While pursuing his master’s in product design at the Royal College of Art, London, Erik de Laurens invented Scalite – a sustainable building product that is made out of fish scales. Fish scales are easily discarded by food and aquaculture industries as they aren’t edible. To mitigate these thrown-out scales that add to the growing amount of waste, Erik de Laurens realised the potential of these useless scales that have certain components that make them hard as stone and beautiful as marble. Know more about his work on SURFACES REPORTER (SR).

Scalite is a sustainable building product that is made out of fish scales.

Scale by scale

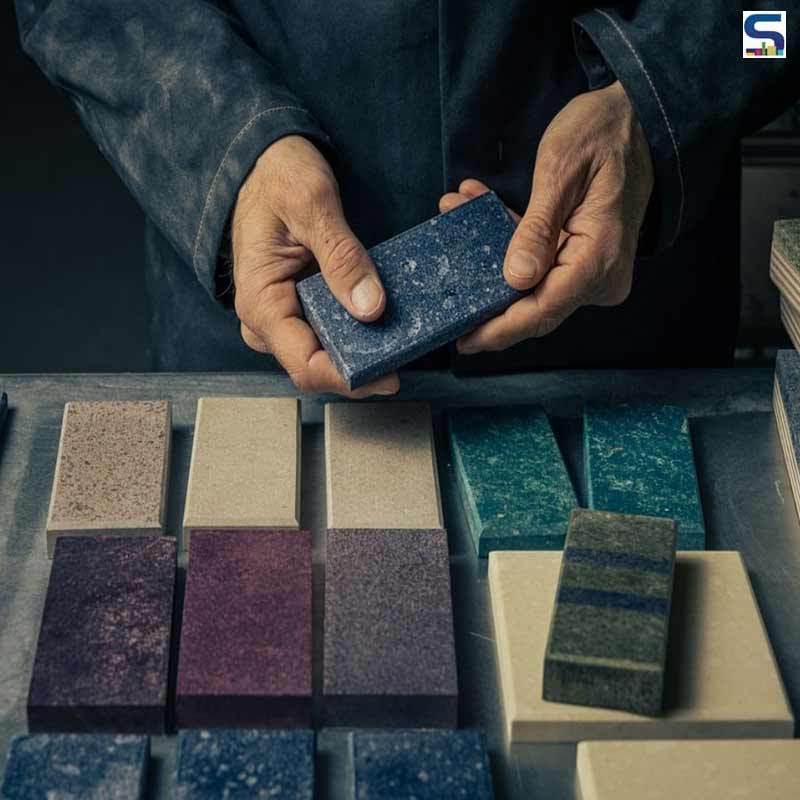

Erik de Laurens felt the urge to propose a new production system where non-deleterious materials would be locally and sustainably produced. Upon tapping agribusiness, he identified fish scales as a promising raw material. A waste of the fishing industry, fish scales are available in large quantities and have no value. After several researches, Erik de Laurens invented a stone-like material that is 100 per cent made out of fish scales. Named Scalite, he induced the material to replace plastic by making goggles, beakers and a table to demonstrate and communicate its importance.

Erik de Laurens invented a stone-like material that is 100 per cent made out of fish scales.

Later in 2017, he presented the project to his cousin Edouard de Dreuzy and by the next year, the two cousins established an ocean-friendly brand Scale that aims at producing and developing ocean-friendly materials.

The team collects scales from sustainably managed stocks of tilapia that are further processed into Scalite.

What is Scalite?

Made entirely from fish scales, Scalite is a renewable byproduct of the fishing and aquaculture industries. The team collects scales from sustainably managed stocks of tilapia that are further processed into Scalite. Irrespective of the fish species, scales contain a mineral phase called hydroxyapatit and an organic phase named collagen. However, the rate of these phases may differ depending on the species.

Scalite uses a natural biopolymer that is contained within the scales.

Scalite uses a natural biopolymer that is contained within the scales. During its process, this biopolymer is extracted and mixed with the mineral part of the scales to create the raw material. The powder is compressed into their proprietary process to form sheets of various dimensions. Designed as a natural material, Scalite is free from deleterious resin, plastic or artificial glue, thereby making it chemical-free.

Designed as a natural material, Scalite is free from deleterious resin, plastic or artificial glue, thereby making it chemical-free.

Properties

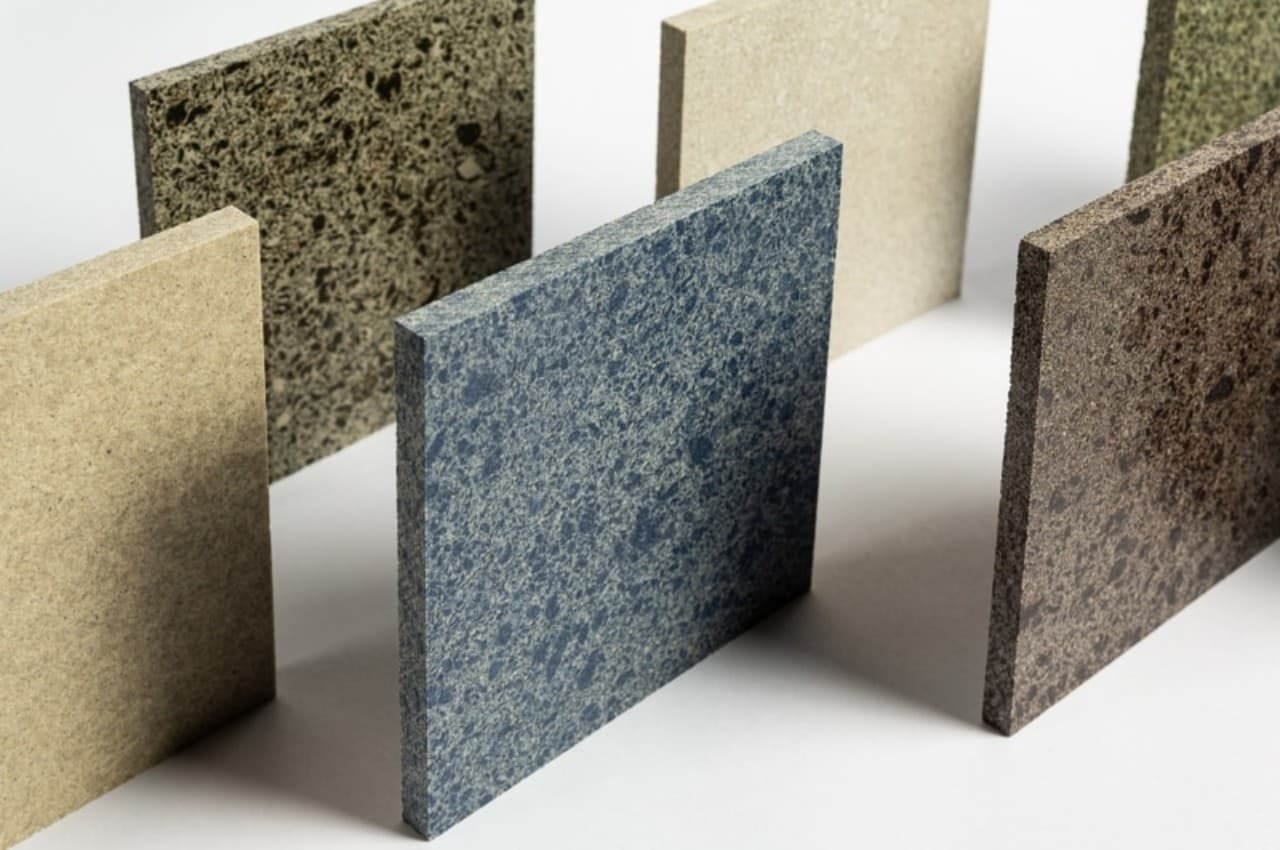

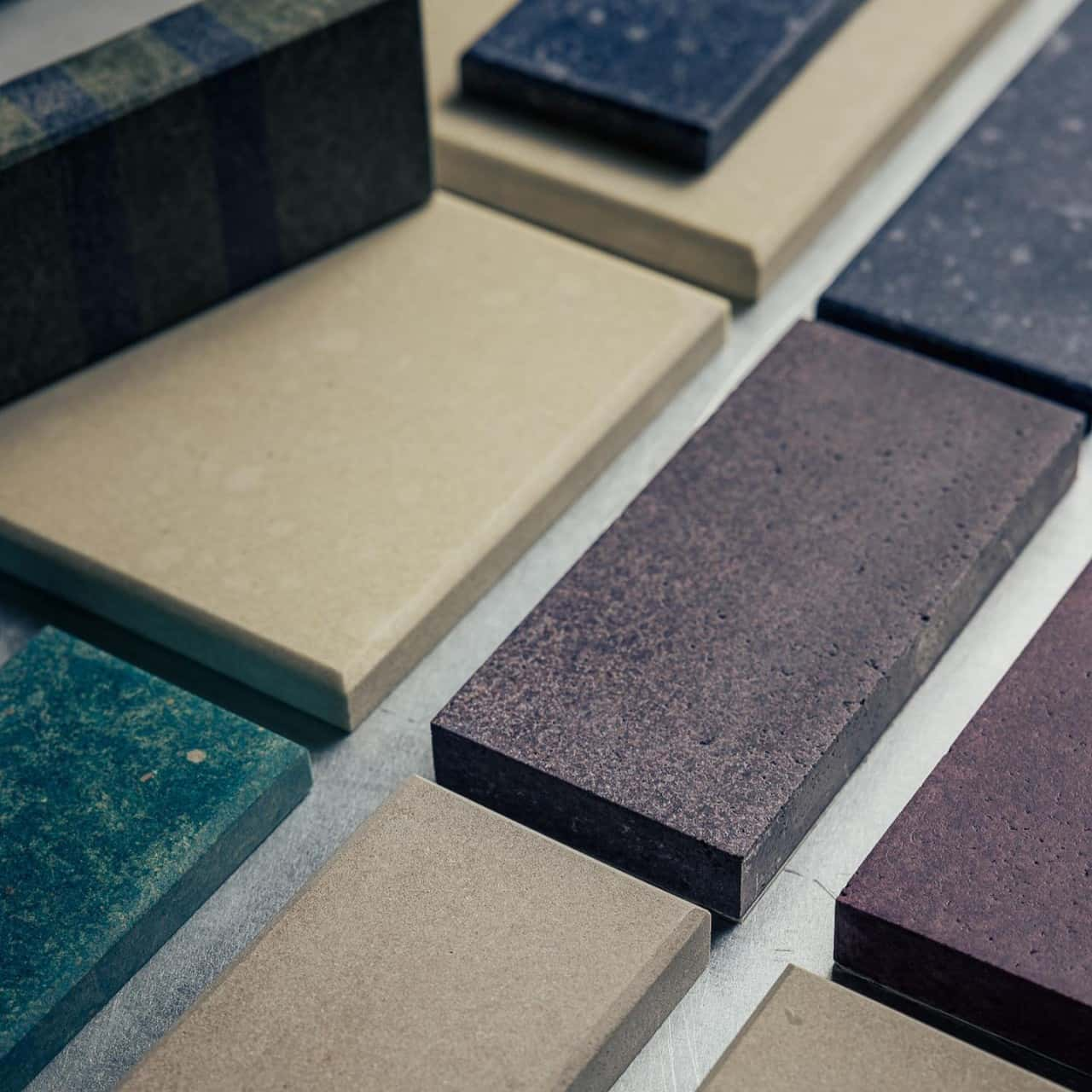

Scalite comes in a standard dimension of 550mm X 550mm with 12mm thickness, and is recognizable to its marble aspect in six standard colours and one natural colour. A Scalite tile has a stone-like pattern and is well suited for interior application. The tiles come as ready to be assembled. They are resistant to fire and scratches, can be easily repaired, are COV and formaldehyde-free, Msc certified and have a low carbon footprint. The material is bio-sourced, 100 per cent recyclable, biodegradable and requires light maintenance.

Scalite comes in a standard dimension of 550mm X 550mm with 12mm thickness, and is recognizable to its marble aspect in six standard colours and one natural colour.

Additionally, Scalite can be transformed with conventional timber tools such as circular saws, band saws, drills, spindles, CNC machining, sanding, etc. Jointing with a nearly invisible joint can also be achieved with conventional timber adhesive. Screws and inserts can be used with pre-drilling.

The material is bio-sourced, 100 per cent recyclable, biodegradable and requires light maintenance.

Mechanical properties

Mohs hardness: NF EN 167713

Tensile strength: ISO 527: 15.6 MPa

Young module in traction: ISO 527: 3 775 MPa

Resistance to compression: ISO 604: 71 MPa

Flexural strength: ISO 178: 31.3 MPa

Image credits: Scale