Mass Timber Architecture is an emerging trend from low-to-mid rise building construction in different parts of the world today. The driving force behind using timber as a construction material is the realization that two of our most primary building materials – steel and concrete– have a massive carbon footprint. Both of these materials are energy consuming and have a huge environmental impact. Concrete and steel alone responsible for 4-8% of CO2 emissions globally. Therefore, a new generation of architects and engineers are pioneering a distinctive approach to building materials- the revival of wood. In this article, we, at SURFACES REPORTER (SR), will assess the benefits of mass timber architecture, its prefabrication, various other engineered woods while also debunking the misconceptions associated with it. Take a look:

Also Read: Latest Material Trend The Wood in Architecture and Interiors

While concrete and steel are still widely used for building construction, Mass timber buildings are on an upswing worldwide because of their renewable and sustainable features.

Robina Town Center, Australia

Robina Town Center, Australia

Although India is in the early stages of a mass-timber construction boom, its adoption in a range of commercial real estate projects is showing an upward trend. The most common wood material which is gaining popularity these days in architectural projects is the use of bamboo owing to its strength, durability and competitive cost. Not only globally but in India also, Timber and its various composites have been used as structural elements.

Also Read: 10 Beautiful Architecture and Design Projects in Bamboo | Surfaces Reporter

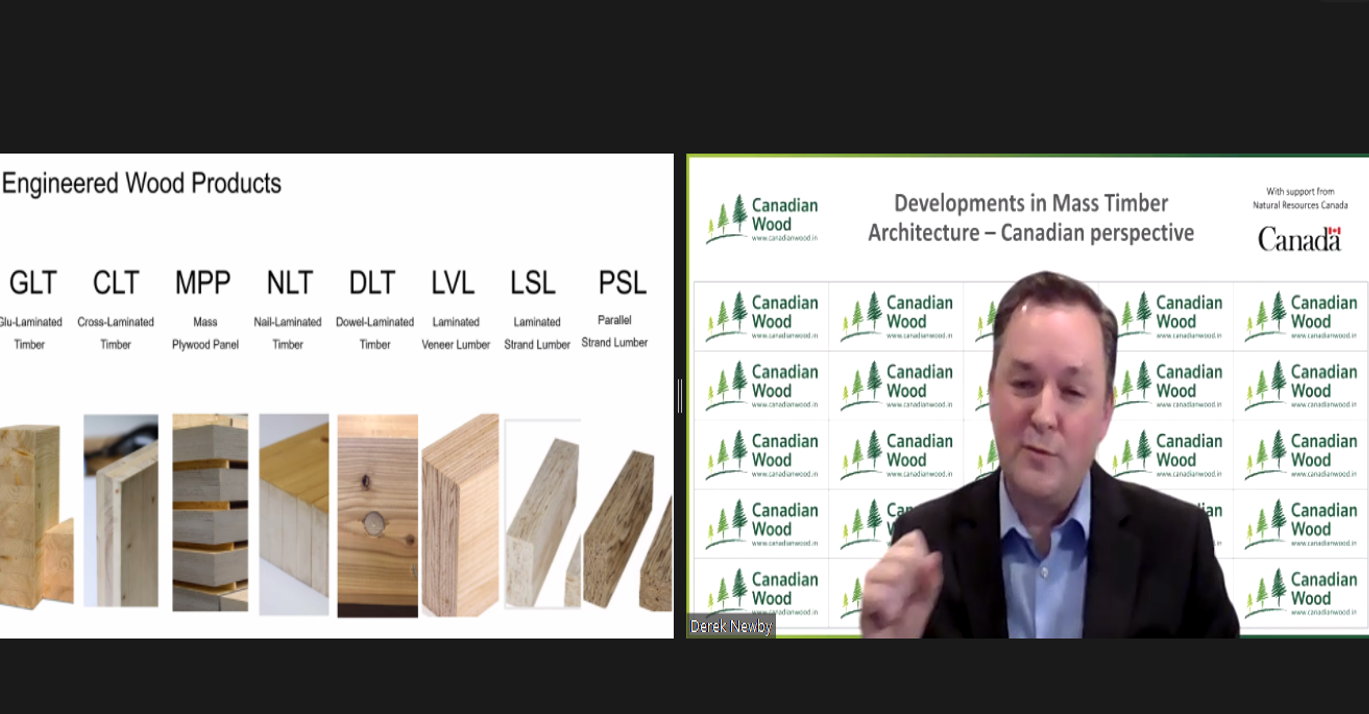

Various Engineered Products Used in Mass Timber Structures

There are available several Wood engineered products that are used in mass timber structures produced from the same hardwoods and softwoods used for lumber and created by mixing ground wood particles with heated thermoplastic resin. Cross-laminated timber, glue-laminated timber, mass plywood panel, nail laminated timber, dowel laminated timber are a few of the engineered wood products. Canadian architect and industry stalwart Derek Newby gave an in-depth introduction to various engineered products on the recent webinar conducted by Forestry Innovation Consulting India Pvt. Ltd. (FII, India) also known as Canadian Wood, focused upon ‘Developments in mass timber architecture – Canadian perspective’.

Some manufactureres use both virgin and recycled thermoplastics in the wood composites construction, with polyethylene-based products the most common. While others also add colorants, coupling agents, UV stabilizers, and lubricants to make it specifically for a particular application. Timber composites are used in both home and industrial construction and are often used as a substitute for beams and joints in building projects.

Outdoor deck flooring- wood and composite

Outdoor deck flooring- wood and composite

Timber composites are good for benches, fencing, railings, cladding, outdoor deck flooring, landscaping, and other works. Plywood is considered the common and widely used composite wood material, created from sheets of cross-laminated veneer. It is used in a variety of architecture projects. Fibreboard, Oriented strand board, Laminated timber, cross-laminated timber are different types of composite products used in the construction process.

Also Read: Plywood Lines Every Surface of Shen’s New Beauty Store in Brooklyn | Mythology

Benefits of Building Mass Timber Structures

Buildings designed out of mass timber have various benefits. The mass timber structures are eco-friendly, able to reduce emissions, allow a fast-paced building process, saves time, money, and last but not least look visually attractive.

Other benefits:

Eco-friendly: One of the major benefits of timber structures is that wood is an environmentally-friendly material. And wood is the only carbon-neutral construction material that absorbs the atmospheric carbon dioxide in it. It is a sustainable and renewable resource.

Prime Insulator: The wood is a fantastic insulator. Where steel buildings weaken or collapse due to their nature to expand on heating, wood reacts opposite to this. When heated, the wood dries and becomes harder. So, no more energy leakage from the home while cooling or heating your wooden home.

Thompsom River University, Kamloops, Canada

Thompsom River University, Kamloops, Canada

Fast to Build and Cost-saving: It takes less time to construct a wooden building than those made of other materials. That means it will save time as well as money. Some developers can build a wooden house on-site in less than a week. And any type of weather conditions- rain, ice, snow- would not hamper the construction process.

Wooden Structure Looks Attractive: The mass timber buildings are aesthetically appealing as well as more sustainable. Therefore, these are getting more attention from both building developers and governments. There are available more than 5000 different types of engineered products to choose from. Some woods have special textures, grains, colours, or appearances, while others are good for acoustics or insulation.

Prefabrication of Timber Buildings

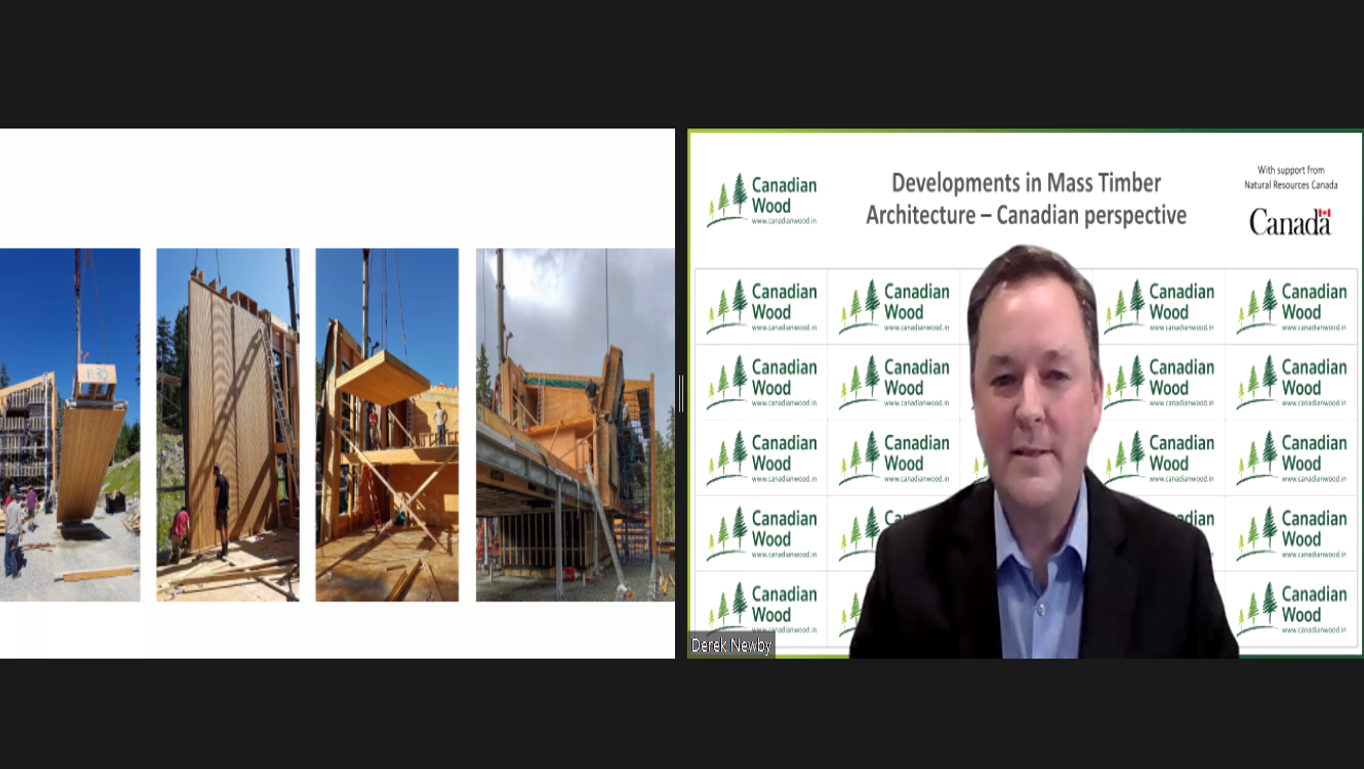

Prefabrication and modular techniques can help optimize the process of mass timber construction projects.

According to Derek, “Construction for mass timber projects is more a process of assembly on-site as parts are delivered in a highly prefabricated condition. Prefabrication saves time, sites are cleaner and less labour is required. Sometimes foundations are reduced because the material is lighter. All this is possible with detailed preparation and construction knowledge of those in the industry.” Derek also presented the architectural case studies and projects in mass timber from Canada.

Embracing digital tools for instance 3D modeling, computer numeric control (CNC) machines, and building information modeling (BIM) making the prefabrication and communication amongst the architects and building developers easier and faster. The use of modeling technologies also allows the construction of the building with precision and with reduced waste. No waste both on-and off-site diminishes the ecological impact of a project, as the specifications of components are decided in advance. So, this also adds to the sustainable nature of prefabrication.

Also Read: 7 Popular 3D Modelling Software in Architecture | Surfaces Reporter

Common Misconceptions Related To Building With Wood

There are some myths about the buildings made of wood. Have a look:

Deforestation of Natural Forests- This is a genuine and the most common notion amongst people that how wooden structures can be environmentally sustainable if you are cutting trees to manufacture buildings- it may lead to deforestation. Dr. Brand Wessels, chairperson of the Department of Forest and Wood Science at the University of Stellenbosch says that “There is a distinct difference between harvesting timber from sustainable and well-managed plantations and the deforestation and degradation of natural forests that should be protected.” There are responsibly managed plantations to grow timber in a controlled environment rather than cutting natural forests for it.

Higher Cost- Peter Bradfield - Technical Advisor at Canadian Wood said during their webinar on Mass Timber Architecture, “There is a perception of higher cost, and while this may be true at times, the reality is when we optimize the design and account for the benefits, including rapid build time, wood as an option is often more competitive than it is understood to be.’ So, indeed, the construction cost of wooden houses is relatively more than those built from other materials, but it is nothing compared to the benefits wood offers.

Clemson University, Cooper Carry, South Carolina

Clemson University, Cooper Carry, South Carolina

Strength and Durability- the other misconception is about the durability and strength of the wood structure. Perhaps there was a time when timber houses were not that durable but now things have changed. Modem and highly advanced technologies make it possible to create wooden structures that can stand for centuries. You can comprehend the durability of mass-timber structures with the rapid timber-constructions happening worldwide.

Mjøstårnet, Norway

Mjøstårnet, Norway

Voll Arkitekter designed Mjøstårnet, which is the tallest mass timber building in the world. This 18-story (280 feet tall) mixed-use building was designed in 2018 in Norway. It is anticipated to be surpassed by Ascent- a 284-ft-tall hybrid timber-and-concrete building underway in Milwaukee. The architecture work of this building, designed by LEVER Architecture- is scheduled to be finished by the summer of 2022. So, with these constructions, one cannot doubt the durability and strength of wooden structures.

Read more about Mjøstårnet here: Norway Constructs the Worlds Tallest All-Timber Building

Also, Bogdan Newman Caranci (BNC) has designed a new mass timber office building- 77 Wade Avenue- in Canada that will become the City’s tallest. Developed by Next Property Group, the project is sprawled over an area of 150,000 square feet across 8 floors.

BNC's Mass Timber Office, Canada

BNC's Mass Timber Office, Canada

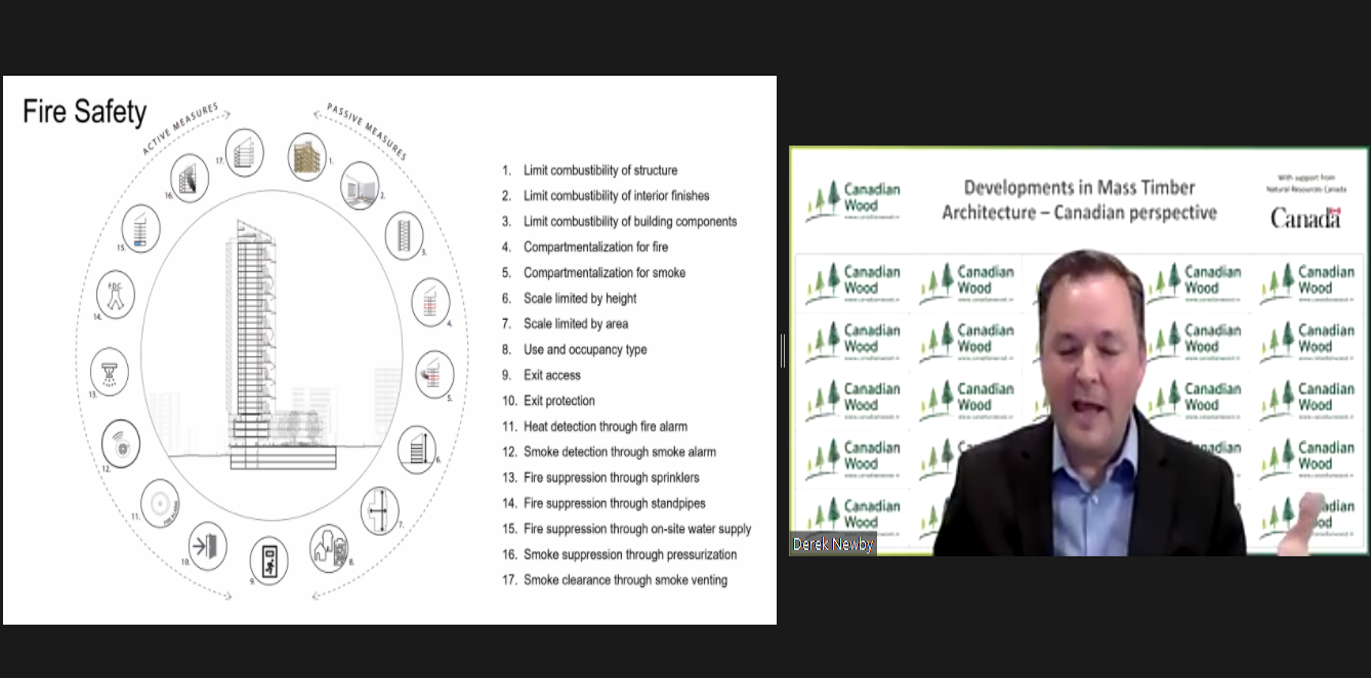

Fire Hazard- The most common misconception that prevents the construction of timber houses is low fire safety. Though it had been a point of concern earlier, but these days manufacturers are producing engineered woods that can be processed in some special chemical compounds- flame retardants- to avoid potential dangers. These compounds not only protect the house from fire but also generate foam to dowse when the fire started.

In the webinar, Derek also stressed on the fire safety as first priority in mass timber architecture. He talked about some active and passive measures that should be taken while construciton.

He also talked about various other misconceptions related to various aspects of building with wood such as seismic performance, insect/mould/moisture and acoustics during the webinar. You can check out the whole webinar at Canadian Wood India Youtube Page.

Nonetheless, Informal wooden structures that are not built as per determined codes and, are surrounded by other potential fire hazards are definitely considered a threat to human life and unsuitable for habitation. So, don’t believe blindly in all the rumors about the qualities of the timber structures. These misconceptions prevent both the consumer and the companies to harness its manifold benefits. So, it is wise to select a trustworthy company with professional workers for building a timber house.

Also, in the light of accelerated climate change, it has become imperative for us to lay to rest these common myths about wooden buildings and leverage the ecological benefits of wood such as oxygen production, carbon seizure, natural room ventilation, low-cost, faster construction, low transport emissions, and much-reduced HVAC burden.

*Note: The quotes in the article are picked from the Canadian Wood Webinar on Mass Timber Architecture

Image courtesies: Canadian Wood and Architect Derek Newby

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

This Tiny Prefab Home, Made From Cross-Laminated Timber, Unfolds in 3 Hours | Brette Haus

Why is it Vital to Upgrade HVAC System?

Hardwood Cross Laminated Timber - An Inspiration for Architects

Each Lumber Tile in the London Timber Pavilion is Cut, Laminated And Air-Pressed By Hand | Schiller Projects

and more...