Betolar recently launched its first low-carbon concrete products made out of Geoprime for the Indian construction market. The next-generation, low-carbon solution, Betolar’s Geoprime is a sustainable alternative to cement. Know more on SURFACES REPORTER (SR).

One of the most polluting sectors rapidly contributing to the global CO2 emission is the construction industry. And the most significant problem of this industry is the usage of cement in concrete work, which is the root case for creating a significant carbon dioxide load.

Understanding Geoprime

The Finland-based materials technology company aims at transforming industrial side streams from the energy, mining, steel and forestry sectors into a low-carbon, cement-free building material with the same properties as concrete but with lesser carbon footprint.

- Geoprime is a solution for a cement-free environment.

- It allows concrete manufacturers to create 100 per cent cement-free concrete by effectively utilizing industrial side streams such as fly ash and ground granulated blast furnace slag (GGBS).

- It has compressive strength, bending strength and splitting tensile strength that meet the requirements of a range of concrete products.

- It offers excellent sulphate resistance.

- Although comparable to the durability and strength of cement-based products, Geoprime outperforms traditional products with nearly 80 per cent lower carbon footprint.

- A pioneering solution for sustainable living environments, Geoprime is a reliable, safe and sustainable solution for all kinds of construction needs.

- Geoprime products are based on a geopolymer solution, which is an inorganic polymer that can be used for creating new materials.

- Products made out of Geoprime can be reused throughout their lifecycle as it is recyclable.

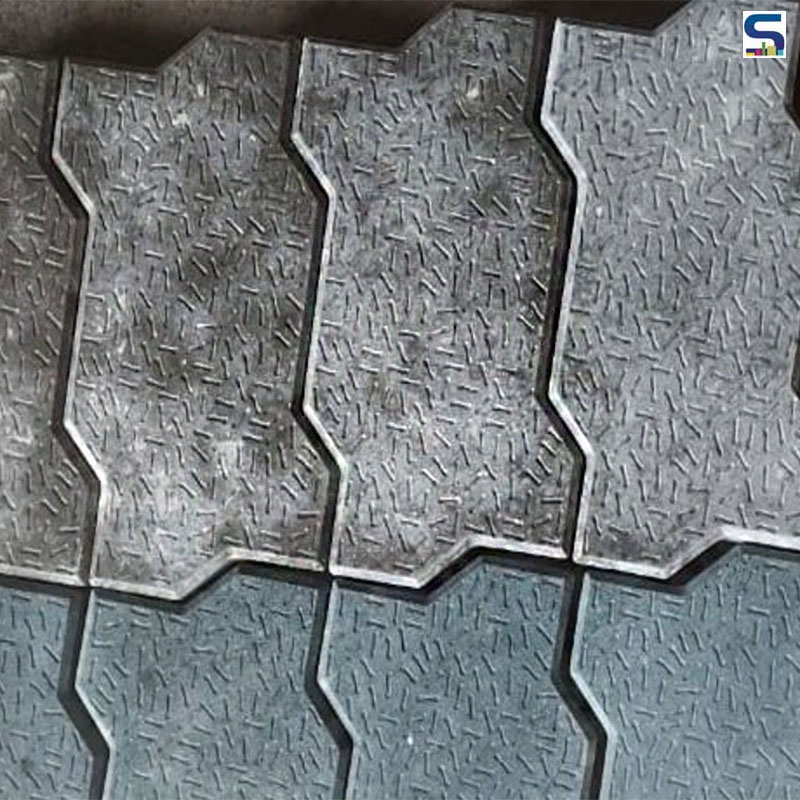

- Its application includes several types of concrete products in infrastructure construction, such as paving blocks, poles and construction blocks.