Buildings have long been recognized as major contributors to global carbon emissions, with a significant portion of this impact stemming from the production of construction materials. Among them, cement is one of the most carbon-intensive, and traditional concrete manufacturing has become one of the largest sources of CO2 emissions worldwide. This poses a serious challenge for the future of our planet, especially as urbanization continues to expand. However, if we can shift towards building materials that not only avoid contributing to the problem but actively help solve it, we could unlock an extraordinary tool in the fight against climate change. Imagine homes, offices, and entire cities where the very walls around us don’t just provide shelter but also clean the air by capturing and storing carbon dioxide. Thanks to pioneering research at ETH Zurich, this vision is no longer science fiction but an emerging reality. Know more about it on SURFACES REPORTER (SR).

The Future of Sustainable Architecture

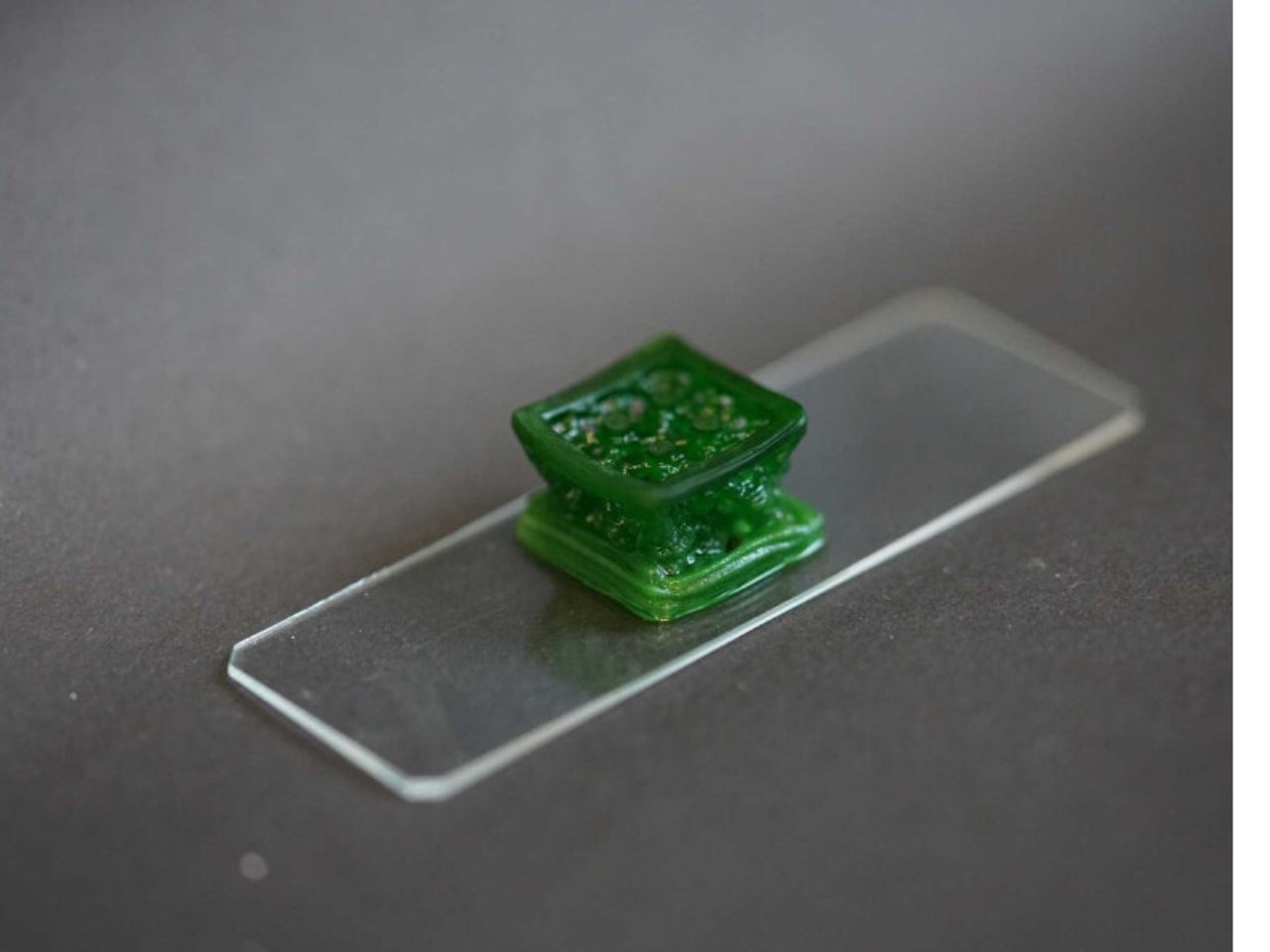

A team of scientists at the university has developed a revolutionary building material that goes beyond traditional notions of concrete. Unlike conventional cement-based products, which release massive amounts of CO2 during production, this new material does the opposite; it absorbs it. Even more astonishing, it does so because it is alive. The innovation lies in the integration of living bacteria directly into the material. These microorganisms are not ordinary bacteria; they are carefully selected for their ability to transform carbon dioxide into solid minerals.

Inside each block of this special concrete, millions of bacteria are at work, continuously pulling CO2 from the surrounding air. Once the bacteria capture the carbon dioxide, they use a nutrient mix, particularly calcium, to create calcium carbonate, the same mineral found in seashells and limestone. As a result, the material becomes stronger over time, while locking away carbon in a stable, solid form. The design of this living material is intentionally porous, filled with tiny holes that create an ideal environment for the bacteria to thrive. These pores allow air to flow through, ensuring a constant supply of carbon dioxide that the bacteria can transform. This clever design not only supports the life cycle of the microorganisms but also makes the carbon-capturing process highly efficient.

This clever design not only supports the life cycle of the microorganisms but also makes the carbon-capturing process highly efficient.

Benefits

The potential applications are immense, ranging from walls and floors to outdoor structures. The benefits extend beyond carbon capture. Compared to conventional concrete production, creating this living material requires far less energy, making it more sustainable from the outset. The bacteria themselves are low-maintenance. They need only a simple nutrient supply and basic conditions to remain active. Remarkably, the material even demonstrates a form of self-healing. If cracks or small damages occur, the bacteria produce additional calcium carbonate, naturally repairing the structure much like human skin heals after a cut. This property could significantly extend the lifespan of buildings, reducing the need for costly repairs and lowering the long-term environmental impact of construction.

The research is reportedly still in development. The ETH Zurich team is now focusing on ensuring that the material is strong enough for widespread architectural use and exploring ways to scale up production. Questions remain about how the bacteria will behave over decades, particularly under varying environmental conditions such as extreme heat, cold or humidity.

Image credit: ETH Zurich