56 Hours studio introduced its limited edition OO Stool which is made of a single material – plastic waste sourced from a chocolate factory. In collaboration with Rotterdam-based Plasticiet, a company that produces materials from post-industrial plastic waste, 56 Hours used discarded polycarbonate moulds from the factory to design OO Stool X Plasticiet.

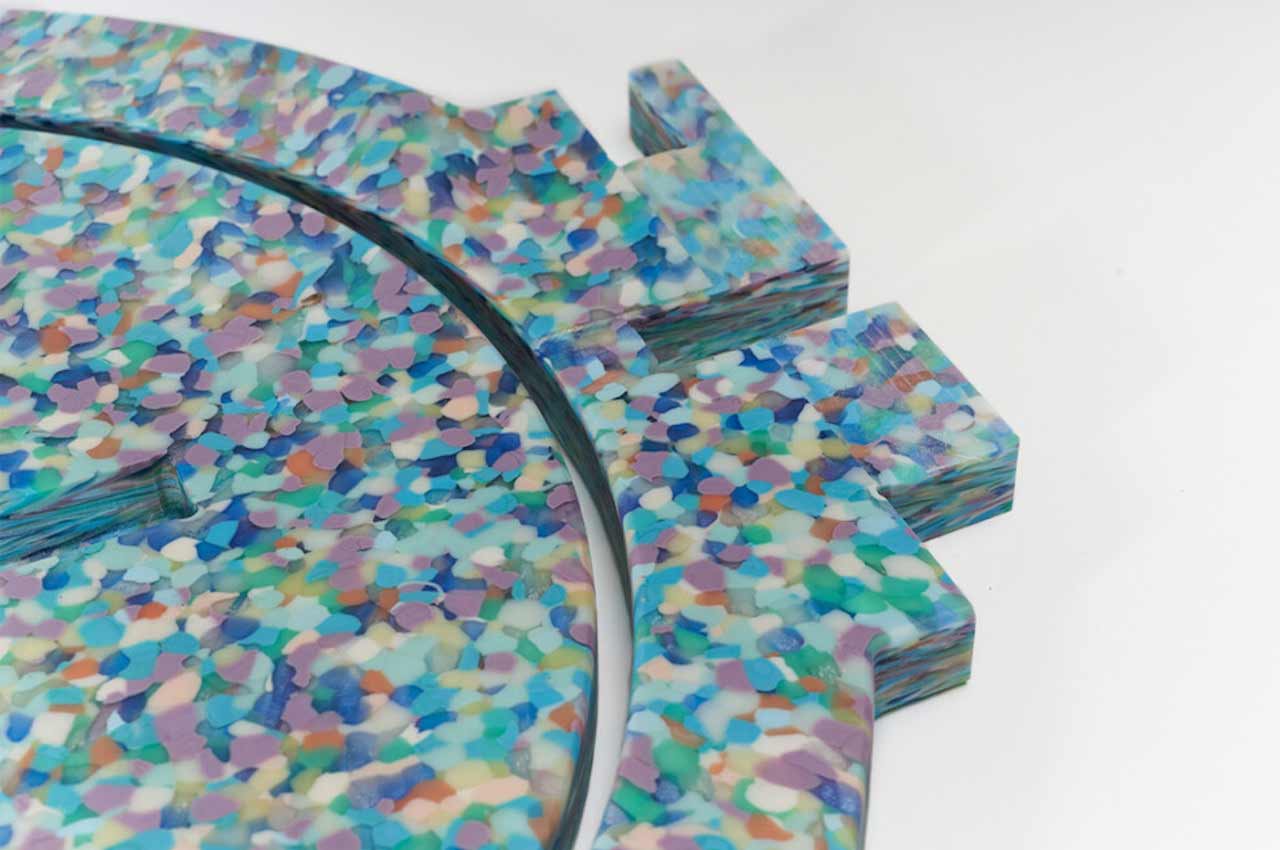

Focused on reducing the waste of the sheet material by eliminating the negative space between the parts of the stool, the furniture has been designed in 2D. Rejected polycarbonate moulds from the factory are shredded, melted and compressed into solid sheets by Plasticiet.

A hammer, which is cut out from the same sheet, is the only tool that is needed for assembling the stool. The durable flatpack stool can be easily assembled without the need for screws or nails. Inspired by the Japanese craft of joinery, the design of the stool seamlessly holds the furniture together, thereby allowing easy assembling. Additionally, it also adds value to the stool by benefiting from using a single material, durability and simple shape. To minimize the leftover parts, additional objects have been designed to fit onto the board.

The OO Stool X Plasticiet can be flat for packaging and transportation, and is easy to store.

Image credits: 56 Hours