Kajaria Ceramics is one of the largest manufacturers of ceramic/vitrified tiles in India. The globally-renowned brand is bringing an extensive range of vitrified and ceramic solutions to its patrons and has been enabling its customers to design a dream home out of their spaces. Started with 1 mn sqm, today, the company has an annual aggregate capacity of 70.40 mn sqm, distributed across eight plants - Sikandrabad in Uttar Pradesh, Gailpur & Malootana in Rajasthan, Vijayawada & Srikalahasti in Andhra Pradesh and three plants in Gujarat. Founded 30 years ago, Kajaria has grown stronger owing to its team's continued hard work, dedication, creativity, and design ability, along with the innovations and patronage from its discerning customers. The company currently offers more than 2800 options in ceramic wall & floor tiles, vitrified tiles, designer tiles, and much more. Recently, the company has launched its new product- Vitronite. In an exclusive interview with the Vertica Dvivedi, Editor-in-Chief, SURFACES REPORTER MAGAZINE, Mr B G Vyas, the Chief Operating Officer at Kajaria Ceramics updates about the new product, its specialities, and why it is an authentic replacement of Granite & Marble slabs.

What is the thought behind the launching of Vitronite slabs?

India has a huge market in the tabletop segment without the presence of an organized player. Due to the change in lifestyle and emerging category of luxury house, customer perception towards the modern kitchen is changing. Therefore, the end users are looking for a product which is technically superior, cost effective and available with a wide range of choices. Three major aspects behind the launch of Vitronite:

1. Tremendous pull of the brand Kajaria and a wide distribution network which will help us in the market penetration and further development in this emerging category.

2. Vitronite has widened our product portfolio and given us scope to explore potential of new application areas.

3. Being a technically superior product -To summarize – the product offers value for money in its category and thus our descriptive product punch line is Vitronite: One Surface – Many Possibilities.

Vitronite is a ready to use material, pre-sized, pre-polished & with huge potential. No branded product is available in this category. It has great opportunity for designers, dealers and distributors.

How is the product positioned in the market?

Vitronite has two positioning statements, i.e., Firstly as a New Age Kitchen tops for Modern Kitchen and secondly, as the New Age Granite & Marble.

Why is the size significant in Vitronite?

Vitronite is currently available in 800mm X 2400mm and having 15mm thickness. A higher thickness provides extra strength and durability to the product. Technically, we can say that the strength of this 15mm thick vitrified slab is almost two times more than the granite.

The thickness adds to natural beauty along with having functional benefit to the edges for profiling (bullnose). Also, due to the higher thickness, it is ideal for high traffic areas including Airport, mall, school, hospital, and corporate offices etc.

Vitronite has allowed us to enter the hitherto untapped and a vast natural stone market. It is an authentic replacement of Granite and all types of marbles, including Italian Marb

How many SKUs are on the offer?

At present, aesthetically, in line with approvers' (Architect and Interior Designer) choice, we are having 35 SKUs. Though, this itself is fairly good choice, yet we will bring in more options as we grow in this category.

How many variants are available?

At present, we are offering 5 variants in this segment viz.

a) Terrazzo (Homogenous Body)

b) Salt & Pepper (Homogenous Body)

c) Solid Colors (Homogenous Body)

d) Marbellite (Italian Marble Series)

e) Plain (Color Body

Tell us about the reach of Vitronite?

Vitronite is widely available at all our leading dealers across India. Kajaria has a strong supply chain so timely supply is one of our strength. In fact, granite is currently facing a severe issue of availability of good quality material. In addition, it also does not have standardized specification like Vitronite.

Since these tiles appears large, how easy it is to handle and lay?

These tiles are securely packed and delivered. Hence, there is an ease of handling. As far as laying is concerned, a trained mason who is experienced in granite or marble slabs laying, would be able to lay them more easily and in lesser time. A correct measurement of the surface and the application area with the normal wastage percentage factored is recommended so that the wastage can

be avoided.

How to clean & Maintain Vitronite Slabs/floors?

Vitronite countertops /Floors can be washed with a warm water and detergent and dry it with a clean cloth. Also, avoid using hydrofluoric acid. If liquids are spilled, it must be cleaned immediately. The faster you clean and dry spills, the easier it is to remove stains. In addition, some stains/products cannot be removed by normal cleaning options and requires specific chemicals to clean up.

"A trained mason who is experienced in granite or marble slabs laying would be able to lay them more easily and in lesser time."

Does Vitronite require surface polishing after laying?

Vitronite surface does not require any polishing after laying as it is a ready to use product - pre-sized, pre-cut, pre -polished, and thus it is an authentic replacement of Granite and all types of marbles, including Italian Marble.

How do you compare Vitronite with Quartz and Granite?

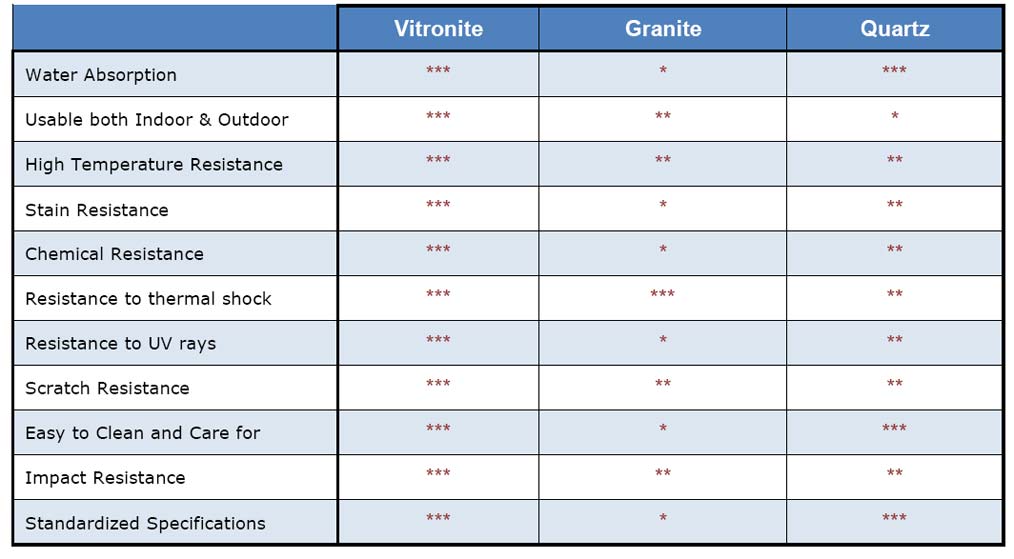

Vitronite is technically superior to granite and quartz, As explained in the comparative chart below:

We feel that Vitronite is an authentic replacement of Granite & Marble slabs with its superior quality and standardized technical specifications. A decade earlier, Vitrified Tiles were launched which quickly took a huge share of marble & other natural stone flooring. Today, Vitrified tile rules the flooring segment and marble has a minuscule share. Similarly, in future, Vitronite Slabs are going to take over the granite/Italian Marble segment in a big way and there lies a huge opportunity to be tapped.

"It can be used in Kitchen as Tabletop, Bathroom vanity top / countertop, Staircase, Door or Window framing, External wall cladding, Bathroom wall cladding, TV units, Hard flooring etc."

How do you see Surfaces Reporter shaping up in the present times?

I have been associated with Surfaces Reporter since a decade, right from its beginning. You people are doing excellect work. You are taking the magazine in the best way and in the right direction.