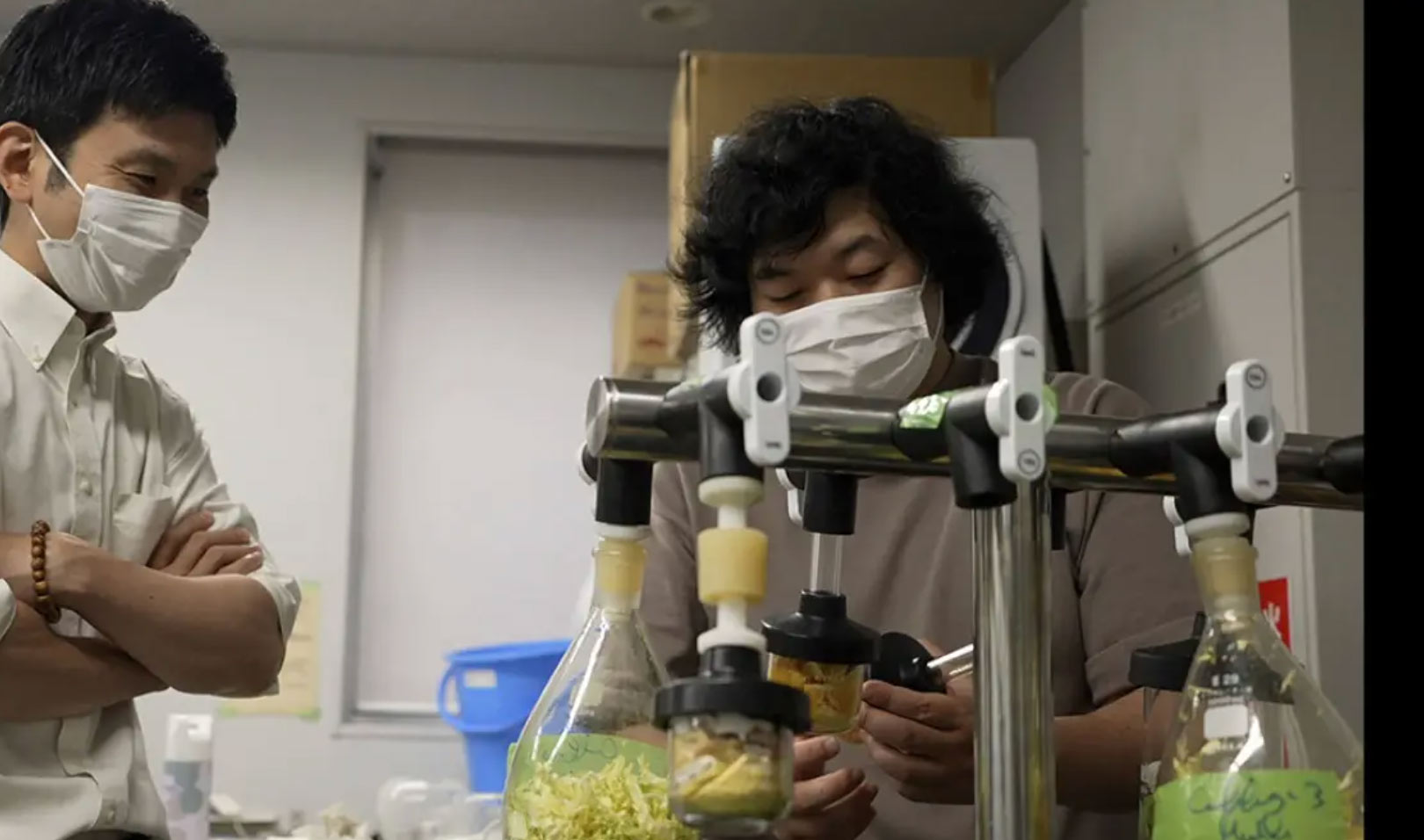

To combat food waste issues in Japan and worldwide, Two Japanese researchers Kota Machida and Yuya Sakai have come up with an innovative technology that can convert food waste into “cement” for construction purposes. According to them, it is the first process developed to create cement entirely out of food waste. The built material is said to be four times stronger than ordinary cement. SURFACES REPORTER (SR) brings more information about this edible cement. Take a look:

Also Read: Swedish Designer Converts Food Waste Into Versatile Furniture Pieces | Japan

Mitigate Global Warming

According to Sakai and Machida, this development will help lower global warming, eliminating problems related to food scraps that emit methane when they rot while buried in landfills.

Sakai, who is an associate professor of Industrial Science, innovated the technology while exploring eco-friendly materials that could substitute concrete. According to a study, cement production is responsible for 8 percent of the world’s CO2 gas emissions.

Sakai, who is an associate professor of Industrial Science, innovated the technology while exploring eco-friendly materials that could substitute concrete. According to a study, cement production is responsible for 8 percent of the world’s CO2 gas emissions.

How Edible Cement is Developed?

Researchers first developed to create concrete by pulverizing wood particles to heat compression. This undergoes a 3-step process of drying, pulverization, and compression, which can be done using simple mixers and compressors that one can buy on Amazon as per the researchers.

They employed similar techniques to create concrete out of food waste. In their previous experiments, they mixed plastics with the food to get the materials to stick together. But after months of failures, they found out that the cement could be fused by just adjusting the temperature and pressure used.

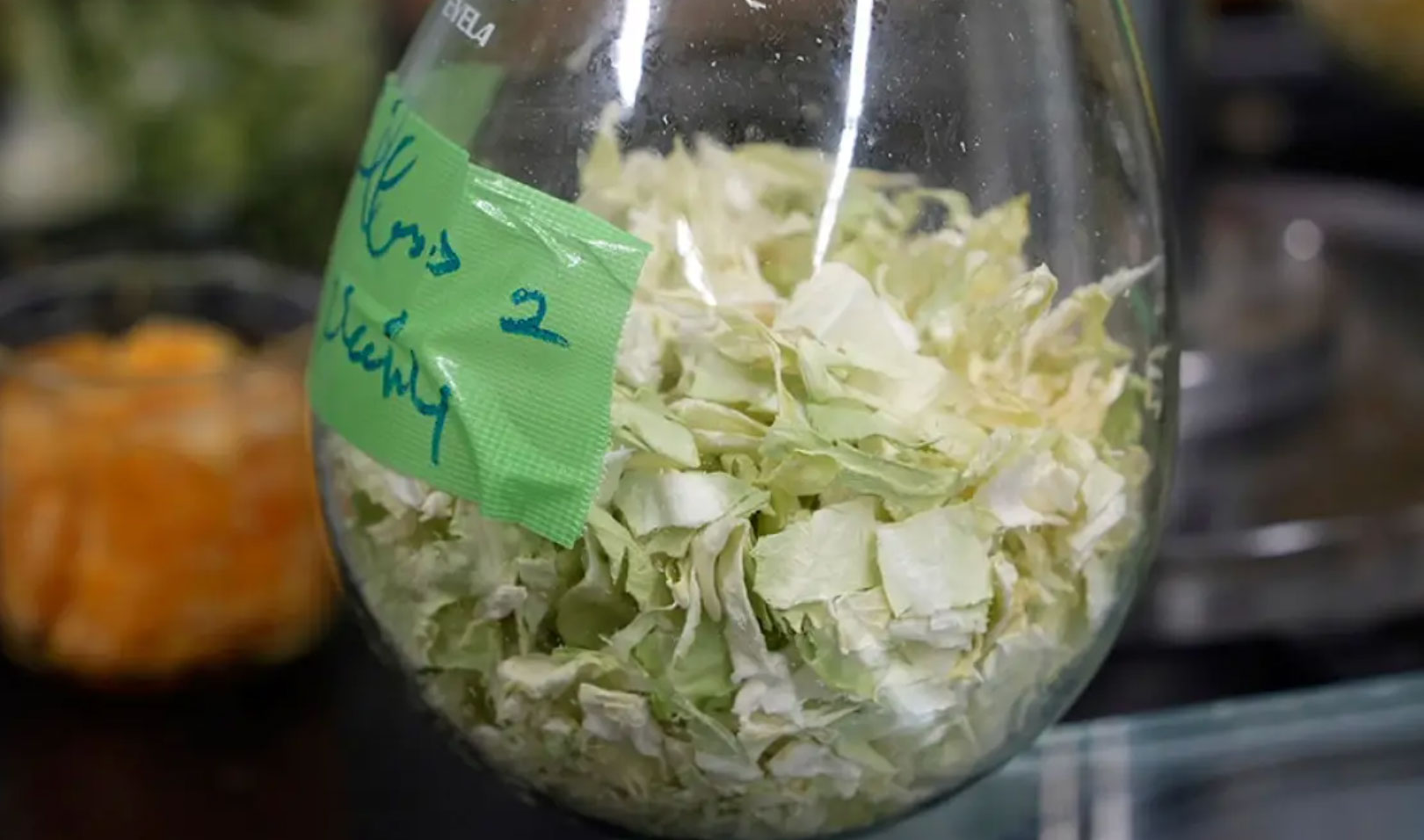

Sakai, with his student Machida, decided to do the same thing with food waste. Previous trials using food waste to make cement required plastics to be mixed in to get the materials to stick together. The researchers used Chinese cabbage, orange, tea leaves, onion peels, coffee grounds, and even lunchbox leftovers to create the cement.

Chinese cabbage being dried is seen in a glass flask at the laboratory of Tokyo University in Tokyo.

Chinese cabbage being dried is seen in a glass flask at the laboratory of Tokyo University in Tokyo.

The team adjusted the flavors with different spices which gave a scented, colourful and delightful appeal to the cement. To eat this material, one would need to break it into pieces and boil it, said Sakai.

Also Read: Fashion out of Ocean Food Waste

What Were The Challenges?

The major challenge was to adjust temperature and pressure levels as each type of food scrap have different temperatures and pressure levels.

So, earlier, they mainly used bio-waste ashes or coffee grounds as filler to create regular concrete. But later on, they successfully combined other materials such as tea leaves, Chinese cabbage, orange and onion peels, coffee grounds, and even lunchbox leftovers to create the cement.

So, earlier, they mainly used bio-waste ashes or coffee grounds as filler to create regular concrete. But later on, they successfully combined other materials such as tea leaves, Chinese cabbage, orange and onion peels, coffee grounds, and even lunchbox leftovers to create the cement.

Further, they might use Japanese lacquer to coat the cement to make it waterproof and protect it from being eaten by rodents or other pests.

Machida established a company called Fabula Inc. last year with two of his childhood friends. They have tied up with other companies to create cutlery, cups and furniture out of food cement. Sakai even notes that the process could be used in the future to make edible temporary housing in earthquake and disaster-prone areas.

Machida established a company called Fabula Inc. last year with two of his childhood friends. They have tied up with other companies to create cutlery, cups and furniture out of food cement. Sakai even notes that the process could be used in the future to make edible temporary housing in earthquake and disaster-prone areas.

“For example, if food cannot be delivered to evacuees, they could eat makeshift beds made out of food cement,” he said.

A biodegradable Product

As the food cement is made out of food scraps, it can be reused and is completely biodegradable. It can be buried when it is no longer required. The main goal of the team for developing this was to create cement that is sustainable and does not cause any harm to the environment.

Keep reading SURFACES REPORTER for more such articles and stories.

Join us in SOCIAL MEDIA to stay updated

SR FACEBOOK | SR LINKEDIN | SR INSTAGRAM | SR YOUTUBE

Further, Subscribe to our magazine | Sign Up for the FREE Surfaces Reporter Magazine Newsletter

Also, check out Surfaces Reporter’s encouraging, exciting and educational WEBINARS here.

You may also like to read about:

The Bricks Used To Create This Elephant Theater Are Made Out Of Animal Waste | Bangkok Project Studio

Student Designs Unique Furniture Out of Beer Waste | Beerterial

Designer Uses Coffee Waste to Design Homeware Products | SR Decor

And more…