Bruce Shapiro, the motion control artist, science educator, the father of Eggbot and the Co-Founder of Sisyphus Industries LLC, has dedicated 25 years to exploring motion control as a medium for artistic expression. He uses a steel ball and a layer of sand along with CNC technology to transform the average home tables into kinetic art pieces that double as a coffee table or side table. His first-of-its-kind computer-controlled kinetic Sisyphus Tables are permanent installations in museums in the US, Canada, Germany, Poland, Australia, and Switzerland. The artist has brought this innovative and captivating product out of the museum to the people’s homes and offices as he wanted more people to get to know it, spend their time and energy composing it. Being a lover of art, technology, and furniture design, SURFACES REPORTER (SR) is intrigued by this mesmerizing product and hence presenting here how the Sisyphus Industries- make such unusual tables and how these tables work. Take a look:

Also Read: A Lake in the Middle of the Gorgeous Table by Marco Sousa

How Sisyphus Table Works?

Shapiro uses Sisbot that rolls a ball silently through sand, slowly creating unending beautiful patterns.

Sisyphus is not only a kinetic artwork but is also an instrument, which functions through a Wi-Fi-connected robot and controlled by a small Raspberry Pi computer and mobile app.

The app has “tracks” that play any of more than 160 unique design patterns, much like the songs played in a music player. Each Sisyphus table allows the user to curate and creates its custom designs.

Time Lapse Video of Sand Art Formation on Sisyphus Table

The Formation of Sisyphus Table- From Production to Delivery

To ensure Sisbot works efficiently and effectively, each Sisyphus table undergoes rigorous testing post-assembly.

Soon after this process, hand-finished and CNC-machined hardwood veneers- either cherry or walnut- are sprayed with lacquer. It is then dried up before applying to the table.

These hardwood veneer rings are hand-sprayed individually with lacquer. This entire process of spraying and coating takes around half an hour.

Subsequently, the rings are then moved to a drying rack where they will set for one whole day so that they get fully dried.

Next in the process comes welding of steel metal frames before the powder coating. Soon after the assembly of steel metal table frames, the base of the table has been assembled.

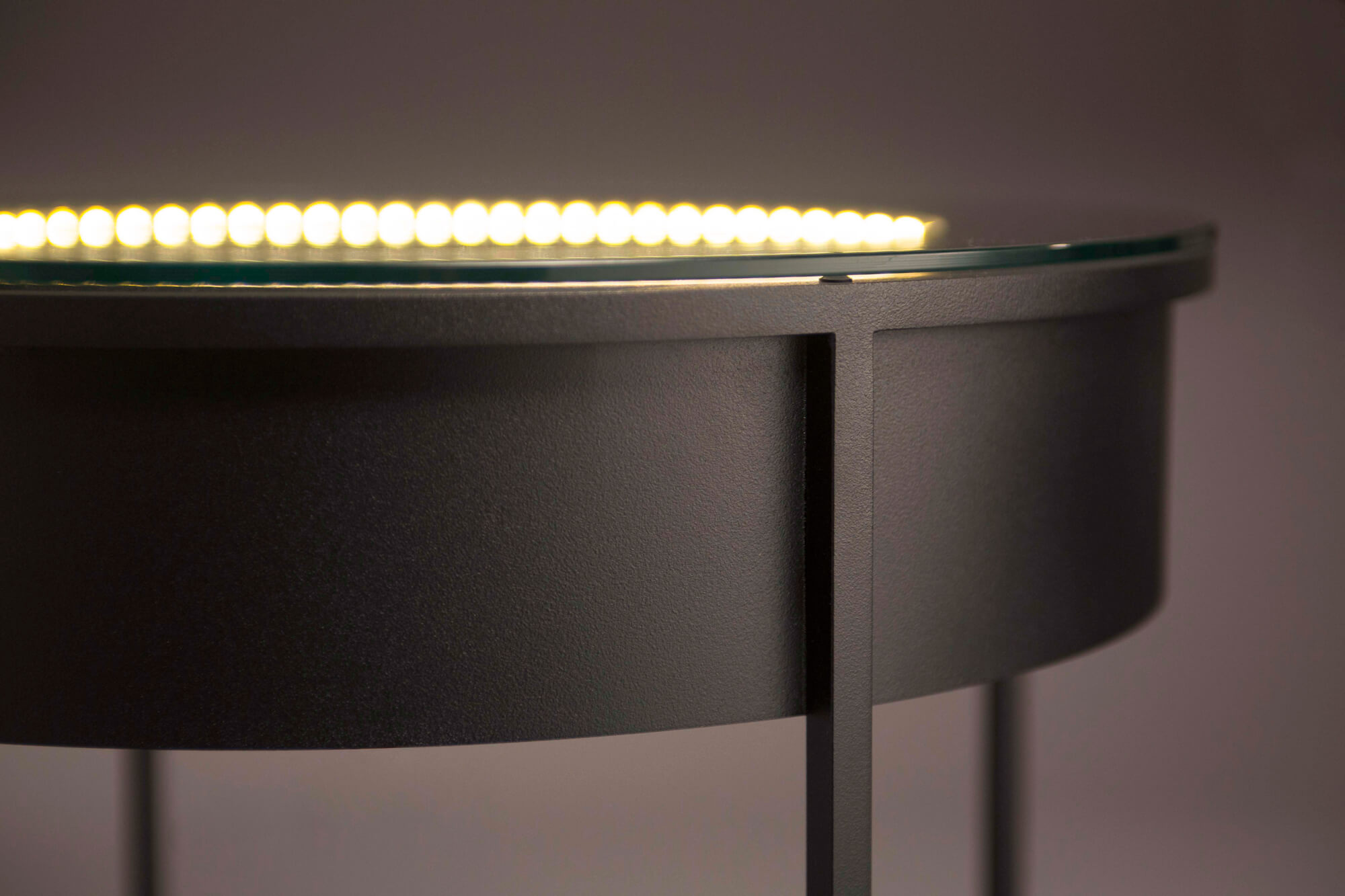

Then, the fully assembled Sisbot is added to each metal table frame. Afterward, Software-dimmable white LED lighting is installed to encircle the sand field. 12 Volt universal Power supplies have been given to both the LED lighting and Sisbot.

At this step, the Sisbot is tested 24/7 to ensure its long-lasting performance. So, the process is finished and the Sisyphus Table is finally ready to be boxed and get delivered to the shop.

The final step includes pouring fine, white silica sand into the Sisyphus table’s main medium, and tempered glass is added to its top.

It can be done by the owner of the kinetic art table. And advanced-art is simple enough for just about anyone to create in a matter of minutes.

You just need to get the free app from the Google Play store or iTunes store and plug in the table and connect it to the app.

Info and Image Courtesy: Sisyphus Industries

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

You may also like to read about:

Twisted Table by Radhwa Kabli

Table that ensures work and health together

Charleston Chair: An Epitome of Elegant Creation yet Comfortable Experience

T-Shaped Wooden Detail Adorns the Top of Turri New Coffee Tables of Blues Collection | Giuseppe Viganò | Studio Viganò

and more...