Most of us by now might be aware of Ikea and how their DIY assembly kits took over the internet and the global furniture market and how their simplicity of designs appealed to a wide array of customers. Well, there has been a similar trend in architecture, any guesses??– it’s DIY! Now try and imagine building up your own college residence or weekend party cabin! How amazing would it be to be able to lounge about and the sense of accomplishment that you’d get from something that you built on your own?

Usually, DIY architectural designs wouldn’t require too much labour and technical expertise! They say “Truth is stranger than fiction” and this could certainly be the case here. There’s been a boom in the DIY movement and architecture is no stranger to it. Hence, SURFACES REPORTER (SR) took a dive into the DIY world to understand what makes it the choice of the youngsters and elders alike.

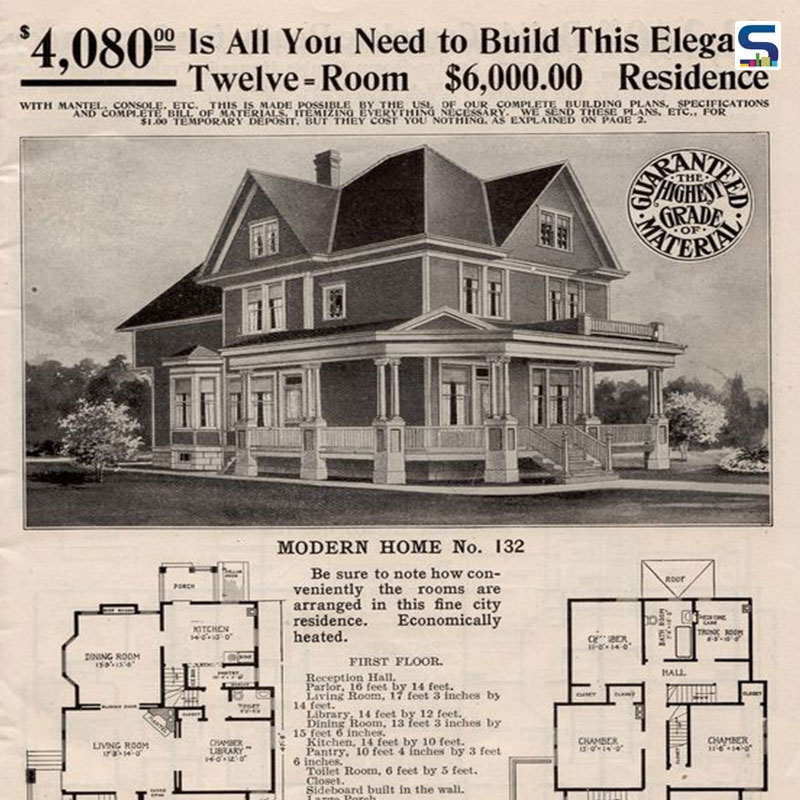

Halfway into the 20th century, a company by the name Sears, Roebuck and Co. sold tens of thousands of self-assembly homes to customers across the United States by mail order. A “Sears Modern Home” came in a railroad-delivered kit complete with more than 30,000 component parts, along with nails, paints, and fittings, and a heavy leather-bound instruction manual with all that you’d need to help you put together the designs yourself. The designs were simple enough to be assembled without any help from architects, carpenters, or any specialist contractors—in almost all cases, Sears homes were assembled solely by the buyer, with the help of friends, family, and neighbours, in a communal fashion.

These easy to understand and put together DIY structures are often flat-packed or come with a complete kit that helps you with the entire step-by-step process. Such a collection of DIY architecture and construction material showcases not only a bond between simplicity and economical pricing but this technique also helps do away with much construction waste and unnecessary materials involved in the process.

In the quest to find the perfect substitute for the mainstream concrete and wood many alternative materials like foamcrete, papercrete, and hempcrete were created. And wow we’ve even got something called aircrete – a foamy mixture of air bubbles and cement which is inexpensive to produce, DIY-friendly, and possesses the quintessential safeguarding properties required for construction.

Few Innovations in DIY Architecture:

The ideator of AirCrete, Hajjar Gibran wanted to create something that is a lightweight and low-cost building block which is fireproof, water-resistant, insect-proof, and serves to insulate the structure. You’ll be surprised to know that it reduces construction costs by up to 10 times and is quite easy to work with, especially for single-story homes.

Going on with the list, ever wanted to build a bamboo structure of your own? Well, say hello to the ‘Zome building kit’ by Giant Grass! This studio has made a DIY kit that is basically a dream LEGO project which can be housed in your backyard or be scaled up to create a large enough space to house a small community. The ‘zome’ can be described as a flexible space that can be used by children to hang out in the backyard, or a playful lounge for you to entertain guests in, a greenhouse for new saplings, a creative space in the office, a quiet space for home workouts, or a rigid tent – in easy words, it can be pretty much anything you want it to be. This is perfect for those who want to live sustainability and enjoy working on projects and comes with all accessories needed – precision-made bamboo strips, nuts, bolts, and an installation guide to make the perfect ‘zome’.

Setting up camp just got more fun and a whole lot easier thanks to Den! The cabin design studio has a range of flat-packed DIY-style kits that will let you assemble your very own A-frame cabin in just a matter of days. The average size for it is about 115-square-foot with models that can go a bit larger and smaller depending on your preference. Once assembled, it can be seen the slanted wooden walls and a floor-to-ceiling triangular window just like how we all thought of a cabin as children. The residing area is a bit on the minimal side and can be perfect for a cosy getaway, a small yoga studio, or a creative nest! The prefab pieces for the cabin are manufactured in New York and come with pre-drilled holes, all wooden structural parts that lock together, bolts even including the door hardware.

Thoughts for the Future

Though DIY architecture might seem like a thing of the hobbyists it certainly is making a mark even in the mainstream construction world and with the advantage of the flexibility and multiple options to choose from, we can say it with surety it is here to stay and grow.