Reconfigurable glass masonry promises a sustainable future for architecture by enabling buildings to be assembled, disassembled, and rebuilt in endless cycles reports SURFACES REPORTER (SR)

What if construction materials could be put together and taken apart as easily as Lego bricks? Imagine reconfigurable masonry that can be disassembled at the end of a building’s life and reassembled into a new structure - a sustainable cycle where the same physical building blocks could serve generations of architecture.

This concept lies at the heart of circular construction, an approach that reuses and repurposes building materials to minimize the manufacturing of new ones and cut down the industry’s embodied carbon -the greenhouse gas emissions tied to every stage of construction, from material production to demolition.

Now, engineers at MIT are pushing this vision closer to reality with a groundbreaking material innovation: 3D-printed, interlocking glass bricks. Developed with a custom glass-printing technology from MIT spinoff Evenline, these multilayered glass bricks are shaped like a figure eight and designed to interlock seamlessly, much like Lego.

Glass: From Fragile to Future-Proof

In mechanical tests, a single glass brick demonstrated strength on par with conventional concrete blocks. To showcase their potential, the researchers constructed a wall using the interlocking bricks, proving that glass masonry can be both structural and recyclable.

“Glass is a highly recyclable material,” explains Kaitlyn Becker, assistant professor of mechanical engineering at MIT. “We’re taking glass and turning it into masonry that can be disassembled and reassembled into new structures -or remelted and reprinted into entirely different shapes. This builds into our idea of a sustainable, circular building material.”

For Michael Stern, founder of Evenline and former MIT researcher, the material represents a shift in thinking: “Glass as a structural material kind of breaks people’s brains. We’re showing that this is an opportunity to push the limits of what’s been done in architecture.”

A glass brick being printed with custom 3D glass printing technology | Photo Credit: Ethan Townsend

Printing the Future of Architecture

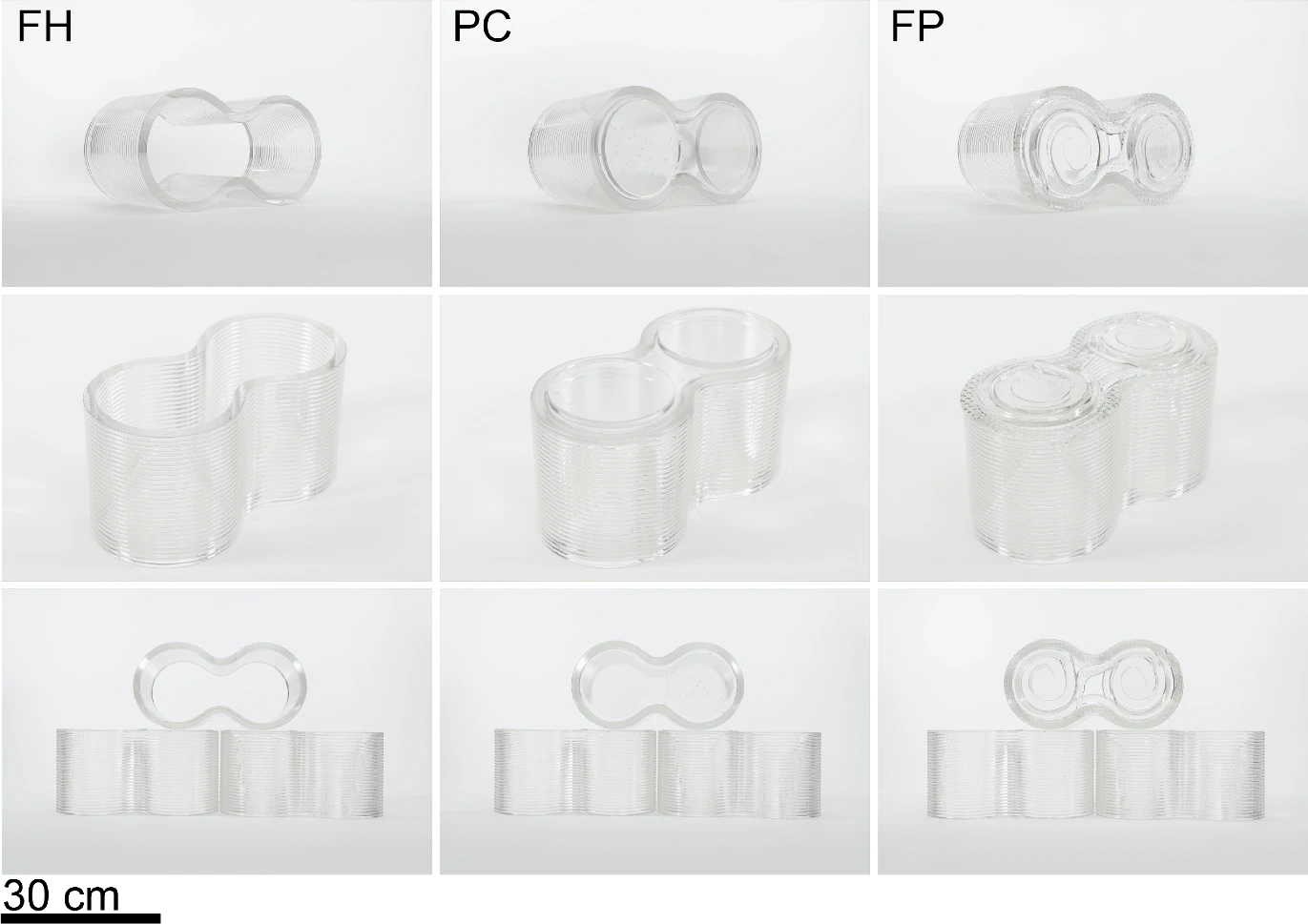

The team used the Glass 3D Printer 3 (G3DP3), which melts crushed glass bottles into printable form. Each brick was produced with two round pegs -similar to Lego studs -allowing the bricks to interlock. A removable layer between bricks prevents scratches or cracks and can be taken out if the structure is dismantled, enabling bricks to be recycled infinitely.

Interestingly, the figure-eight shape of the blocks not only enhances stability but also allows for curved walls and more fluid architectural forms.

Stronger Than It Looks

To test structural integrity, the glass bricks were subjected to industrial hydraulic presses. The strongest versions withstood pressures comparable to concrete masonry, especially when combined with separately manufactured interlocking elements. The team envisions refining these features so more of the structure can be 3D-printed in pure glass.

With these results, the researchers successfully demonstrated a curved glass-brick wall and now plan to scale up to larger self-supporting structures -from temporary pavilions to potentially permanent facades and interior walls.

Each manufacturing method is shown from left to right: FH (Fully Hollow), PC (Print-Cast), and FP (Fully Printed) | Photo Credit: Ethan Townsend

Toward Circular Architecture

This innovation marks a step toward buildings that are modular, reconfigurable, and endlessly recyclable. Instead of demolition waste, tomorrow’s structures could supply their own future materials, dramatically reducing carbon emissions and construction’s environmental footprint.

As Stern concludes: “We’re thinking of stepping stones to buildings. A pavilion today could be reconfigured tomorrow into something else. These blocks could go through many lives.”