Chinese scientists have crafted eco-friendly building materials inspired by the ingenious structures of sandcastle worms. These tiny marine creatures, found along the Californian coast, build honeycomb-like colonies by cementing sand grains together. Now, researchers from the Chinese Academy of Sciences have taken a cue from nature to create an alternative to traditional construction materials. Read complete report on SURFACES REPORTER (SR):

Published in the journal Matter on September 20, the researchers highlight the urgent need for low-carbon alternatives due to the significant environmental impact of conventional building materials. In 2021, materials like concrete, glass, steel, bricks, and aluminum contributed to approximately 9% of global energy-related carbon dioxide emissions, as reported by the UN-hosted Global Alliance for Buildings and Construction.

Why they turned to Sandcastle Worms?

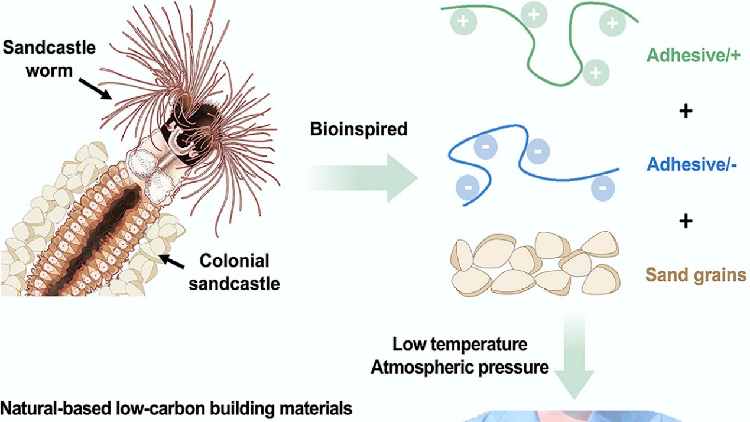

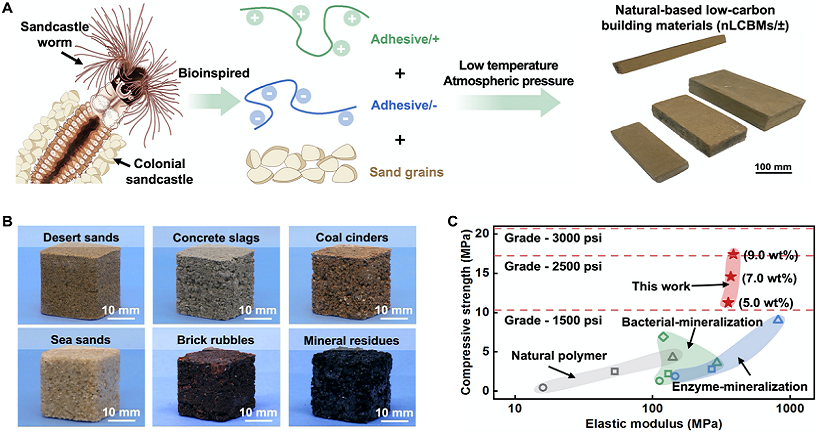

Facing the challenge of weak mechanical properties in natural alternatives to cement, the researchers turned to sandcastle worms. These marine creatures secrete an adhesive with positively and negatively charged proteins, creating a strong charge attraction. Mimicking this process, the Chinese team used oppositely charged bio-polymers to bind different grains for their innovative building materials.

Strength, Durability, and Versatility

Meeting the standard for structural compression, the materials developed by the team exhibit high resistance to breaking. They maintain mechanical performance under sun exposure, can be waterproofed, and are feasible for large-scale production. Importantly, these materials are versatile, capable of being made from negatively charged grains such as desert and sea sand, coal cinder, brick rubble, mineral residue, and concrete slag.

Sustainability and Recyclability

Amid a global shortage of specific sand types, the Chinese team's materials offer a sustainable solution. Not only are they versatile, but they also possess unique recyclability. The blocks can be remolded through crushing and hydrating in a five-step process, maintaining similar strength and elasticity to the original. Additionally, the production time is significantly shorter than traditional concrete, taking just two days instead of the standard 28.

Shaping a Greener Future

As the demand for building materials is set to soar, especially in developing economies, the researchers believe their natural alternative provides a promising path to accelerate the next-generation construction industry. With limited energy consumption and reduced carbon emissions, these worm-inspired materials offer a glimpse into a more sustainable and eco-friendly future.

Keep reading SURFACES REPORTER for more such articles and stories.

You may also like to read about:

Nescafe’s First Algorithmic 3D-Printed Biodegradable Store | Dolce Gusto Neo

An Artistic Farmhouse Amidst The Calm Natural Setting in Raipur Designed by Azure Interiors

and more...