A group of MIT engineers reportedly developed ultralight fabric solar cells that can quickly and easily turn any surface into a power source. According to Vladimir Bulovic, the Fariborz Maseeh Chair in Emerging Technology, leader of the Organic and Nanostructured Electronics Laboratory (ONE Lab), director of MIT.nano, and senior author of a new paper describing the work, “The metrics used to evaluate a new solar cell technology are typically limited to their power conversion efficiency and their cost in dollars-per-watt. The lightweight solar fabrics enable integrability, providing impetus for the current work.”

Alongside Bulovic, co-lead authors Mayuran Saravanapavanantham, an electrical engineering and computer science graduate student at MIT; and Jeremiah Mwaura, a research scientist in the MIT Research Laboratory of Electronics have worked on these cells and their research has been published in Small Methods. Here is a detailed report on SURFACES REPORTER (SR).

The lightweight solar fabrics enable integrability, providing impetus for the current work.

Properties

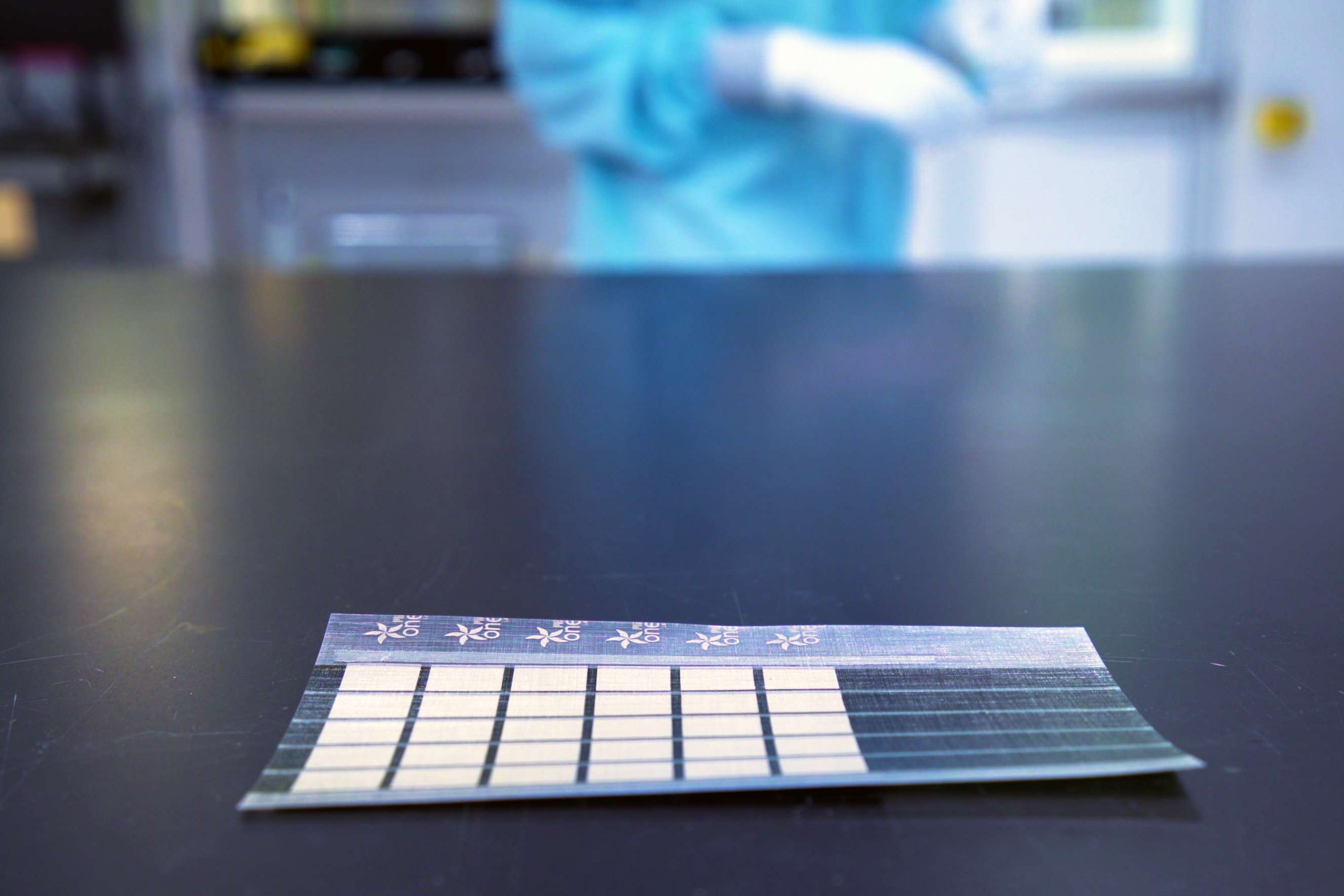

The ultralight solar cells are durable and flexible, and reportedly much thinner than human hair. According to the team, these solar cells are one-hundredth the weight of conventional solar panels, and generate nearly 18 times more power per kilogram.

Made from semi-conducting inks by using printing processes that can be further scaled up for larger manufacturing, these cells are glued together to a strong lightweight fabric, thereby making them easy to install on surfaces. These cells can provide energy on the go. They can be easily transported or deployed in remote locations as well for t assist in case of emergencies. Due to their thin and lightweight, the paper-like thin solar cells can be easily laminated on a variety of surfaces. The team informs, for instance, they can be installed onto the sails of a boat to provide power while at sea, on tents and tarps that are deployed during disaster recovery operations, or on the wings of drones to extend their flying range. Additionally, the cells can also be integrated into built environments with minimal installation needs.

The ultralight solar cells are durable and flexible, and reportedly much thinner than human hair.

Process

Traditional silicon solar cells are fragile. They are often encased in glass and put together in heavy, thick aluminium framing. Such a structure limits where and how they can be installed and deployed. A few years back, the ONE Lab team had developed solar cells using an emerging class of thin-film materials that were lightweight enough to sit on top of a soap bubble. However, these ultrathin solar cells were reportedly fabricated using complex, vacuum-based processes, which were expensive and challenging to manufacture. To overcome these two challenges, a printable ink-based material was developed.

These solar cells are one-hundredth the weight of conventional solar panels, and generate nearly 18 times more power per kilogram.

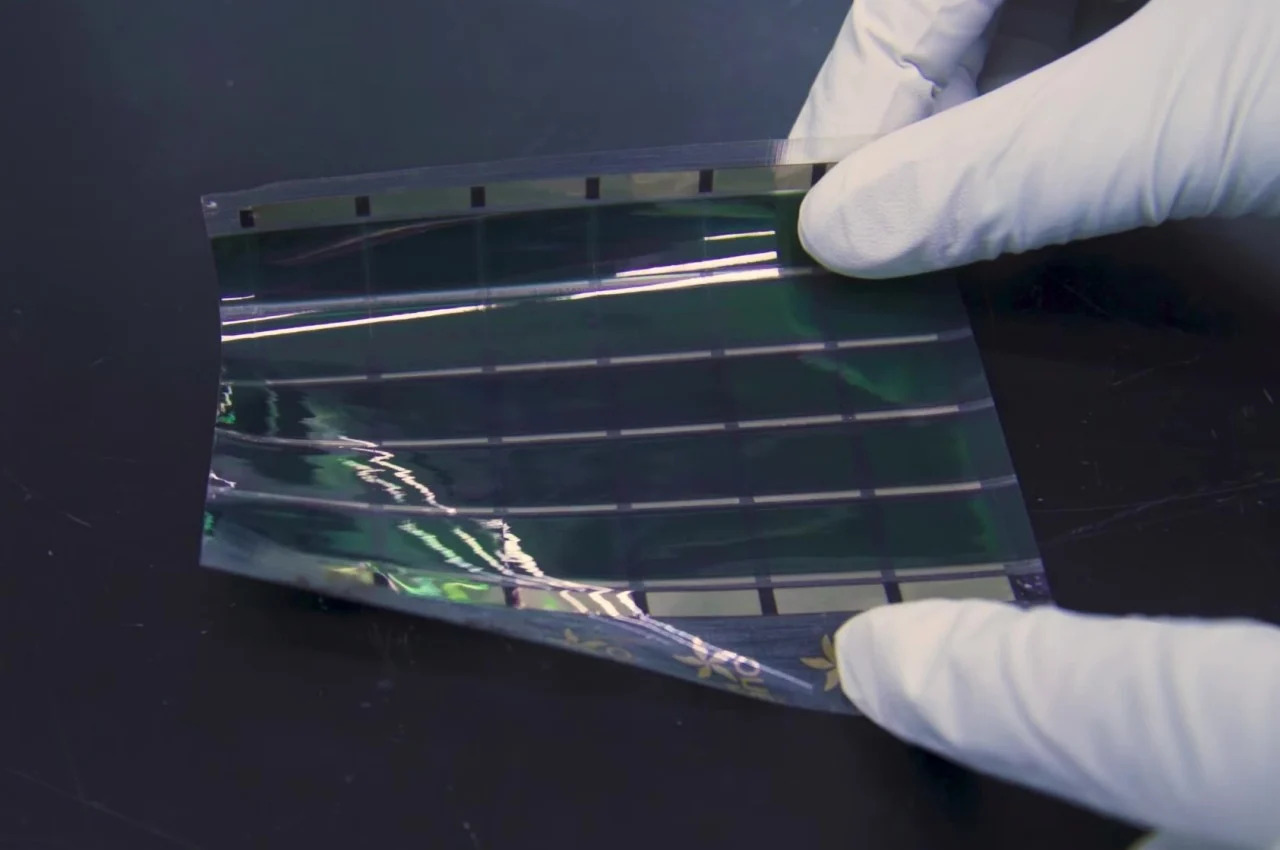

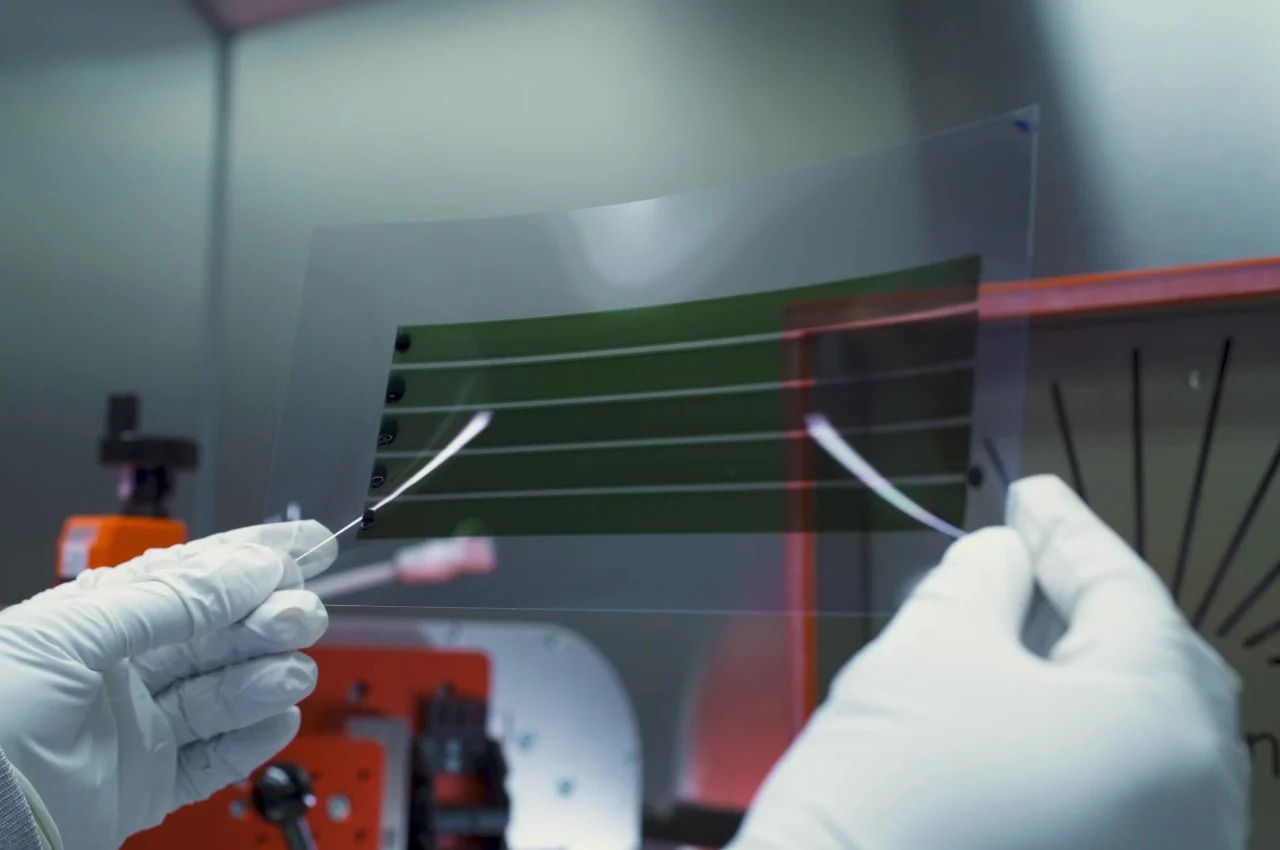

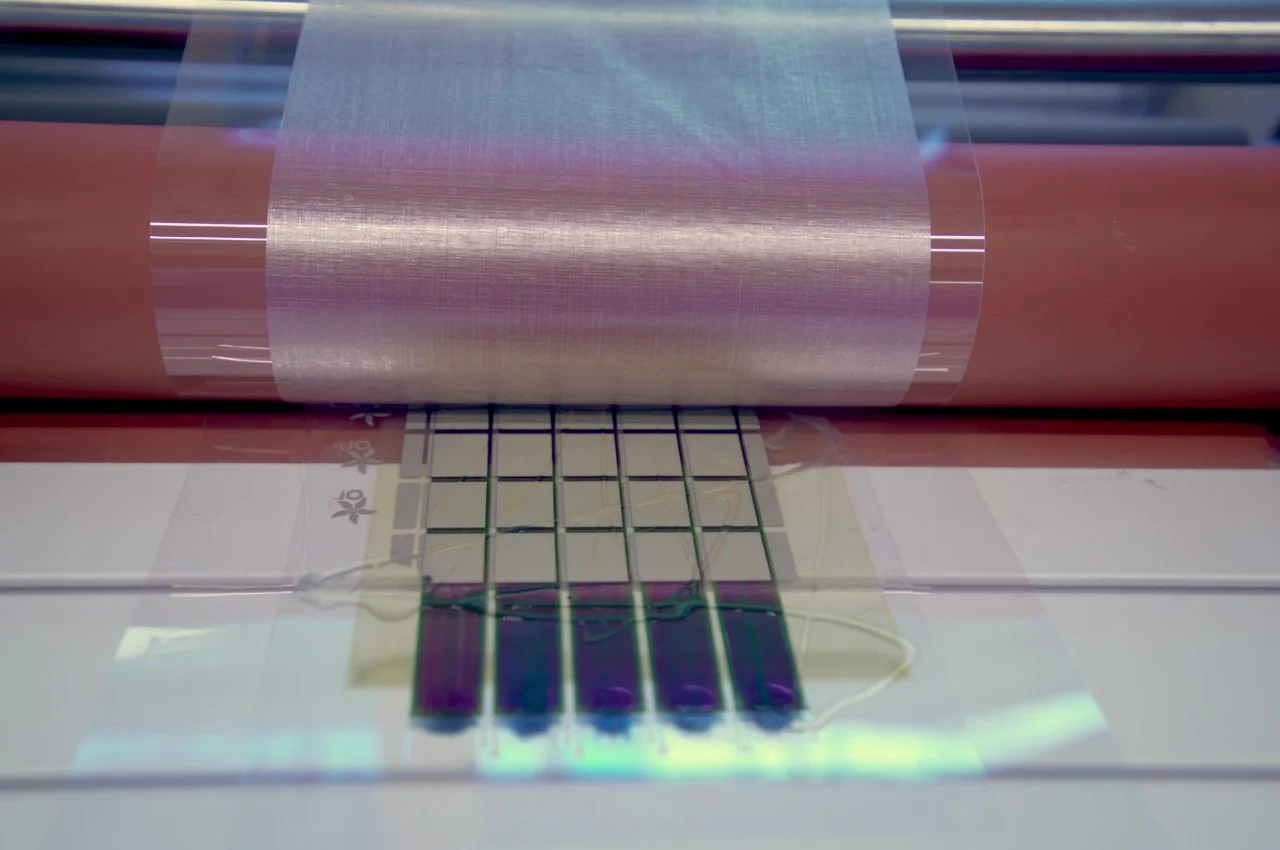

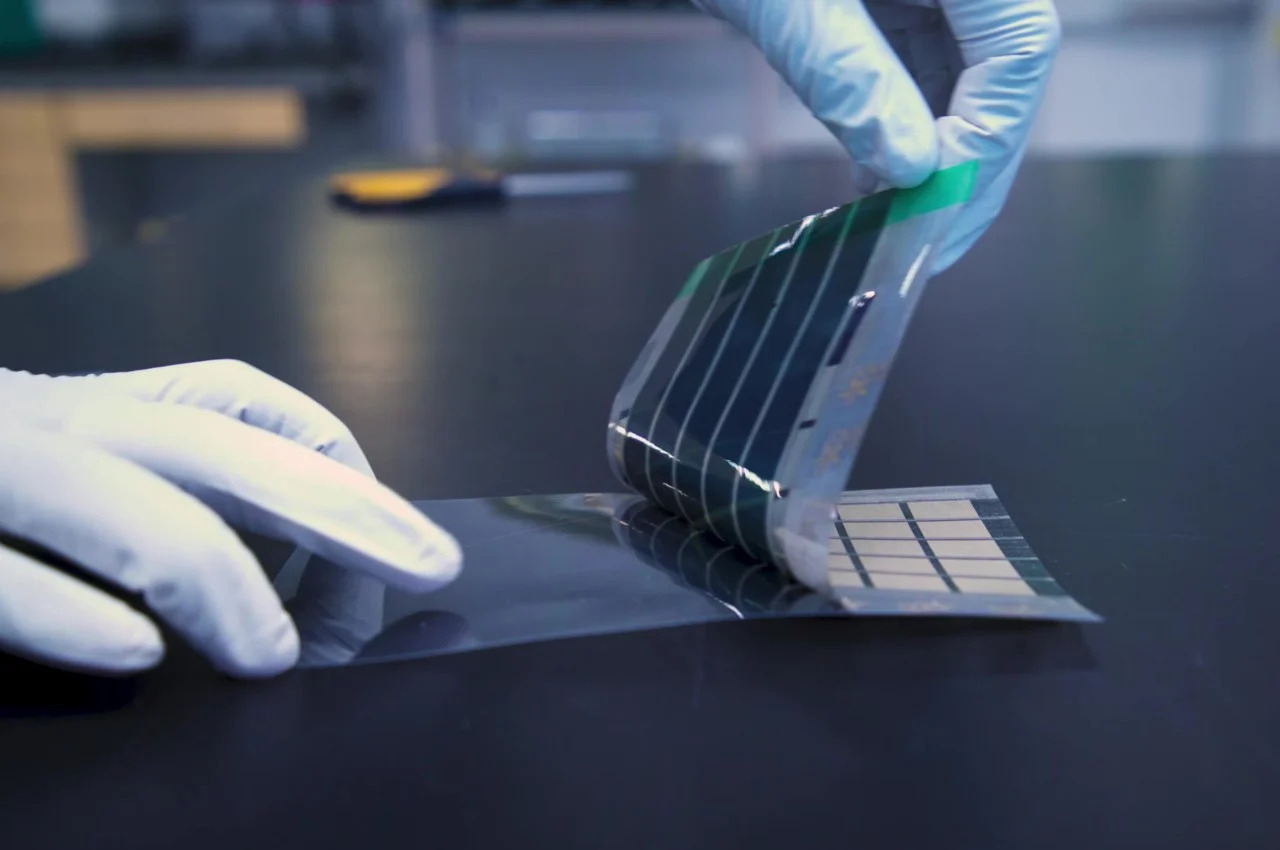

With the help of nanomaterials that are in the form of printable electronic inks, the team worked in the MIT.nano clean room where they coated the solar cell structure using a slot-die coater. This allowed the placing of layers of the electronic materials onto a prepared, releasable substrate that is only 3 microns thick. The use of screen printing allowed them to deposit an electrode on the structure to complete the solar module. The printed module, which is nearly 15 microns in thickness, is then peeled off by the researchers, off the plastic substrate, thereby forming an ultralight solar device.

They can be easily transported or deployed in remote locations as well for t assist in case of emergencies.

Overcoming challenges

That being said, such freestanding solar modules are often challenging to handle and can easily tear, thereby making them difficult to install and deploy. To overcome this, the MIT team researched a lightweight, flexible and high-strength substrate which would stay on the cells. For this, they identified fabrics as an optimal solution since they provide mechanical resilience and flexibility with little added weight.

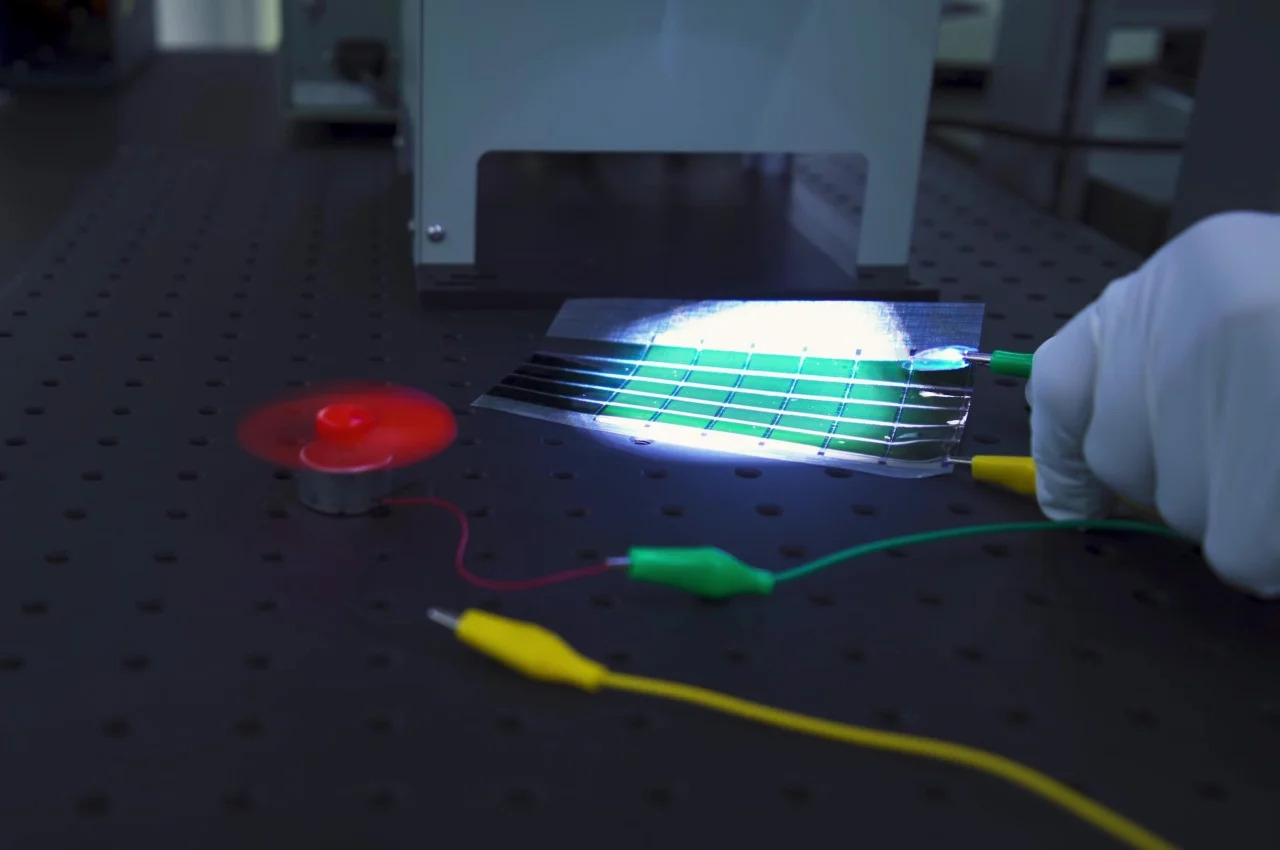

The researchers found that the solar cells can generate 730 watts of power per kilogram when freestanding and nearly 370 watts per kilogram if deployed on the high-strength Dyneema fabric.

The MIT team further found a Dyneema, a composite fabric that weighs only 13 grams per sqm. Made of fibers, this fabric is strong enough to lift sunken cruise ships such as Costa Concordia from the bottom of the Mediterranean Sea. The team added a layer of UV-curable glue to the fabric, which is merely a few microns thick, to hold the solar modules onto the fabric sheet, thereby making an ultra-light and mechanically robust solar structure.

These cells are glued together to a strong lightweight fabric, thereby making them easy to install on surfaces.

Upon testing, the researchers found that the solar cells can generate 730 watts of power per kilogram when freestanding and nearly 370 watts per kilogram if deployed on the high-strength Dyneema fabric, which is about 18 times more power per kilogram than conventional solar cells. They also tested the durability of their devices and noticed that despite rolling and unrolling a fabric solar panel more than 500 times, the cells still retained more than 90 per cent of their initial power generation capabilities.

Since these solar cells are lighter and much more flexible than traditional cells, they would reportedly need to be encased in another material to protect them from the environment. The team informs, the carbon-based organic material used to make the cells could be modified by interacting with moisture and oxygen in the air, which could deteriorate their performance. The team is, therefore, currently developing ultrathin packaging solutions that would only fractionally increase the weight of the present ultralight devices.

Image credit: MIT