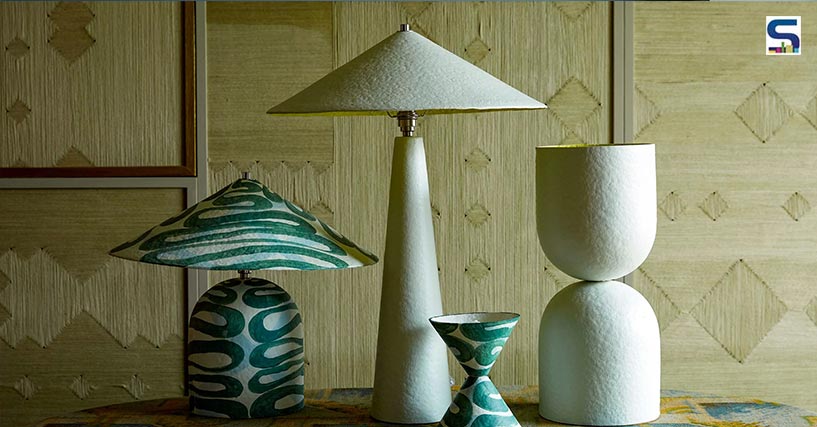

London-based Palefire Studio recently launched a group of sculptural lamps that are made from modular paper pulp. Encapsulating the glory of historical art and design movements, the U/V Collection is based on U and V shapes. Know more about the project on SURFACES REPORTER (SR).

Encapsulating the glory of historical art and design movements, the U/V Collection is based on U and V shapes.

Encapsulating the glory of historical art and design movements, the U/V Collection is based on U and V shapes.

Comprising modular pieces that are moulded from recycled paper pulp, the U/V Collection is the first release from the studio which is founded by multi-disciplinary creative Rowena Morgan-Cox. Inspired by art movements, the modules of the collection have been designed to be stacked in varied formations to create a wide selection of lamps.

Palefire Studio’s modular system aims at reducing waste by encouraging the reuse of each piece to design a new lamp.

Palefire Studio’s modular system aims at reducing waste by encouraging the reuse of each piece to design a new lamp.

Palefire Studio’s modular system aims at reducing waste by encouraging the reuse of each piece to design a new lamp. Even its smallest cone can be used as the shade of Diabolo lights or the ceiling rose of pendant lights. The Totem floor lamp is composed of 14 stacked parts. The U/V Collection is refined and pared back that is crafted out of the least number of moulds. At a workshop in Barcelona, these modules are manufactured in small batches and painted with low VOC (volatile organic compound) paints.

Since the lights are made to order, the hand painting process begins only when the sale has been confirmed.

Since the lights are made to order, the hand painting process begins only when the sale has been confirmed.

Once printed paper and cardboard boxes are collected, the paper waste is processed at a small, family-run workshop that has been manufacturing paper pulp since the 1890s outside Barcelona. The paper waste is injected into moulds. The moulds are then left outside to dry in the heat. Reportedly, the remaining of the manufacturing process takes place in the UK.

The paints are made in Iceland and Sweden by using 100 per cent geothermal energy and have the lowest VOC rating in the UK.

The paints are made in Iceland and Sweden by using 100 per cent geothermal energy and have the lowest VOC rating in the UK.

The shapes are hand-painted in Palefire Studio in Vanguard Court, South East London and assembled by a specialist in South London. The lights are then coated with paint that is produced by the manufacturer that uses geothermal, hydropower and wind energy to power their plants. Since the lights are made to order, the hand painting process begins only when the sale has been confirmed. This also allows the studio to limit its stock waste. The hand painting technique not only makes each product look distinct but it also extends the lifespan of the product. The paints are made in Iceland and Sweden by using 100 per cent geothermal energy and have the lowest VOC rating in the UK. As for the metal and the electrical components, they are procured from a small family-run factory in Birmingham, where waste filings are collected and put back into the system.

Photographs: Kim Lightbody; Courtesy: Palefire Studi