Thanks to its seemingly endlessly recycled property, glass is often considered a sustainable product. However, the raw materials involved in it demand unmanageable energy consumption. One such raw material, limestone, has limited availability and is mined in gigantic mines with known problems. Additionally, the availability of soda is also changing dramatically due to climate change. Benedikt Peiroten of Studio Peipei came up with an energy-saving and waste-based glass that is made with pizza baker’s wood ash and seashells from restaurants.

As a part of his master's thesis in Design through New Materials at ELISAVA, Barcelona, From the Ashes is made with endless resources in the form of waste. Glass requires two main components, namely, sodium carbonate and calcium carbonate. Human production methods and climate change have severally affected the availability of these two materials alongside most of the industrial processes. As a flux, sodium carbonate lowers the melting point of sand. Upon extraction in salt lakes, it is manufactured using the Solvay process which requires a high level of water and energy, and quicklime which is obtained by heating rare limestone to 1000° C. Many natural salt lakes are also shrinking due to global warming.

To extract calcium carbonate, limestone is mined in large mines. The annual usage of limestone, which has been formed over hundreds of millions of years, is 5000 million ton at present. The extraction of limestone from mines further causes environmental impacts. That said, reports suggest that the largest mine in Europe will be exhausted in 2048.

Peiroten’s From the ashes discovers infinite supply chains by using waste. With little effort, potassium carbonate can be extracted from wood ash. Not only it is a flux but it also lowers the melting point in the same way and also creates intense colour tones that offer a unique character to the object. However, the seashells provide the required calcium carbonate that helps the glass to attain its usual hardness.

In the end, the process demands sand, which is bought in. Once melted, the glass enters the endless recycling cycle with no by-products or waste. Peiroten informs us that it can be fused again and again, or it can be ground to sand again. Since the glass is made from all-natural ingredients with no metal oxides or chemicals, it can be given back to nature as the ingredients are harmless.

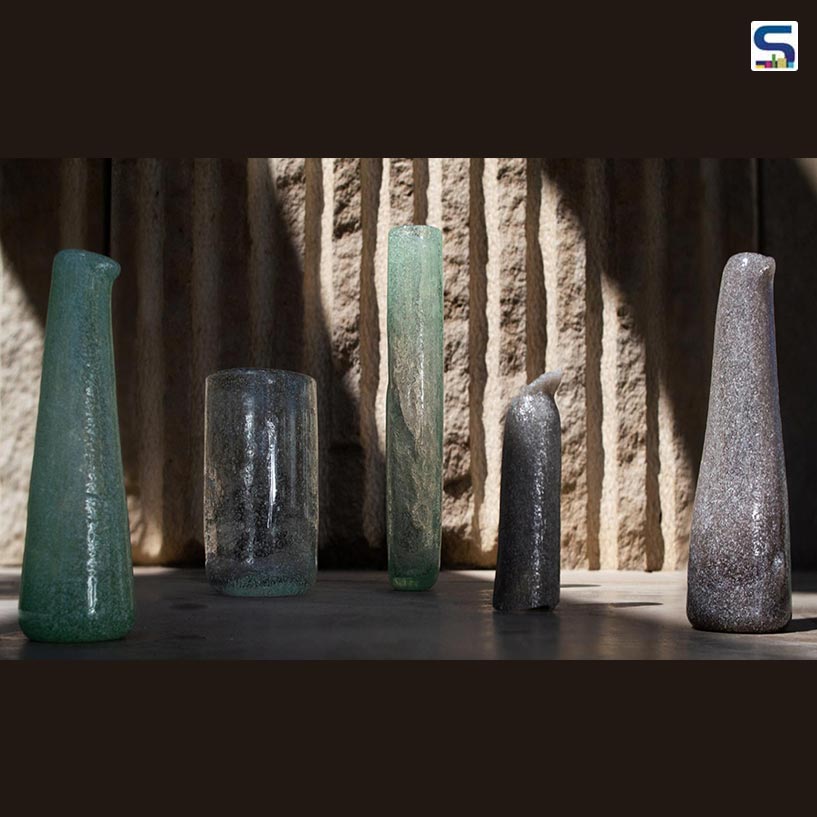

Image credits: Studio Peipei