Architect and furniture designer Guillermo Cameron Mac Lean’s architectural take on shelving through his modular furniture system Liston allows users to create infinite configurations. Similar to building blocks, Liston allows users to assemble and create a structure that comprises wooden slats and bright yellow cable ties.

Top: Liston allows users to create infinite configurations; Above: The modular furniture system is made out of two types of structural wooden slats of 1 and 2 modular lengths.

Top: Liston allows users to create infinite configurations; Above: The modular furniture system is made out of two types of structural wooden slats of 1 and 2 modular lengths.

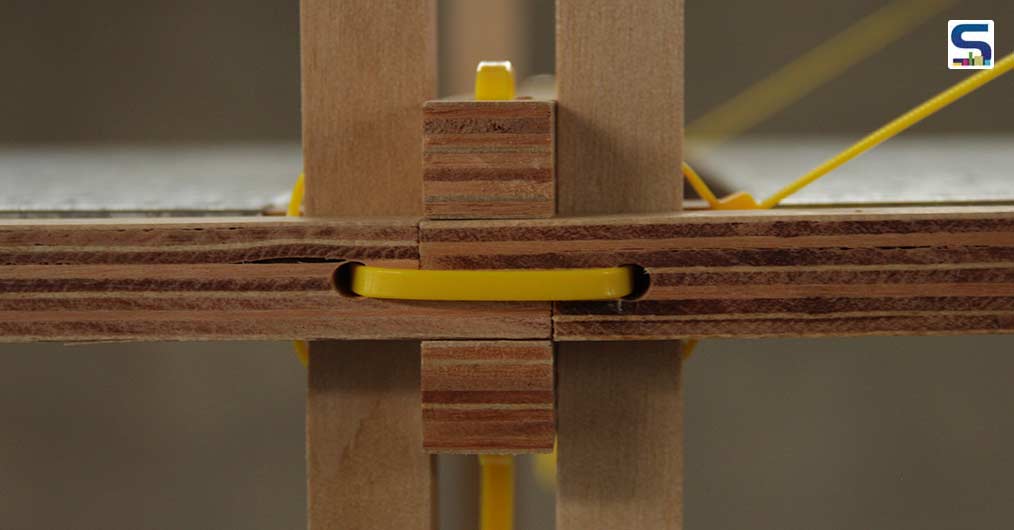

Made out of two types of structural wooden slats of 1 and 2 modular lengths, Liston possesses the ability to change, reduce and expand as per the users’ requirements. It combines in all directions and can be assembled by means of reusable seals (RTA) by obtaining any type of furniture given by cubes of 40 x 40 x 40 cm.

This method of construction also reduces the packing box needed for the item by 18 times in comparison to other flatpack furniture.

This method of construction also reduces the packing box needed for the item by 18 times in comparison to other flatpack furniture.

According to Mac Lean, “Separating the structure results in greater structural capacity, an ethereal, light piece of furniture is perceived, subtle so that the user does not get tired of it and has the need to replace it. This isn’t a good habit. This feature also contributes to the fact that what is important is not the piece of furniture but what it contains.”

The system can easily adapt spatially to different spatial needs, thereby becoming a spatial organizer.

The system can easily adapt spatially to different spatial needs, thereby becoming a spatial organizer.

The system can easily adapt spatially to different spatial needs, thereby becoming a spatial organizer, if used as a division panel, among other things. Mac Lean’s Liston owns the method of construction as pixels that can grow in any direction, adapting to different spaces as needed. Additionally, on account of its nature of production, each of its parts is repairable and can be replaced, which means there is no need to discard any element in case of partial damage. They are sold separately as well. No type of glue is used in the making. The joints use a reusable seal, which can be taken on and off by pressing a button. In this way, it can be easily separated by material for later recycling.

Each of its parts is repairable and can be replaced, which means there is no need to discard any element in case of partial damage.

Each of its parts is repairable and can be replaced, which means there is no need to discard any element in case of partial damage.

This method of construction also reduces the packing box needed for the item by 18 times in comparison to other flatpack furniture, saving on transportation costs by consuming less storage and resources. The reusable seals that are used for its assembly are found in hardware stores and are available in many colours.

Image credits: Guillermo Cameron Mac Lean