Industrial design students Charlotte Böhning and Mary Lempres of Doppelgänger have developed a new material, named Chitofoam- a bioplastic version of polystyrene foam which is made from the exoskeleton of mealworms living in their homemade biodigester. Owing to its lightweight, shock-absorbent, and water-resistant properties, the material is suitable for food packaging, as it can be moulded into packing peanuts, cups and other shapes. Read more about this material below at SURFACES REPORTER (SR):

Also Read: Chinese floor and wall tiles to get costlier in India | SR Material news update

The material can be developed from any kind of mealworms such as lobsters, beetles, or larval form of the mealworm beetle. According to Lempres and Böhning, growing edible mealworms are low-resource, affordable, and space-efficient. They further say that the food in mealworm packaging is double as protein efficient as beef.

The material can be developed from any kind of mealworms such as lobsters, beetles, or larval form of the mealworm beetle. According to Lempres and Böhning, growing edible mealworms are low-resource, affordable, and space-efficient. They further say that the food in mealworm packaging is double as protein efficient as beef.

What is Chitofoam System?

It is a type of circular system that takes the exoskeletons of Styrofoam (expanded polystyrene)-eating mealworms and converts them into a new, biodegradable, shock-absorbent bio-foam for packaging of eatables.

Styrofoam is non-biodegradable material and just cracks into tinier pieces called 'Microplastics'.

Styrofoam is non-biodegradable material and just cracks into tinier pieces called 'Microplastics'.

Chitofoam: A Compostable Alternative

As per the researchers, the world produces over 14 million US tons of polystyrene (plastic foam) each year. India alone throws away 9.46 million tonnes of plastic waste every year while the Americans generate around 25 billion Styrofoam cups waste per year. Moreover, these cups require almost equal to half millennia to degrade. In addition, regular EPS is difficult and too costly to recycle, resulting in causing almost 30 percent of landfill waste.

The new bioplastic material is a compostable substitute to traditional expanded polystyrene (EPS).

The new bioplastic material is a compostable substitute to traditional expanded polystyrene (EPS).

Also Read: New Concrete Testing squad for convenient on-site fresh concrete test | SURFACES REPORTER Material news

How Chitofoam is Formed?

While polystyrene is petroleum-based styrene, which is as per WHO has considered a "probable carcinogen," Chitofoam is derived from a biopolymer also known as Chitin, which mealworms use to build their strong yet flexible exoskeleton."

"In our studio, we began to dispose of our modelling foam and packaging waste in a homemade mealworm bio-digester for depolymerization. As material developers and designers, we began to collect the exoskeletons that our plastic-eating worms shed and extracted a biopolymer gel called chitosan," explain the designers.

"In our studio, we began to dispose of our modelling foam and packaging waste in a homemade mealworm bio-digester for depolymerization. As material developers and designers, we began to collect the exoskeletons that our plastic-eating worms shed and extracted a biopolymer gel called chitosan," explain the designers.

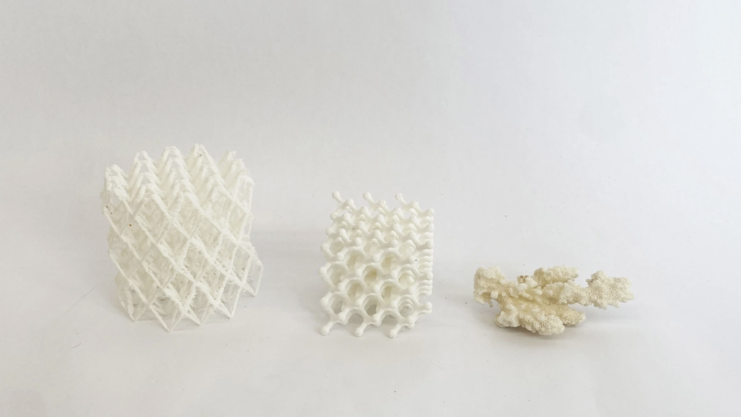

‘After much development, we created a lightweight, water-resistant, shock-absorbing, and backyard-compostable packaging material analogous to styrofoam. We are in the process of pushing our replacement ‘Chitofoam’ further by reimagining packaging and designing more efficient, lattice-structured forms for preserving and protecting products."

‘After much development, we created a lightweight, water-resistant, shock-absorbing, and backyard-compostable packaging material analogous to styrofoam. We are in the process of pushing our replacement ‘Chitofoam’ further by reimagining packaging and designing more efficient, lattice-structured forms for preserving and protecting products."

Certainly, Chitofoam is an innovative material that is expected to provide solutions to the future global issues of improper waste management/food shortage/uncertainty, the accumulation of microplastics within our ecosystems. An interesting fact about Styrofoam-eating mealworms is 100 percent suitable for human consumption. Further, mealworm farming has also been deemed to be an ecologically sustainable solution to malnutrition, particularly in developing rural economies.

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

MIT Chemical Engineers Create Plastic-like Material Stronger than Steel

Chalmers Researchers Revolutionise MOF to Harvest Water from Desert Air | Material Update

And more…