Metal can be easily altered into an end number of shapes that can be used for different purposes through casting, machining, rolling and forging. However, each of these methods affects the sizes and shapes of the tiny crystalline grains that form the bulk metal such as steel, aluminium and other metals and alloys. A research at the Massachusetts Institute of Technology (MIT) has been carried out to study the formation of these crystal grains that are created during an extreme deformation process. Here is a detailed report on SURFACES REPORTER (SR).

What is recrystallization?

According to MIT professor and researcher Christopher Schuh, the new findings have the potential to improve the ways of processing only to produce better, more consistent properties such as hardness and toughness. Reported in the journal of Nature Materials, in a paper by former MIT post-doc Ahmed Tiamiyu, who is now an assistant professor at the University of Calgary; MIT professors Christopher Schuh, Keith Nelson and James LeBeau; former student Edward Pang; and current student Xi Chen have made the new findings possible by detailed analysis of images from a suite of powerful imaging systems. “In the process of making a metal, you are endowing it with a certain structure and that structure will dictate its properties in service,” comments Schuh, highlighting the smaller the grain size, the stronger the resulting metal. For the team, striving to improve strength and toughness by making the grain sizes smaller has been an overarching theme in all of the metallurgy, in all metals, for the past 80 years.

A variety of empirically developed methods for reducing the sizes of the grains in a piece of solid metal had been applied by metallurgists. They included various kinds of strain by deforming it in one way or another. However, it wasn’t easier to make these grains smaller.

Recrystallization process and experimentation

In the primary method of recrystallization, the metal is deformed and heated. This process creates small defects throughout the portion. These defects are highly disordered and all over the place, inform Danae and Vasilis Salapatas Professor of Metallurgy Christopher Schuh. He further explains the unique aspect of the finding which is determining how this process takes place at very high speed and on the smallest scales. Generally, typical metal forming process such as forging or sheet rolling is fast, however, this new finding aims at processes that are several orders of magnitude faster.

For this, the team used a laser to launch the metal particles at a supersonic speed. This industrial process includes high-speed machining, high-energy milling of metal powder and a cold spray method that is used for forming coatings. During the experiments, the team tried to understand the recrystallization process at the same extreme rates. Since the rates are high, the subject is untouched by any systematically understanding. The laser-based system had been used to shoot 10 micrometer particles at a surface where each particle had been shot one at a time. This assisted the team to understand and measure how fast they are really going and how hard they could be hitting. Upon shooting the particles at a fast speed, the team then cut them open to observe the evolution of the grain structure down to the nanometer scale under a variety of sophisticated microscopy techniques at MIT.

The outcome

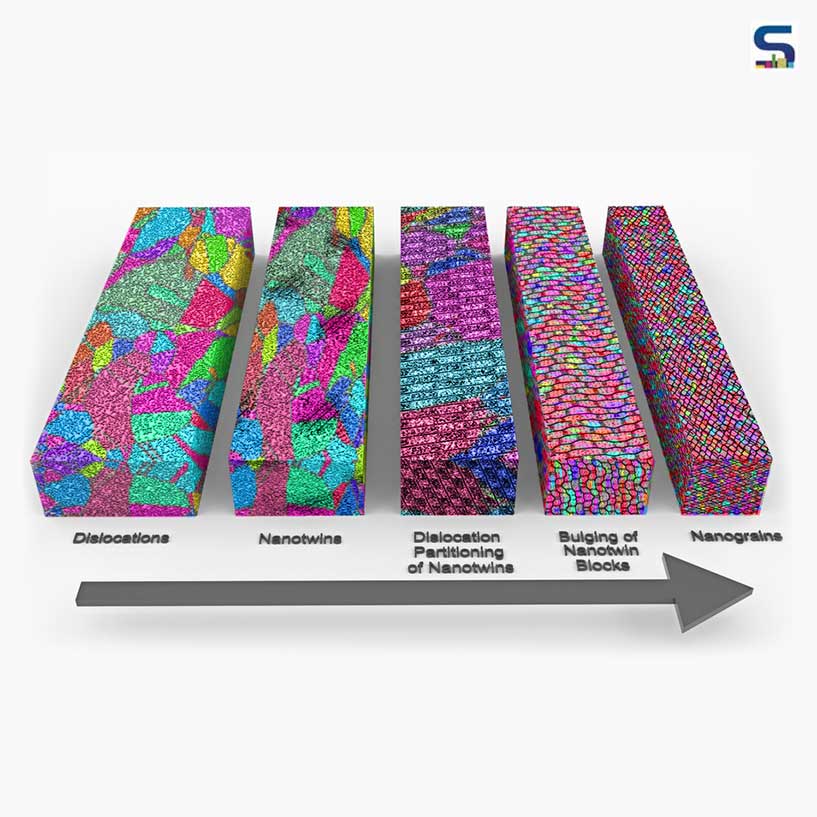

The result of the experimentation, according to Schuh, is a novel pathway where the grains formed at a nanometer scale. Called the nano-twinning assisted recrystallization, the new pathway is a variant of the known phenomenon in which the metals twin. Here a particular kind of defect is observed where part of the crystalline structure flips its orientation. These flips appear in a symmetrical mirror and stripped pattern where the metal flips its orientation and flips back again in a herringbone pattern. It had been observed that the higher the rate of these impacts, the more this process took place, which further created smaller grains similar to the nanoscale twins that broke up into new crystal grains.

With the help of copper, the process of bombarding the surface with these tiny particles at high speed increased the metal’s strength about tenfold, which is not a small change in properties. The team also applied a wide range of imaging and measurements to the exact same particles and impact sites which gave them a multi-model view.

Since the new findings guides and directs the degree of deformation requirement and the process of deformation in relation to its speed and temperature, they can be directly applied to real-world metal production. Unlike hypothetical lines, the study’s graph is produced from experimental work.

Image credits: MIT