Cement is the second most-consumed material on the earth behind water, a staple of building construction all over the world. Today, its production accounts for 7% of global carbon emissions. A large part of which results from the burning of quarried limestone for the production of cement. To make cement production carbon-neutral, CU Boulder based researchers have developed a way to make sustainable concrete by adding microalgae to the mixture. The method is not only carbon neutral but could even prove carbon negative as it can pull out CO2 from the air and store it within the concrete. Read SURFACES REPORTER (SR)’s complete report below:

Also Read: World’s First Carbon-Neutral Bioceramic Geodesic Dome to Last for 500 years | Geoship

Wil Srubar holds a sample cube of concrete that contains biogenic limestone produced by calcifying macro- and microalgae. © Glenn Asakawa, CU Boulder

“For the industry, now is the time to solve this very wicked problem. We believe that we have one of the best solutions, if not the best solution, for the cement and concrete industry to address its carbon problem,” says WIL SRUBAR, lead principal investigator on the project and associate professor in Civil, Environmental and Architectural Engineering and CU Boulder’s Materials Science and Engineering Programme

The study of creating one of the most sustainable cement is done by The CU Boulder engineers and their colleagues at the Algal Resources Collection at the University of North Carolina Wilmington (UNCW) and the National Renewable Energy Laboratory (NREL). They have been rewarded for their innovative work with a $3.2 million grant from the US Department of Energy’s (DOE) Advanced Research Projects Agency-Energy (ARPA-E).

The Major Challenge

As the entire world is now aware of the disastrous effect of cement production in the environment, it is essential to find ways to mitigate its impact.

The lab process utilises calcifying microalgae to produce limestone and create a carbon neutral cement, as well as cement products which can slowly pull carbon dioxide out of the atmosphere and store it © Glenn Asakawa, CU Boulder

The lab process utilises calcifying microalgae to produce limestone and create a carbon neutral cement, as well as cement products which can slowly pull carbon dioxide out of the atmosphere and store it © Glenn Asakawa, CU Boulder

There are two ways through which cement production leads to CO2 emissions. One is through the chemical reactions that take place while treating limestone and other materials of the mix to create “clinker”, a main component of cement. The other comes from the burning of fossil fuels at very high temperatures.

The production of cement leads to hefty greenhouse gas emissions in the atmosphere. But as it is the most widely used material on the earth due to its affordability, sturdiness and reliability, it seems to be the most preferred material in the construction industry for years to come.

Student working in the Living Materials Laboratory

Student working in the Living Materials Laboratory

Hence, it is vital to find a substitute for this. And that’s why many scientists and engineers have been experimenting with ways to create cement more sustainable by using other substitute materials in the mix. Or looking for ways to minimize or absorb greenhouse gasses released during the production process. But as of now, all the methods used to create sustainable cement are found expensive.

Cement Made Out of Microalgae

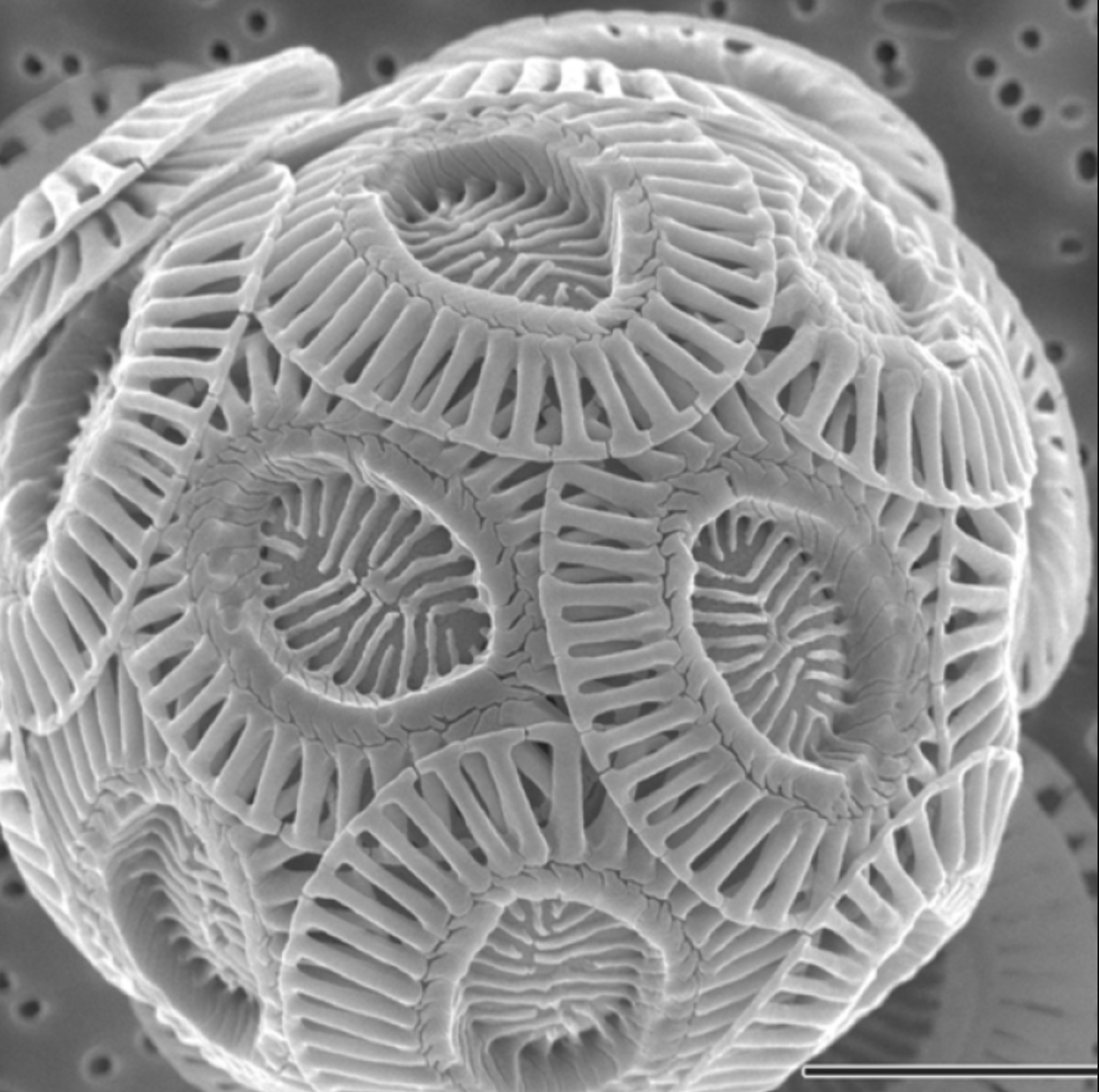

The researchers at CU Boulder have used microalgae called coccolithophores found in the oceans to create eco-friendly concrete. On observing the oceans from space or a plane, one can see big patches of bright turquoise water. These are single-celled microalgae blooms. These little creatures are covered in microscopic plates made of calcium carbonate, the mineral that creates the skeletons and shells of several sea organisms.

Aerial view of the Black Sea | The coccolithophore has been part of the Black Sea ecology for millennia, and in the summer these calcite-shedding phytoplankton can color much of the Black Sea cyan. © Nasa Goddard Space Flight Center

Aerial view of the Black Sea | The coccolithophore has been part of the Black Sea ecology for millennia, and in the summer these calcite-shedding phytoplankton can color much of the Black Sea cyan. © Nasa Goddard Space Flight Center

When exfoliating these plates, microalgae not only make the ocean surface look aqua, but they also send huge amounts of carbon to the deep ocean. Carbon is the main component of calcium carbonate or limestone.

The researchers used microalgae to grow calcium carbonate and turn it into a limestone alternative, which helps to create eco-friendly concrete.

A scanning electron micrograph of a single coccolithophore cell, Emiliania huxleyi © Wikimedia Commons, Alison R Taylor, University of North Carolina Wilmington Microscopy Facility

Though like normal limestone, this substitute still needs to be heated and therefore releases carbon dioxide into the air. However, it comparatively releases less carbon dioxide to the environment as it is not required to be quarried. Further, it captures at least as much carbon from the atmosphere as is produced while making cement.

The other advantage is that these tiny creatures produce calcium carbonate very fast, which means an increase in supply.

Laying the foundation for the future of carbon-zero buildings

It is still unknown how cost-effective this method would be compared to old cement production methods. But the team of scientists is planning to make the process more efficient by using strain selection and the growing process.

Source: University of Colorado Boulder

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

Micro Cement Brick is Grown from Bacteria

Useful Everyday Objects Made From Recycled Plastic Materials | Plastplan

Artificial Material Developed to Reduce Glacial Ice Melt | SR Material Update

And more…