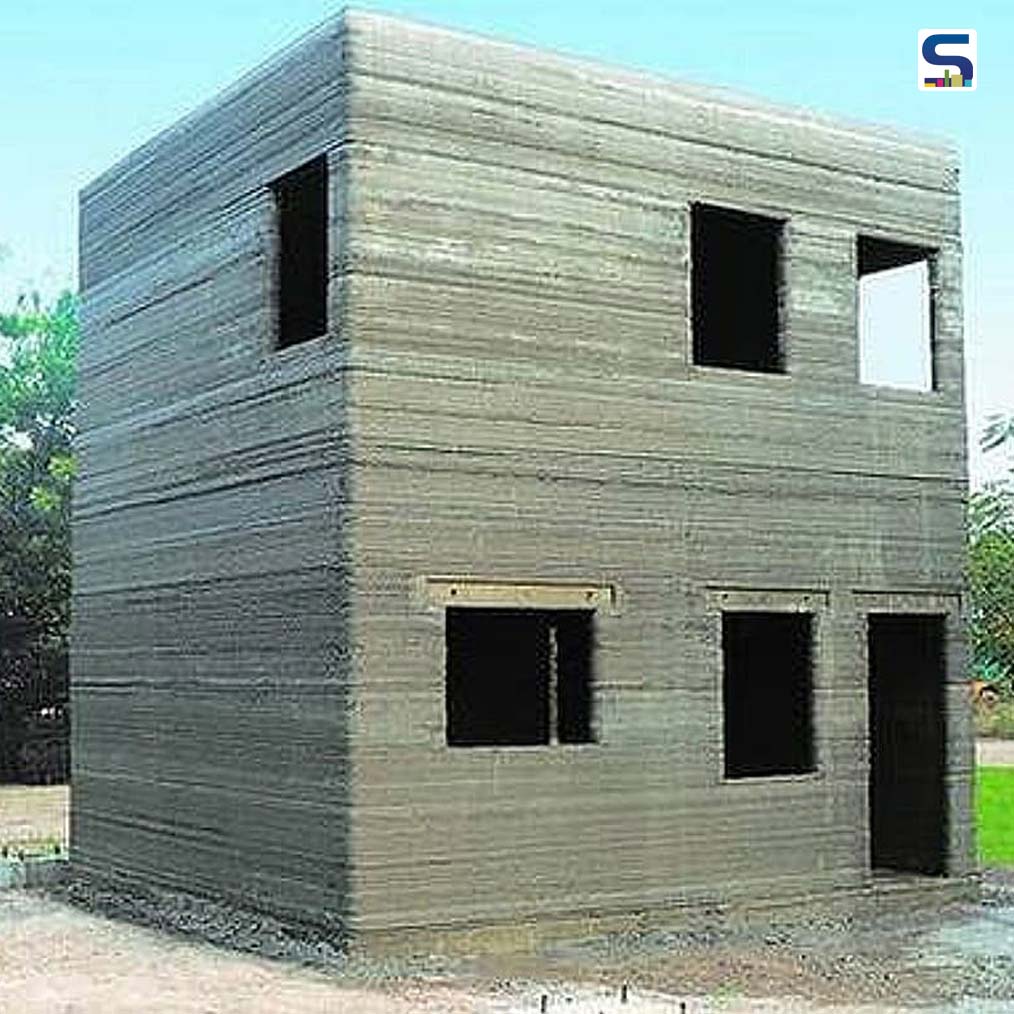

L&T Construction, a wholly-owned subsidiary of the Larsen & Toubro conglomerate, has completed the construction of a two-story 3D-Printed building, which is the very first of its kind in India. The firm used locally available materials for constructing this 700 sq feet multi-floor building. 3D-printed technology has always been a huge impact on several other industries such as healthcare where 3D printing has assisted and is still helping in the research on human tissues and developing treatment techniques which went unnoticed earlier. But, will 3D printing be acceptable for the building sector where quality and sturdiness are prerequisites? Check out at SURFACES REPORTER (SR)’s this post to know what L&T claimed about this 3D building:

Also Read: World’s First 3D Printer That Uses Paper Pulp Instead Of Plastic

MV Satish, senior executive vice-president at L&T Construction, claims that not only will 3D printing accelerate the manufacturing of multi-floor constructions, but actually improve the quality and durability of houses. The base material of the building, used as input material for the 3D printer, is described by the company as “a special, in-house developed concrete mix using indigenously available regular construction materials.

How this 3D Building was formed?

The building is 3D printed by using a fully automated 3D printer at L&T’s Kanchipuram facility with a distinctive, in-house developed concrete mix.

According to the firm, ‘except for the horizontal slab members, the entire building structure was 3D printed 'Cast in Situ' at the job site in an 'open to sky' environment within 106 printing hours.’

The company printed the building with both vertical reinforcement bar and horizontal distributors using a welded mesh that satisfies provisions in the Indian Codes and adjusts the cost of construction.

The building has ground plus first floor with reinforcement, which proves the potential of 3D printing technology in a multi-floor building.

The company also claims that the construction by using this technology will be a catalyst for affordable housing- in terms of quality, cost, and speed of construction.

Earlier in November 2019, the company had 3D printed a 240 sq. feet, 1 BHK apartment, which was in line with the usual Economical Weaker Section (EWS) building layout. The design was done to explore the possibility of this advanced technology.

The construction by using 3D printing technology will surely help to get faster construction in less time as 3d printers can work efficiently for long hours. This achievement will also aid to the Indian government’s ‘Housing for All’ scheme for 2022- in which it seeks to construct almost 60 million houses for the needy.

The adoption rate of 3D printing or additive manufacturing has increased over time in the architecture field. With advanced 3D printers are coming into the market every year, there is no doubt that the 3D printing industry will soon become part of the wider manufacturing ecosystem. To help you better understand where the 3D printing industry is headed, we have compiled all information about its history, benefits, challenges, major advancements, and what the future holds for this exciting technology.

Don’t miss to read this article to stay updated with this rapidly evolving 3D Printing industry: Is 3D Printing the Future of Manufacturing Ecosystem?

What's your view about this 3D printed building? Let us know in the comment section below.

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

3D Printed “Arabesque Wall” with 200 Million Individual Surfaces

3D Printed Face Shields to Help Medicos Fight COVID-19