In a groundbreaking advancement toward sustainable construction, scientists at Northwestern Engineering have developed a novel carbon-negative building material by utilizing three abundant and accessible resources, including seawater, electricity and carbon dioxide (CO2). This innovative material not only helps combat climate change but also has the potential to transform the construction industry by creating valuable, eco-friendly alternatives to traditional materials like concrete, cement, plaster and paint. Here is a detailed report on SURFACES REPORTER (SR).

Northwestern’s new approach not only locks away CO2 permanently but also converts it into high-value materials that can be integrated into essential building applications.

A Breakthrough in Green Construction

As global temperatures continue to rise, many researchers are turning to carbon capture technologies that store CO2 underground. While beneficial, these methods often fail to capitalize on the enormous potential of the captured carbon. In contrast, Northwestern’s new approach not only locks away CO2 permanently but also converts it into high-value materials that can be integrated into essential building applications. Additionally, the process generates hydrogen gas, a clean energy source with wide-ranging uses, including fuel for transportation.

The findings were published on March 19 in the journal Advanced Sustainable Systems. The project is led by Alessandro Rotta Loria, Louis Berger Associate Professor of Civil and Environmental Engineering at Northwestern’s McCormick School of Engineering. Co-authored by Jeffrey Lopez, assistant professor of chemical and biological engineering at McCormick, the research also involved postdoctoral fellow and lead author Nishu Devi, PhD students Xiaohui Gong and Daiki Shoji, and former graduate student Amy Wagner. The study was conducted in collaboration with Cemex, a global building materials leader focused on sustainable innovation.

From Pollution to Construction

The process draws inspiration from marine life, particularly how corals and mollusks use natural metabolic energy to form their calcium carbonate shells. In this engineered adaptation, the researchers applied electricity instead of biological energy to initiate a similar mineralization process. Electrodes are placed into seawater, and a low electrical current is applied. This causes the water molecules to split into hydrogen gas and hydroxide ions. Simultaneously, CO2 gas is bubbled into the seawater, raising the concentration of bicarbonate ions. These ions then react with naturally occurring calcium and magnesium in the seawater, forming solid minerals like calcium carbonate and magnesium hydroxide.

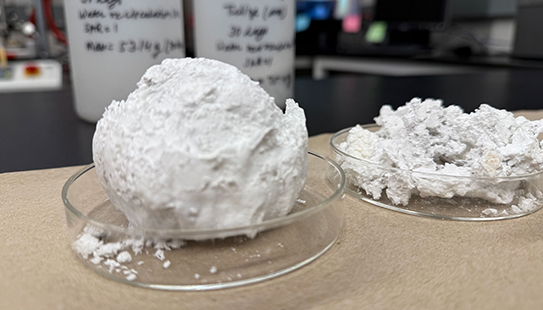

These minerals act as effective carbon sinks where calcium carbonate locks in carbon directly, while magnesium hydroxide captures CO2 through further reactions. The result is a sand-like material that mimics the function of traditional construction aggregates but with a significantly reduced environmental impact.

By adjusting variables such as electrical voltage, CO2 injection timing and seawater recirculation, researchers can tailor the properties of the final product.

Sustainable Construction

One of the key advantages of this method is its versatility. By adjusting variables such as electrical voltage, CO2 injection timing and seawater recirculation, researchers can tailor the properties of the final product. This flexibility allows the material to vary in density, porosity and composition, making it suitable for diverse applications, from substituting sand and gravel in concrete to use in manufacturing cement, paint, and plasters.

Crucially, the material retains strength and stability when used in structural applications. In fact, depending on its composition, it can sequester over half its own weight in CO2. For instance, a mixture containing equal parts calcium carbonate and magnesium hydroxide can store more than 0.5 metric tons of CO2 per metric ton of material.

Rotta Loria envisions these materials being produced in modular reactors located onshore, near concrete and cement manufacturing facilities. This setup would allow full control over the chemistry involved while preventing disruption to marine ecosystems. The treated water would be safely returned to the ocean only after rigorous environmental evaluation. This method presents a promising solution to the significant environmental footprint of the cement industry, which is responsible for approximately 8 per cent of global CO2 emissions. By integrating CO2 into the very materials used to build infrastructure, the process introduces a powerful model of circular sustainability. Not only does it help decarbonize construction but it also repurposes CO2 from a harmful emission into a valuable resource.

The study, titled Electrodeposition of Carbon-Trapping Minerals in Seawater for Variable Electrochemical Potentials and Carbon Dioxide Injections, was supported by Northwestern University and Cemex as part of a larger effort to pioneer sustainable construction practices for the future.

Image credit: Northwestern University