Other than water, concrete is one of the highly used substances in today’s time. Alongside roads and building structures, nearly 70 per cent of the world’s man-made marine structures such as jetties, breakwaters, harbour walls and sea defences are built with concrete. These structures do not capture ecosystem services, thereby affecting marine life. To overcome the challenge of rising concrete consumption, ECOncrete ideated a sustainable solution for the structure as well as the environment.

With the help of biomimicry and ecological engineering ECOncrete designs concrete infrastructure to regenerate native marine life.

With the help of biomimicry and ecological engineering ECOncrete designs concrete infrastructure to regenerate native marine life.

With the help of biomimicry and ecological engineering ECOncrete designs concrete infrastructure to regenerate native marine life, reduce ecological footprints while also making infrastructure stronger and exceeding international industry standards. Titled COASTALOCK, ECOncrete’s patented technology invites species like oysters, corals, seaweed, algae and rehabilitates habitats for fish and even octopi, generating a huge carbon sink and strengthening the overall structure. These modular building blocks of marine infrastructure provide coastal defence against powerful forces of water.

COASTALOCK, ECOncrete’s patented technology, rehabilitates habitats for marine species, generates a huge carbon sink and strengthens the overall structure.

COASTALOCK, ECOncrete’s patented technology, rehabilitates habitats for marine species, generates a huge carbon sink and strengthens the overall structure.

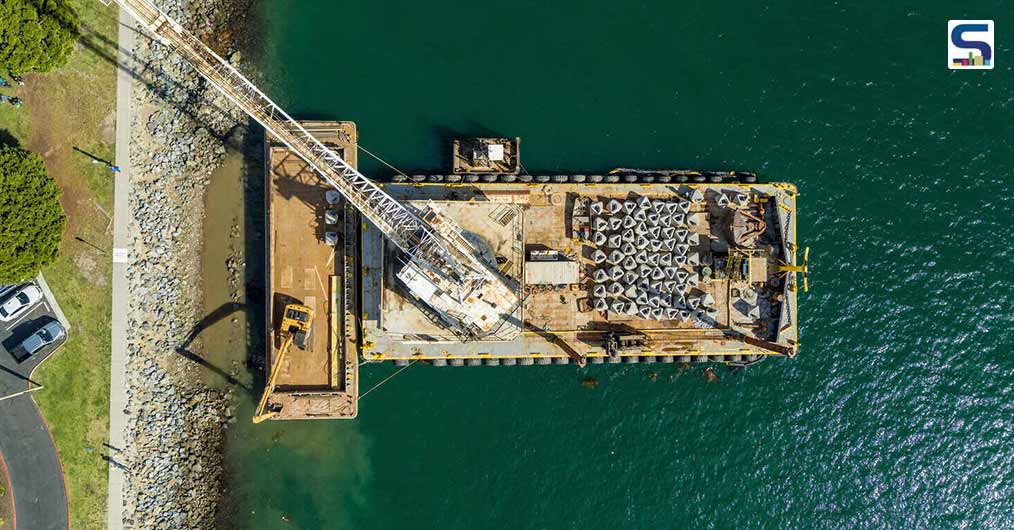

Throughout the design process, ECOncrete works closely with industry leaders, ranging from concrete machinery providers and coastal construction such as BESSER and BAM, to concrete and cement giants such as Holcim and world-leading marine engineering firms, to bring the designs to the mass market. During the development process of the COASTALOCK solution, ECOncrete had formed a partnership with the Port of San Diego, who had commissioned a pilot project to protect Harbor Island.

Equipped with an interlocking single-layer armour unit, COASTALOCK technology provides shoreline stabilization.

Equipped with an interlocking single-layer armour unit, COASTALOCK technology provides shoreline stabilization.

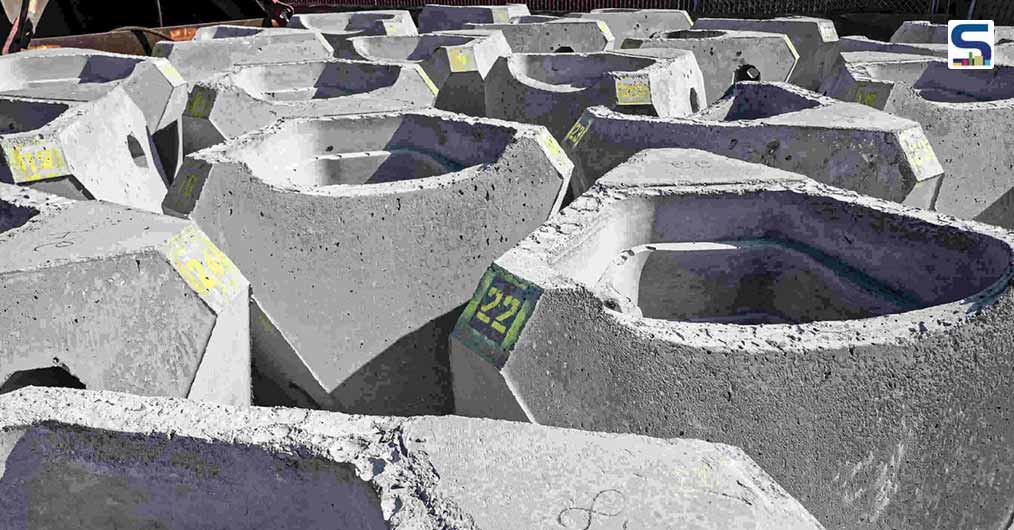

Prior to the partnership, Harbor Island’s shoreline protection such as the riprap rock mound had offered a very limited habitat value. To match the needs of the project, ECOncrete designed a product to balance the technical requirements of the unit along with the biological requirement of the local species – with the outcome being COASTALOCK. The project installed 72 interlocking armour units to increase both the structural and biological performance of the shoreline protection.

Its design retains traditional concrete’s fundamental strength and durability as it effectively protects the coastline without sacrificing the local environment and biodiversity.

Its design retains traditional concrete’s fundamental strength and durability as it effectively protects the coastline without sacrificing the local environment and biodiversity.

Equipped with an interlocking single-layer armour unit, COASTALOCK technology provides shoreline stabilization. Its product design gives it the adaptability to be used anywhere where conventional single-layer armour is needed such as in breakwaters, revetments and riprap embankments, in full replacement of conventional concrete armour. Additionally, it fits the unique properties of the coastline as the steeper slopes facilitate the interlocking of the units. Its design retains traditional concrete’s fundamental strength and durability as it effectively protects the coastline without sacrificing the local environment and biodiversity. The unique texture of the concrete acts as a growth point for marine species.

The admixture is made of nearly 90 per cent recycled and by-product materials.

The admixture is made of nearly 90 per cent recycled and by-product materials.

Furthermore, the calcitic organisms draw CO2 from the water to build their shells, transforming a passive structural unit into an active carbon sink. These organisms also build up a CaCO3 (calcium carbonate) layer – a bioprotection covering the units in a living armour that adds weight and stability, buffering hydrodynamic forces and chlorides. Also, the solution reduces the level of CO2 emitted as compared to traditional concrete, as the admixture is made of nearly 90 per cent recycled and by-product materials. The bio-enhancing admixture promotes biocalcification and photosynthesis, offsetting up to 2 tonnes of CO2 for every km of infrastructure annually – the equivalent of 100 trees.

ECOncret’s COASTALOCK is cost-effective and can be installed in three days.

ECOncret’s COASTALOCK is cost-effective and can be installed in three days.

ECOncret’s COASTALOCK is cost-effective and can be installed in three days which is easy with an attractive outcome. Weighing 3.5 tonnes, the armoured fibre reinforced concrete unit reduces the harmful effect of concrete on the ecosystem, increases biogenic build-up, complies with and exceeds the industry standards.

Image credits: ECOncrete