Developer of advanced construction technologies including robotics, software and building materials ICON along with BIG-Bjarke Ingels Group and NASA recently announced a 3D printed habitat named Mars Dune Alpha, which is touted to help in long-duration exploration missions. As a part of NASA’s Crew Health and Performance Exploration Analog (CHAPEA) programme, Mars Dune Alpha’s analog mission will not only provide insights for NASA’s space food system but also physical and behavioral health and performance outcomes for future space missions and will be home to the crew for which NASA is currently actively seeking. Going forward, the investigative nature of the project will also help in understanding humanity’s first home on another planet and will potentially lay the foundation for a new Martian vernacular.

Top: Mars Dune Alpha is touted to help in long-duration exploration missions; Above: The project will also help in understanding humanity’s first home on another planet and will potentially lay the foundation for a new Martian vernacular.

Top: Mars Dune Alpha is touted to help in long-duration exploration missions; Above: The project will also help in understanding humanity’s first home on another planet and will potentially lay the foundation for a new Martian vernacular.

Need for technology

Located at the Johnson Space Centre, Houston, the 1,700-sq ft structure will be 3D printed by ICON’s next-gen Vulcan construction system. Research from the Mars Dune Alpha habitat’s CHAPEA data – a sequence of three one-year Mars surface mission simulations at the centre – will be used by the American space agency to inform risk and resource trades that will support the crew’s health and performance while their time on Mars. Experimental in nature, part of the project aims at determining the potential of 3D printed space exploration habitats alongside additive construction technology. The experimental design created out of the amalgamation of these two ideas may eliminate the need to launch larger quantities of building materials on multiple flights on the extraterrestrial land, thereby curbing the cost.

The 1,700-sq ft structure will be 3D printed by ICON’s next-gen Vulcan construction system.

The 1,700-sq ft structure will be 3D printed by ICON’s next-gen Vulcan construction system.

According to Jason Ballard, co-founder and CEO, ICON, the Mars Dune Alpha is the highest fidelity simulated habitat ever constructed by humans. He further tells Surfaces Reporter, “Mars Dune Alpha is intended to serve a very specific purpose – to prepare humans to live on another planet. We wanted to develop the most faithful analog possible to aid in humanity’s dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction scale 3D printing is an essential part of humanity’s toolkit on Earth and to go to the moon and Mars to stay.”

Part of the project aims at determining the potential of 3D printed space exploration habitats alongside additive construction technology

Part of the project aims at determining the potential of 3D printed space exploration habitats alongside additive construction technology

Life on the Red Planet

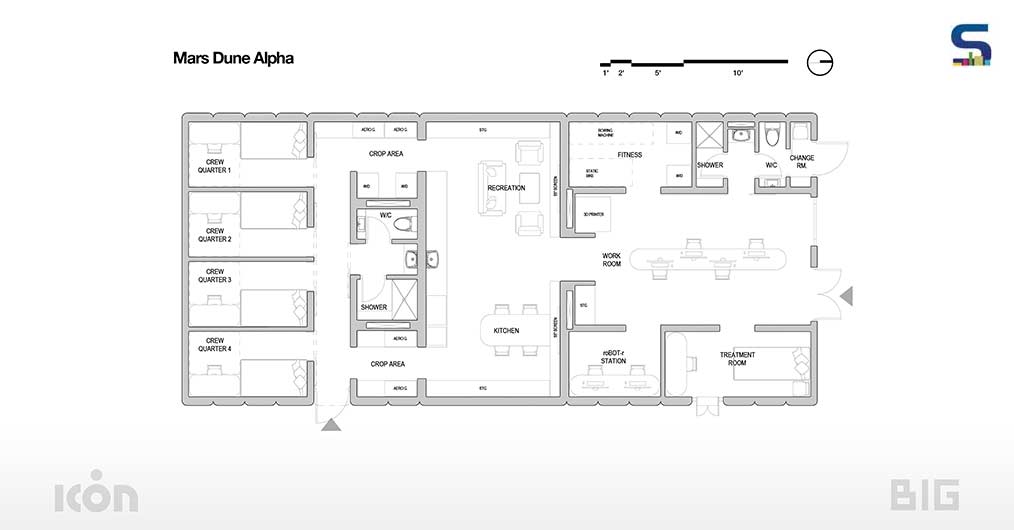

Humans have been trying to explore Mars for a long time. Mars Dune Alpha will be turning this dream of many into a reality soon. Life in Mars Dune Alpha will give its occupants an expected experience of living on the Red Planet. Keeping in mind the gradient of privacy, BIG is designing the layout of the innovative structure. One end of the habitat will be housing four private crew quarters alongside the other end which will comprise dedicated workstations, medical stations and food-growing stations. A shared living area will bifurcate these two ends. To break the monotony of spatial living and crewmember’s fatigue, varying ceiling heights will be vertically segmented to encompass the arching shell structure. The special habitat will also include customizable lighting, temperature and sound controls which would help in regulating the daily routine, circadian rhythm and overall wellbeing of the crewmembers. Mars Dune Alpha will also muddle up fixed and moveable furniture which would allow crewmembers to recognize the habitat according to their daily needs.

Life in Mars Dune Alpha will give its occupants an expected experience of living on the Red Planet.

Life in Mars Dune Alpha will give its occupants an expected experience of living on the Red Planet.

Mars Dune Alpha is BIG’s third project that advances the exploration of space following Project Olympus, which is another joint venture with ICON and the first off-world construction system to support future exploration of the moon.

The special habitat will also include customizable lighting, temperature and sound controls which would help in regulating the daily routine, circadian rhythm and overall wellbeing of the crewmembers.

The special habitat will also include customizable lighting, temperature and sound controls which would help in regulating the daily routine, circadian rhythm and overall wellbeing of the crewmembers.

Project details

Size: 1,500 sq ft

Location: Johnson Space Centre, Houston, Texas

Client: ICON

Collaborators: NASA, ICON (Construction and design), Fort Structures (Structural engineer), PEI Point Energy Innovations (MEP)

Partners-in-Charge: Bjarke Ingels and Martin Voelkle

Associate-in-Charge: Michelle Stromsta

Project leader: Julian Ocampo

Project architect: Stephanie Mauer

Team: Isa Akerfeldt-Howard, Peter Sepassi, Mateo Fernandez and Andrea Hektor

Photograph courtesy: BIG and ICON

Video credits: ICON and BIG