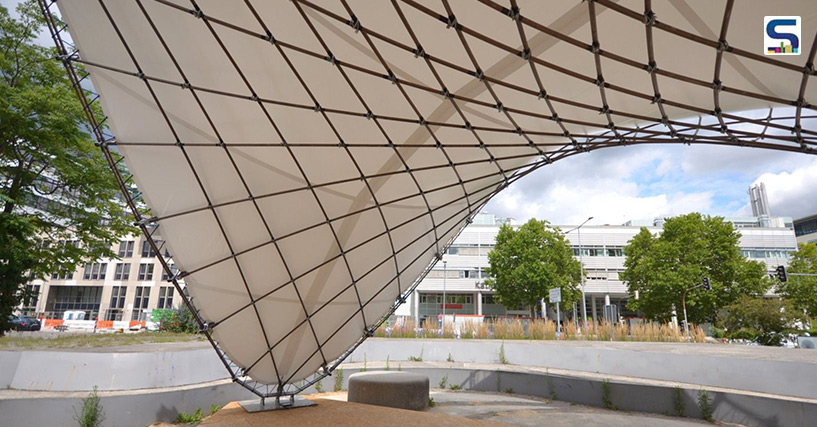

LightPRO Shell Pavilion, a 10 m span canopy, highlights bamboo-like qualities has been created under BioMat – architect Hanaa Dahy’s research area that advocates bio-based materials and material cycles in architecture. The profiles of the experimental pavilion, set up in the Stuttgart Stadtgarten, are biodegradable and can be used in a variety of structural applications or ephemeral structures. A report by SURFACES REPORTER (SR).

Unique doubly curved structure

A load-bearing shell structure has been combined in a bending active cross-beamed shell construction for the pavilion. It has been constructed under compression to form a unique doubly curved structure, which is combined with stretched membrane roofing under tension. Both these units are connected to double-profile beams that transform the forces from systems to the three footages connected to a superficial foundation.

Material- Natural Flax & Hemp Fiber

Bamboo-like pultruded profiles that are made of natural flax and hemp fibers have been used to create the bending active structure. The Pultrusion technique is a continuous process for manufacturing fibre-reinforced polymers with a constant cross-section. The fabricated natural fiber-based biocomposite profiles are freshly produced through pultrusion in the linked LeichtPro research project and are directly applied in this innovative structural application, presenting a sustainability approach in future architecture.

Similar to bamboo construction, the inner grid profiles have been attached through winded steel threads in a crossing format. However, the membrane is linked to the three footages, which are then stretched along the external beams through an extended rope to the compressed NFRP profiles similar to sailing ships.

Major Challenge

The active-bending systems are initially straight elements that are bent to form a curved shell. For this project, a number of design possibilities had been considered. The selected design was finally chosen depending on its distinctive shape. The challenge for the team was to make sure the material is sufficient to support the entire geometry that spreads across 44 profiles with lengths varying from 6 to 12.5 m. The pavilion spread across 10 m with 4.5 m in height at its highest point and 3 m near its head inner point.

Traditional diagonal lashing methods with steel cables join the profiles in a grid, where the grid is connected to the beam outline via a customized joint system. The membrane, however, is attached to the three foundations and is tensioned along the perimeter using rope lacing.

The aim was to create a product that matched the mechanical qualities of bamboo and other related materials. That said, the research is reportedly based on years of research in the field of the application of bio-based materials and various concepts for a future-oriented sustainable architecture.

Project details

Project: LightPRO Shell (BioMat Pavilion 2021)

Architect: BioMat

Location: Stuttgart University

BioMat director: Jun Prof Dr Ing M Eng Hanaa Dahy

BioMat team: Evgenia Spyridonos, Jan Petrs, Piotr Baszynski, Paulina Grabowska

Structural support: Yanan Guo, Marta Gil Perez

Geodesy team: Prof Dr Ing Volker Schwieger, Gabriel Kerekes

Membrane support: Bieri GmbH; Technical: Tomas Thommen

Membrane assembly: Zimmermann Zeltbauten; Technical: Ronald Burgau

Technical support: Michael Preisack, Michael Schneider, Michael Tondera

IntCDC laboratory: Sergej Klassen, Kai Stiefenhofer

Image credits: Green Product and Concept Award