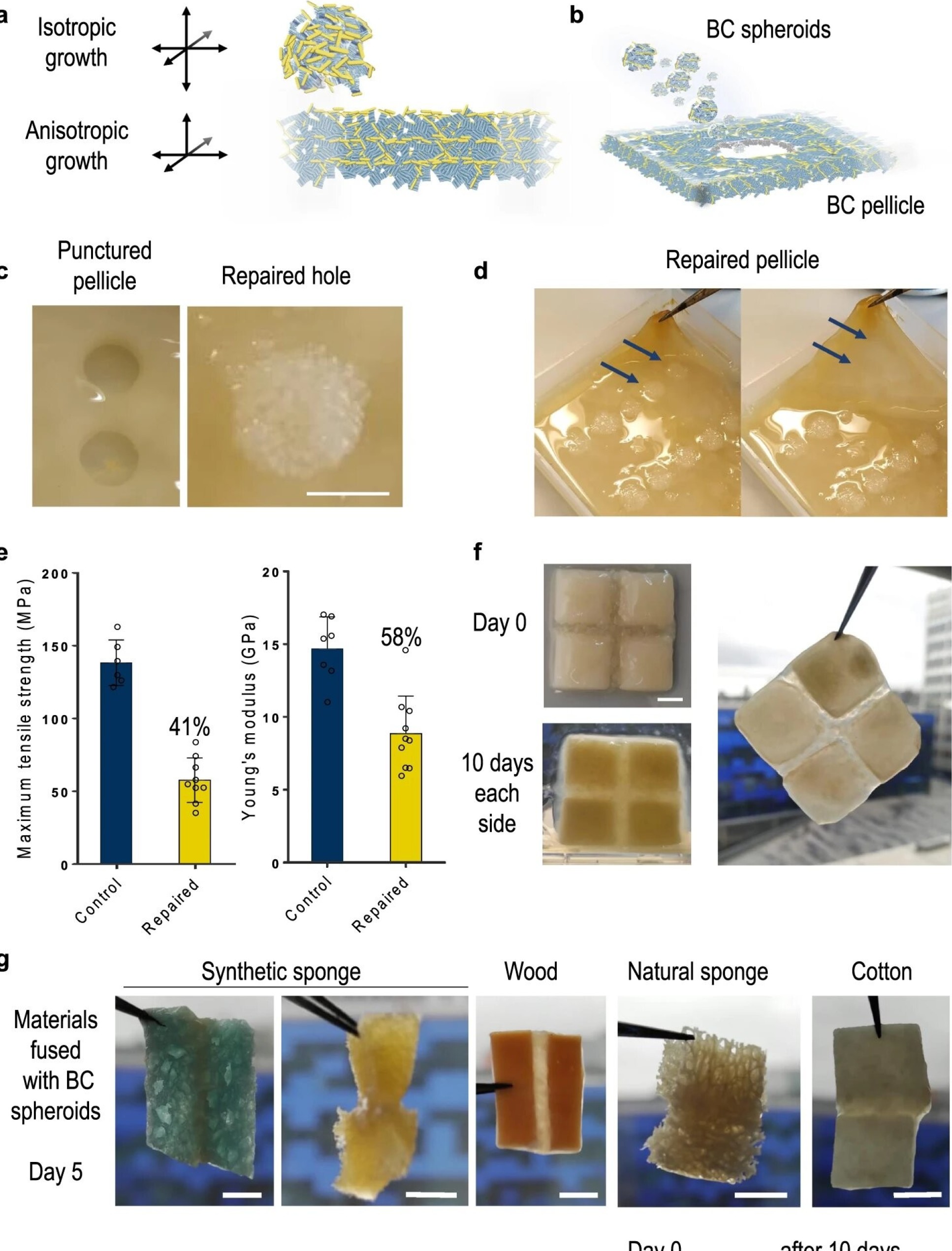

ELMs are created using a genetically engineered bacteria called Komagataeibacter rhaeticus to produce fluorescent 3D sphere-shaped cell cultures, known as spheroids, and to give them sensors which detect damage. They arranged the spheroids into different shapes and patterns, demonstrating the potential of spheroids as modular building blocks.

The researchers then used a hole punch to damage a thick layer of bacterial cellulose - the scaffold-like material made by some bacteria on which ELMs are produced. They then inserted the freshly grown spheroids into the holes and, after incubating them for three days, saw excellent repair that was structurally stable and restored the consistency and appearance of the material.

Lead author Professor Tom Ellis of the Department of Bioengineering at Imperial said: “By placing the spheroids into the damaged area and incubating the cultures, the blocks were able to both sense the damage and regrow the material to repair it.”

First author Dr Joaquin Caro-Astorga of Imperial’s Department of Bioengineering said: “Our discovery opens a new approach where grown materials can be used as modules with different functions like in construction. We are currently working on hosting other living organisms within the spheroids that can live together with the cellulose-producing bacteria.

"The possible living materials that can come from this are diverse: for example, with yeast cells that secrete medically-relevant proteins, we could generate wound-healing films where hormones and enzymes are produced by a bandage to improve skin repair.”

Researchers saw excellent repair that was structurally stable and restored the consistency and appearance of the material.

Researchers saw excellent repair that was structurally stable and restored the consistency and appearance of the material.

The growth in popularity of bacterial cellulose for its outstanding properties is the response to the worldwide challenge to find new materials with better-tailored functional behaviours.

Dr Patrick Rose, science director of US Office of Naval Research Global London, which part-funded the research, said: “The challenge is to mimic and combine the distinct features biology has to offer. We are not only trying to emulate those systems, but engineer biology to have additional features that are more amenable to the needs we seek without direct intervention. Ultimately, we want to increase the lifetime of a product, prevent failures of systems before the problem is visible to the naked eye and have the material think for itself.”

The next step for this group of researchers is to develop new spheroid building blocks with different properties, such as combining them with materials like cotton, graphite and gelatins to create more complex designs. This could lead to new applications like biological filters, implantable electronics or medical biosensor patches.

Patterns and 3D shapes made from the spheroids

Patterns and 3D shapes made from the spheroids

SURFACES REPORTER View

The research, though in its nascent stage, can prove to be a big leap particularly in a country like India where potholes and roadcracks are the worst nightmare for a driver. Every year, crores of rupees are spent for the maintenance of roads and highways but with every rains, the situation of every state roads get bad to worst. In addition, many people lose their lives in road accidents every year. Such technology, if viable in terms of cost, will come like a boon for the roads infrastructure and save a lot of expenditure in the time to come.

Source: Imperial College London

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

6 Easy Tips to Maintain Your Particle Boards | SR Application Ache

Bamboo in Construction: The Rise in Organic Architecture | SR Material Specials

PFAS polluted soil to turn into bricks | Claybens | Netherlands | SURFACES REPORTER Material update

Solid Surfaces: Things you must know | Surfaces Reporter Material Overview

And more…