British materials startup Carbon Cell recently unveiled a carbon-negative, fully compostable alternative to polystyrene that could significantly reshape the packaging and construction industries. Using agricultural waste as its primary ingredient, the company has created a lightweight rigid foam that mimics the performance of conventional expanded polystyrene (EPS) while eliminating the pollution and fossil-fuel dependence associated with plastic-based foams. Know more about it on SURFACES REPORTER (SR).

Once the product is discarded, the natural polymer binder decomposes under standard home composting conditions, leaving behind only the biochar.

Compostable, plastic-free foam

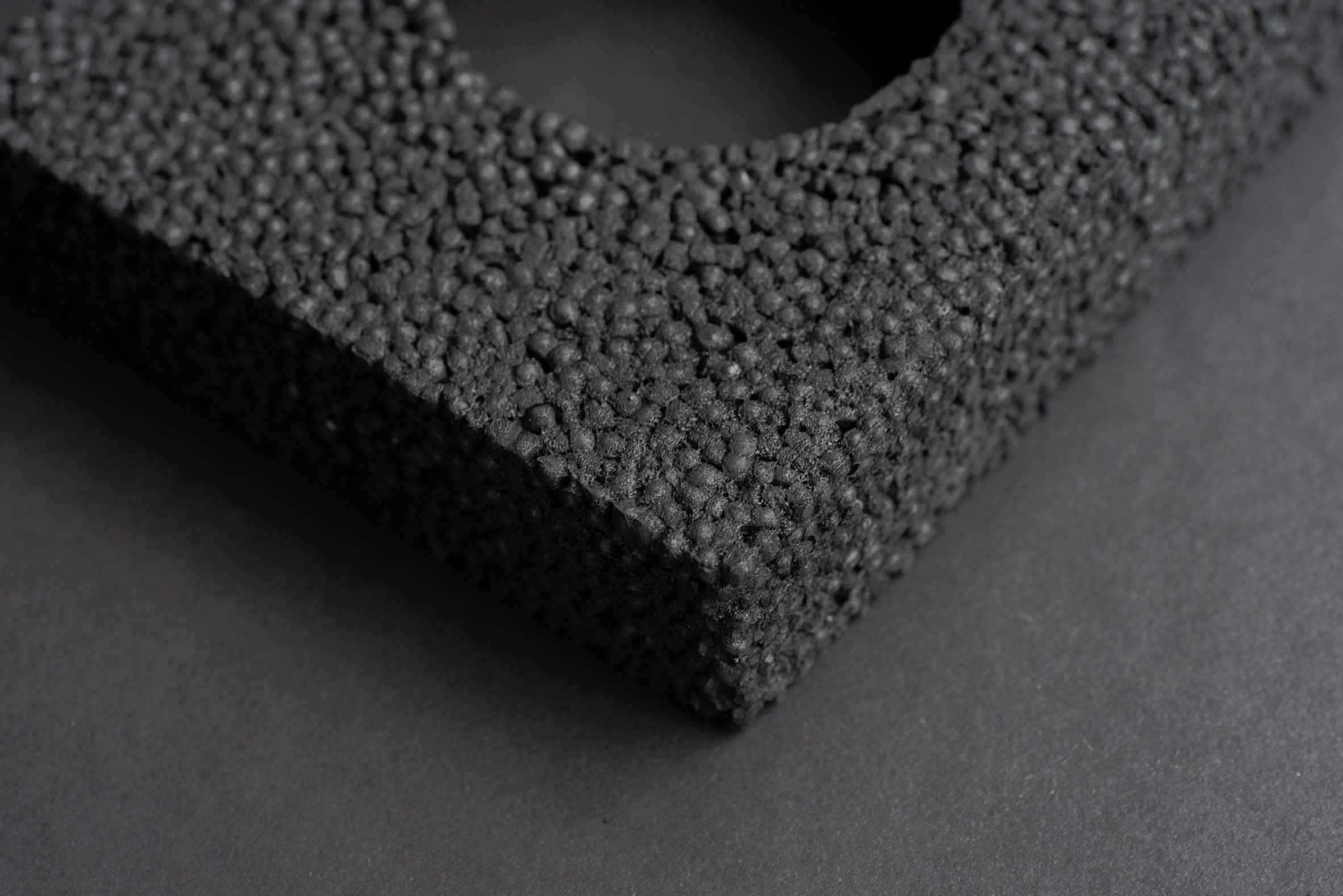

Carbon Cell is reportedly nearing its commercial production and has already attracted global attention for its environmental potential. While it visually resembles polystyrene, featuring the same cellular, bead-like texture, it stands out with its distinctive deep black colour. This shade comes from its core ingredient biochar, the carbon-rich residue left after biomass such as crop waste undergoes pyrolysis. Unlike petroleum-derived polymers, biochar is renewable, naturally occurring and capable of storing atmospheric carbon long after the product’s useful life is over.

According to the company, every kg of the foam removes around 2kg of carbon from the atmosphere, making it not just non polluting but actively regenerative. The material has been developed by a multi-disciplinary team consisting of scientist Elizabeth Lee, engineer Eden Harrison and designer Ori Blich. The trio met while studying at the Imperial College London and the Royal College of Art, where they began exploring the promising qualities of biochar. They were particularly interested in its lightness, insulation capacity, porosity and natural moisture buffering, all the qualities that closely mirror the properties of expanded polystyrene.

According to the company, every kg of the foam removes around 2kg of carbon from the atmosphere, making it not just non polluting but actively regenerative.

The process

To create a foam that could directly compete with existing plastic products, the team adapted the standard EPS manufacturing process. They began by combining biochar with bio-based polymers to form small, dense pellets. These pellets were then heated, causing them to expand like popcorn into a rigid foam exhibiting the same structural qualities as polystyrene. One of the advantages of this approach is that existing polystyrene expansion equipment can be repurposed, allowing manufacturers to adopt the material without major infrastructural changes. The foam can also be moulded into complex shapes just like EPS, making it suitable for a wide range of applications.

What sets Carbon Cell apart is its end of life behaviour. Once the product is discarded, the natural polymer binder decomposes under standard home composting conditions, leaving behind only the biochar. This remnant continues to lock carbon away for generations and simultaneously improves soil fertility. Instead of contributing to plastic pollution, the material enhances ecological health after its use phase.

Reportedly, the company plans to begin production in December, supplying materials for its first pilot projects while preparing to scale. This rapid expansion is crucial because EPS remains widely used despite its environmental drawbacks and extremely low recycling rates. Global production of expanded polystyrene is reportedly estimated to be between 7-12.8 million tonnes annually, and the numbers continue to rise. Although bans have been implemented in certain packaging sectors, EPS still dominates fields such as protective packaging for appliances, electronics, furniture, and most importantly, the building industry.

As per the team, the construction sector represents Carbon Cell’s largest future market, especially for building insulation. However, certification and scale requirements mean that widespread adoption will take time. Meanwhile, the team is developing product variations for other industries, including acoustic panels, interior design components, thermal packaging, automotive composites, and even props for film, television and theatre, where foam usage is substantial.

Image credit: Carbon Cell