A team of researchers from the Natural Science Centre for Basic Research and Development, Hiroshima University recently published their findings on finding a scalable method to fabricate quantum dots that have been developed in a way to recycle rice husks to create the first silicon quantum dot (QD) LED light.

Nearly 100 million ton of rice husk waste is generated globally each year while separating the grain from the husks. The new method reportedly transforms agricultural waste into state-of-the-art light-emitting diodes in a low-cost, environmentally friendly way. According to Ken-ichi Saitow, lead study author and professor of chemistry, Hiroshima University, “Since typical QDs often involve toxic material such as cadmium, lead or other heavy metals, environmental concerns have been frequently deliberated when using nanomaterials. Our proposed process and fabrication method for QDs minimize these concerns.”

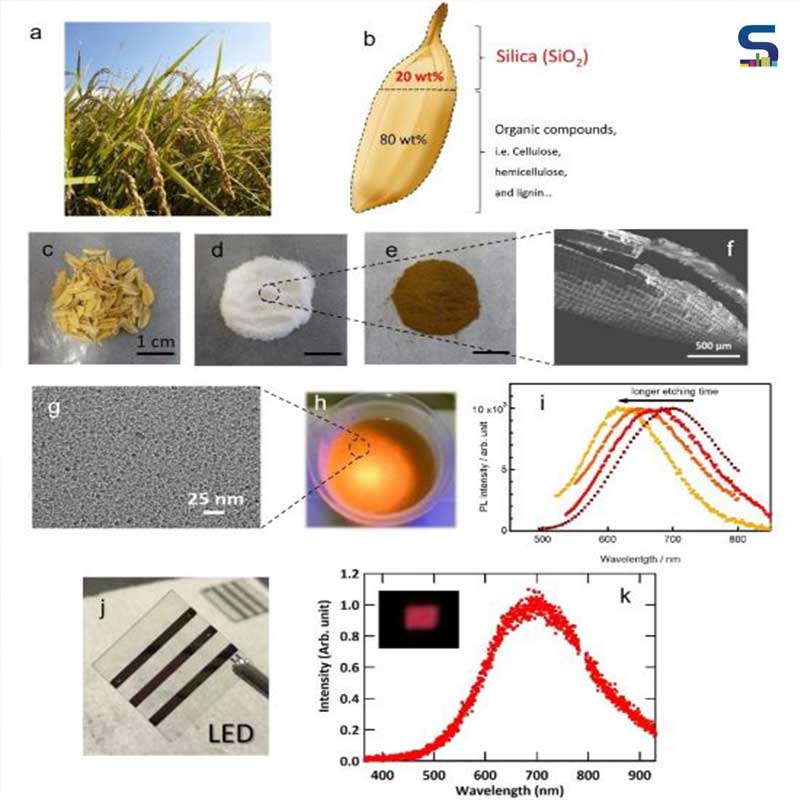

Understanding porous silicon

Discovered in the 1950s, scientists have explored the uses of porous silicon (Si) in applications in lithium-ion batteries, luminescent materials, biomedical sensors and drug delivery systems. Porous silicon has photoluminescence properties, stemming from its microscopic (quantum-sized) dot structures that serve as semiconductors. It is non-toxic and is found abundantly in nature. On account of the environmental concerns surrounding the current quantum dots, the research team explored a new route to fabricate quantum dots that have a positive environmental impact. The result was using waste rick husks as it is an excellent source of high-purity silica (SiO2) and value-added Si powder.

The process

The researchers – including Honoka Ueda, Shiho Terada and Taisei Ono along with Saitow – used a combination of milling, heat treatments and chemical etching to process the rice husk silica. By burning off organic compounds of milled rice husks, the team milled rice husks and extracted silica powders. Thereon, they heated the silica powder in an electric furnace to obtain porous silicon powders via a reduction reaction. The outcome was that of a purified porous silicon powder that was further reduced to 3 nanometer in size by chemical etching. Lastly, the surface had been chemically functionalized for high chemical stability and high dispersivity in solvent, with 3 nm crystalline particles to produce the SiQDs that luminesce in the orange-red range with high luminescence efficiency of over 20 per cent. Confirming the non-toxic quality of silicon that makes it an attractive alternative to current semiconducting quantum dots that are available today, Saitow adds, “This is the first research to develop an LED from waste rice husks. The present method becomes a noble method for developing environmentally friendly quantum dot LEDs from natural products.”

The LEDs had been assembled as a series of material layers, where an indium-tin-oxide (ITO) glass substrate was the LED anode – a good conductor of electricity that is sufficiently transparent for light emission. Including the layer of SiQDs, additional layers had been spin-coated onto the ITO glass, while the material has been capped with aluminium film cathode. It is the chemical synthesis method that the team developed that has allowed them to evaluate the optical and optoelectrical properties of the SiQD light-emitting diode including the structures, synthesis yields and properties of the SiO2 and Si powders and SiQDs.

Future plans

The team is in plans to develop higher efficiency luminescence in the SiQDs and the LEDs, for which they will explore the possibility of producing SiQD LEDs. Additionally, the researchers also suggest that the method they have developed could be applied to other plants that contain SiO2 such as sugarcane, bamboo, wheat, barley or grasses.

Image credits: Hiroshima University