Cofounders Jonas Pettersson, John Lofgren and Petrus Palmer of Form Us With Love (FUWL) have recently collaborated with entrepreneurs Johan Ronnestam and Fredrik Franzon to create acoustic panels made out of textile waste. The Stockholm-based design studio has always ventured into exploring and establishing new sustainable ways by taking conventional architectural products and making them more visually appealing. One instance is where the FUWL team used thermal acoustic insulation properties of a Swedish-made building material Traulit, which was first invented in 1940, and reinvented its aesthetics. However, the team recently introduced the BAUX Acoustic Flexfelt System which is fully compostable at the end of its life. Find out more about their work on SURFACES REPORTER (SR).

The three partners had met at an industrial design school in Sweden. It was during the graduation year that the three discussed the potential of establishing a studio. And the rest is history. The trio went on to work on wood wool building material which later turned into a global interior solution. They further went on to launch a unique paper pulp solution that was made out of 100 per cent natural ingredients and was also compostable at the end.

The unique design studio has now invested in taking the post-production of textile offcuts to another level by giving them a second life as a commercial acoustic solution. Named BAUX, the product will be not only sustainable in nature but will also support the challenges of architecture.

Knowing mankind’s urge on depending on finite virgin materials with no regard for carbon emission, FUWL decided to tap the Swedish textile industry to transform textile waste which is destined for landfills into an upcycled innovation. For this, FUWL collaborated with The Loop Factory and textile producer Ludvig Svensson. Thereon, the team commenced the design process of turning textile offcuts into acoustics. The main reason behind this was to save the existing resources by using manufactured materials and reusing them to create a new product.

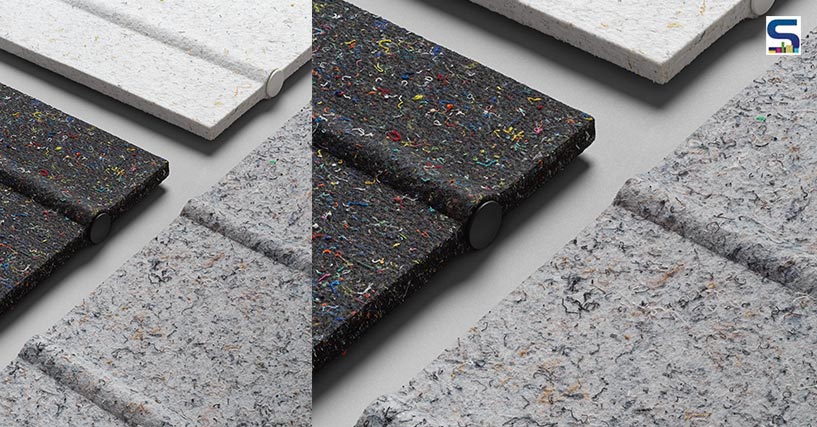

BAUX Acoustic Flexfelt is made out of a mono-material blend that can be taken back and reproduced. The acoustic material is thus created by combining 100 per cent polyester-based threads with energy-efficient polyester fibre. Additionally, no waste is generated during the manufacturing process.

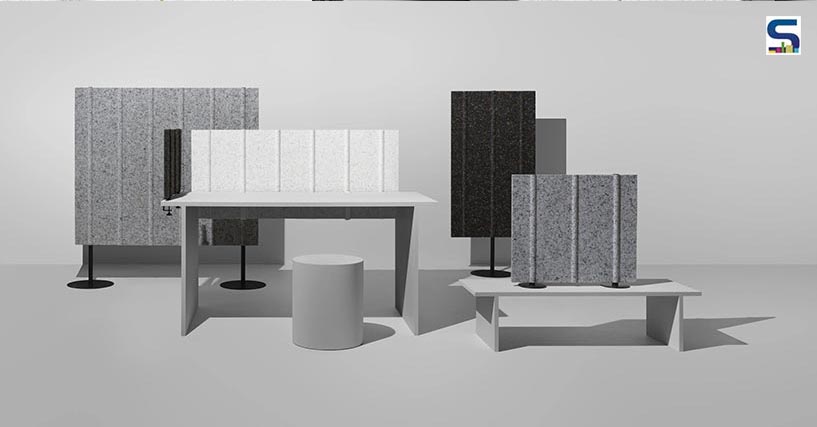

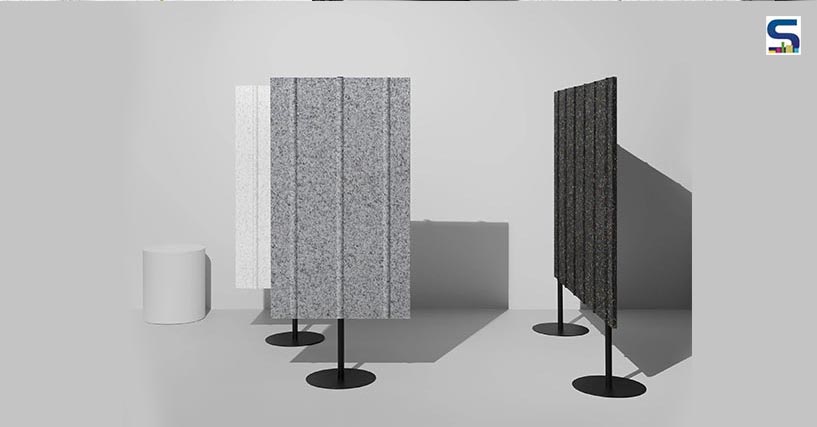

Designed to enhance acoustics, BAUX Acoustic Flexfelt System is ideal for making partitions within workspaces without the need for heavy construction work. They can be used to form a clamped desk divider as well as a free-standing partition. The felt system’s upcycled fibers do the needful job without compromising its performance.

Available in an array of industrial offcuts, from lighter shades to dark ones, BAUX Acoustic Flexfelt System comes with a subtle blend of colourful threads which are the natural result of the repurposing waste fibre.

Image credits: BAUX and Form Us With Love