A unique exploration connecting computational design and the use of leftover materials within the forestry industry led to the birth of regrowth. The project by Simon Gehrung for his Industrial Design Course studies the evolved geometries that take advantage of their formal and constructive properties.

Possibilities of leftover wood

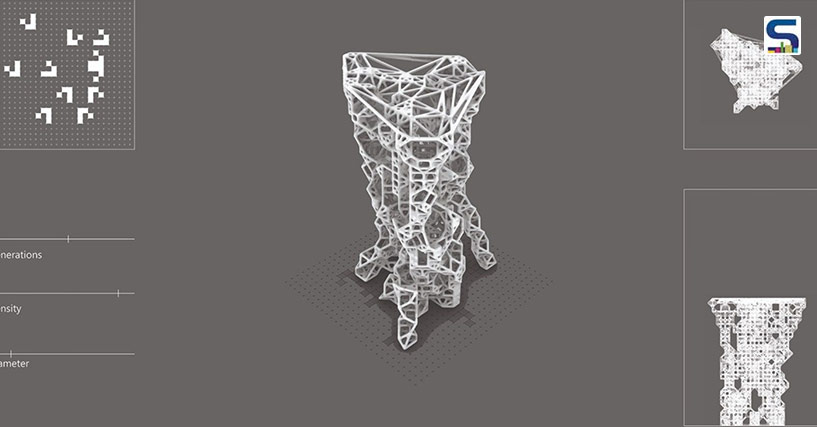

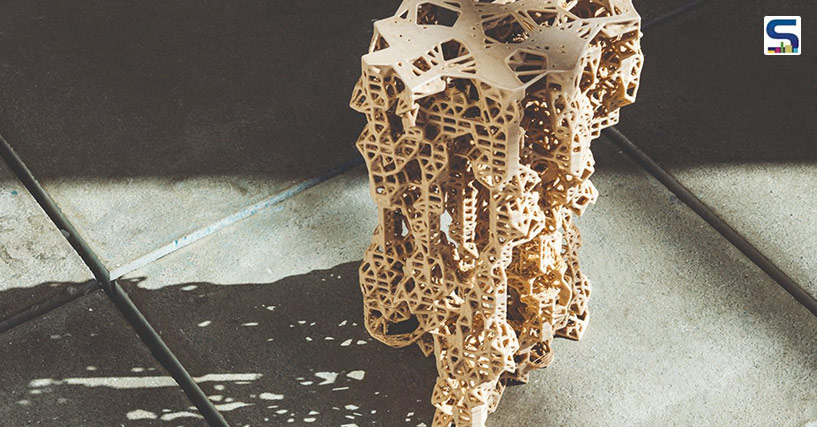

Wood is a naturally grown material that is often seen as a linear and standardized unit. However, the naturally grown form language of wood is not elaborately imitated but consistently and sustainably taken from nature. regrowth focuses on embodying the growth story of its material and its dynamic process. This dynamic system is created through the use of digital fabrication methods and algorithmic tools that respond to the constantly changing demands of the material.

According to Simon, two approaches emerge from this system where each represents an extreme in the treatment of waste wood. While one uses the whole branches (read largest possible parts) with complex shapes, the other is the regeneration of fine particle-sawdust (read smallest particles). These two approaches address the loss of valuable raw materials. regrowth shows the possibilities of how existing potentials of leftover wood resources can be used to develop new design qualities in furniture design.

Celebrating naturally grown shapes

As for the table, the design and construction of the furniture are adapted to the naturally grown geometries of branches. regrowth highlights that instead of crushing the branches, they can be processed minimally using digital tools and manufacturing methods, thereby also celebrating their naturally grown shape. The stool, on the other hand, highlights the loss that every wood processing entails, right from it being chipped to being turned into fine particles (sawdust). The material tends to lose its constructive and formal properties due to machining. Inspired by the specific cell growth of the tree, the material that gets broken down into its individual parts is rearranged again.

regrowth aims to showcase how computational tools and digital manufacturing methods can be sensitively used for the strategic use of residual materials. Simon informs that the strengths of digital, computer-aided tools, which are often used for the production of repetitive parts from standardized materials, should be used in this process to address the different geometries of the naturally grown material.

Image credits: Green Product Awards