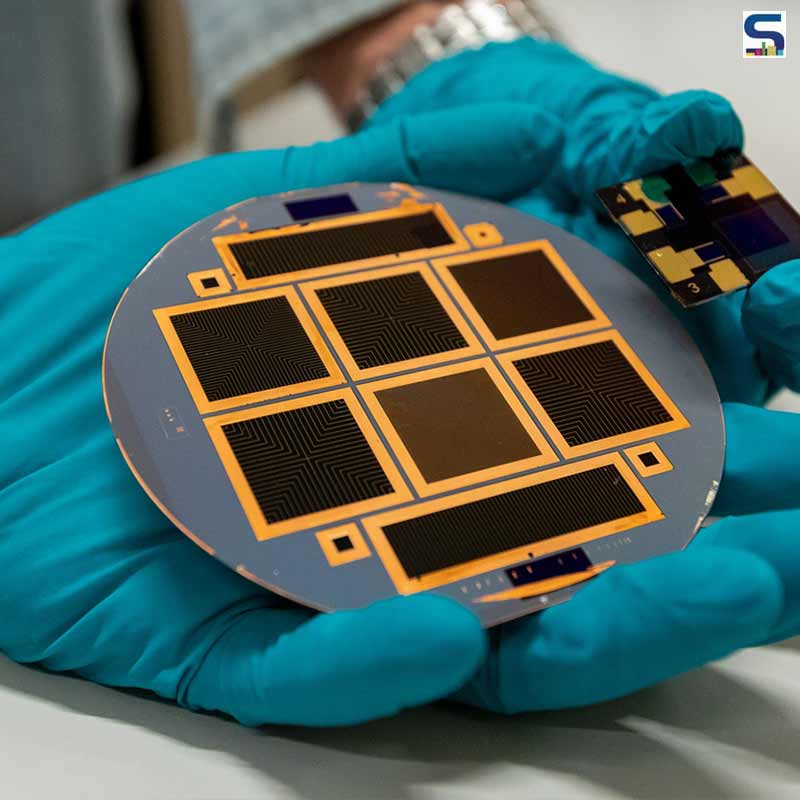

For the first time, researchers have developed a solar cell that can pass a 30 per cent efficiency barrier. Researchers at TNO, TU Eindhoven, imec and TU Delft, partners in Solliance collaboratively pushed the conversion efficiency of tandem solar cells beyond the limits of its current commercial photovoltaic (PV) modules. The high efficiency of the four-terminal perovskite/silicon tandem devices with a certified top cell pass barrier of 30 per cent has enabled more power per square meter and less cost per kWh. Here is a detailed report on SURFACES REPORTER (SR).

Hailed for its properties and its role in advancing solar technology, perovskite is touted as a miracle material. The traditional silicon-based solar cells offered an efficiency of nearly 22 per cent. However, with this new development, researchers claim that this achievement will be vital in reducing the usage of fossil fuels. According to Dr Mehrdad Najafi, Netherlands Organisation for Applied Scientific Research (TNO), “This type of solar cell features a highly transparent back contact that allows over 93 per cent of the near-infrared light to reach the bottom device. This performance was achieved by optimizing all layers of the semi-transparent perovskite solar cells using advanced optical and electrical simulations as a guide for the experimental work in the lab.”

Presented during the 8th World Conference on Photovoltaic Energy Conversion (WCPEC-8) in Milan, the team achieved the result by combining the emerging perovskite solar cell with conventional silicon solar cell technologies. Perovskite cell features transparent contacts. It is a part of the tandem stack that has been independently certified.

Upon achieving high-power density, it will create more opportunities to integrate the solar cell into construction elements, thereby allowing the existing surface area to be covered with PV modules. Hence, breaking the limit of 30 per cent is a big step in accelerating the energy transition and improving energy security by relying less on fossil fuels.

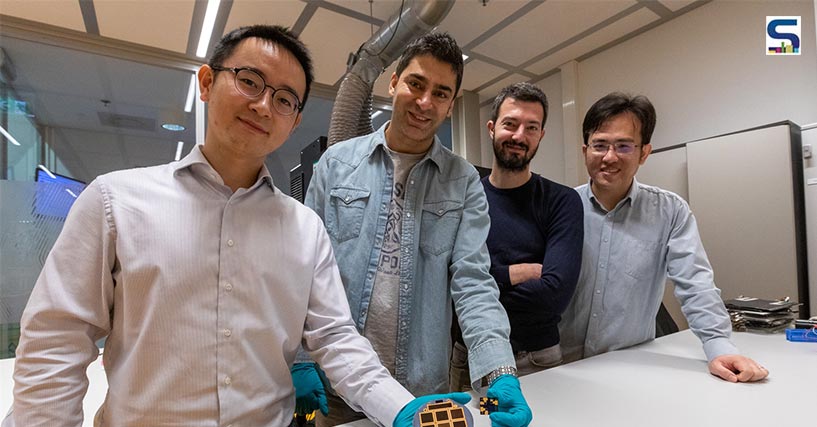

Image credits: Niels van Loon