Honext, a Barcelona-based startup, has developed a sustainable construction board material that is made out of a combination of enzymes and cellulose which is sourced from waste streams of paper production. Know more on SURFACES REPORTER (SR).

Honext’s ‘untapped resource’ is the cellulose residue taken from cardboard and paper waste that is generated at paper mills. The paper and cardboard have been through several reuse cycles. This allows the cellulose fibres to appear short and bound together which can be later turned into paper again.

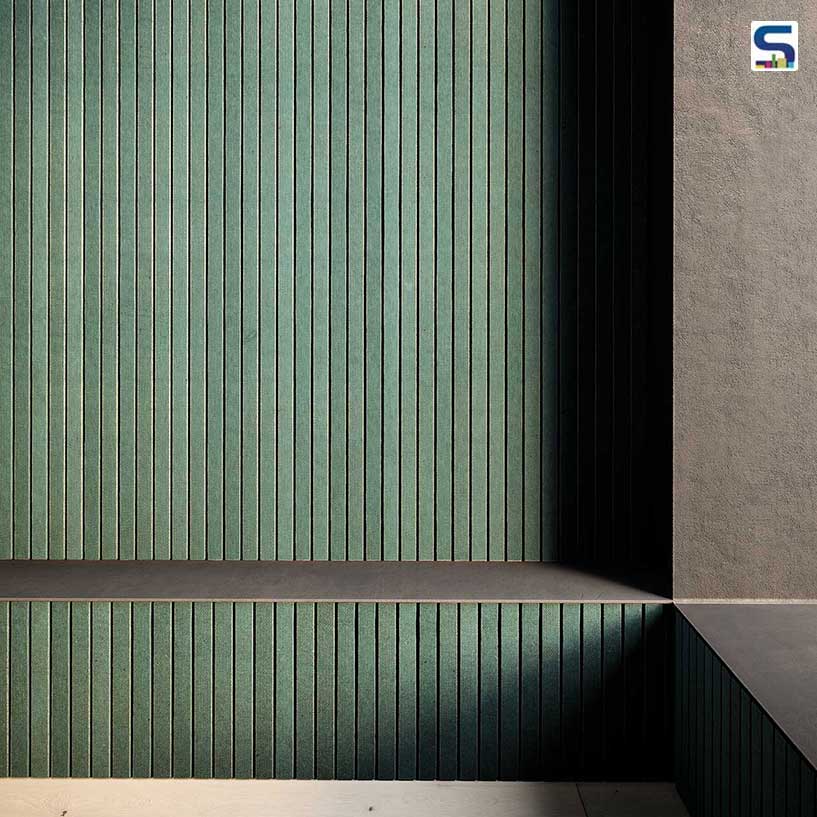

The fibres generally end up in landfills or are burnt, resulting in the generation of 7 million ton of waste globally each year. Honext saves this material from turning into waste by using it in construction boards, interior partitioning and cladding. Depending on the quality of waste, Honext mixes the waste cellulose fibres with water and enzymes. The mixture contains 50 per cent to 75 per cent of paper sludge with 50 per cent to 25 per cent of cardboard waste. Certain enzymes are included during the production process. With the help of these enzymes, which are a critical part of the process, Honext creates stronger bindings between the short cellulose fibres without having to use non-recyclable resins. During the process, the length of the fibre, which is less than 5 mm, cannot hold together without resins or any other additives or glues which are used in the construction industry. To improve the board's UV resistance, non-toxic additives are added to the mixture. The mixture is compressed and shaped into a wet board right before the board is passed through a drying tunnel. Upon drying, the remaining water is evaporated through high airflow and temperature, leaving the sheets dry.

Honext’s method makes the board emissions-free. Unlike MDF and drywall, the cellulose boards do not emit harmful particles. They are lighter, flexible and have a greater sound absorption than regular boards. Going forward, Honext aims to make the production process of these boards carbon neutral.

Manufactured in the village of Vacarisses in the province of Barcelona, Spain, Honext's cellulose material is produced using gas and electricity which is generated from the digestion of the town's waste. As for the water which is used during the process, it is reused in a closed circuit.

Once the material has reached the end of its life, it is fed back into the production pipeline to create a new set of boards. This process also strips the material of any coating or finish applied by the constructor.

Image credits: Honext