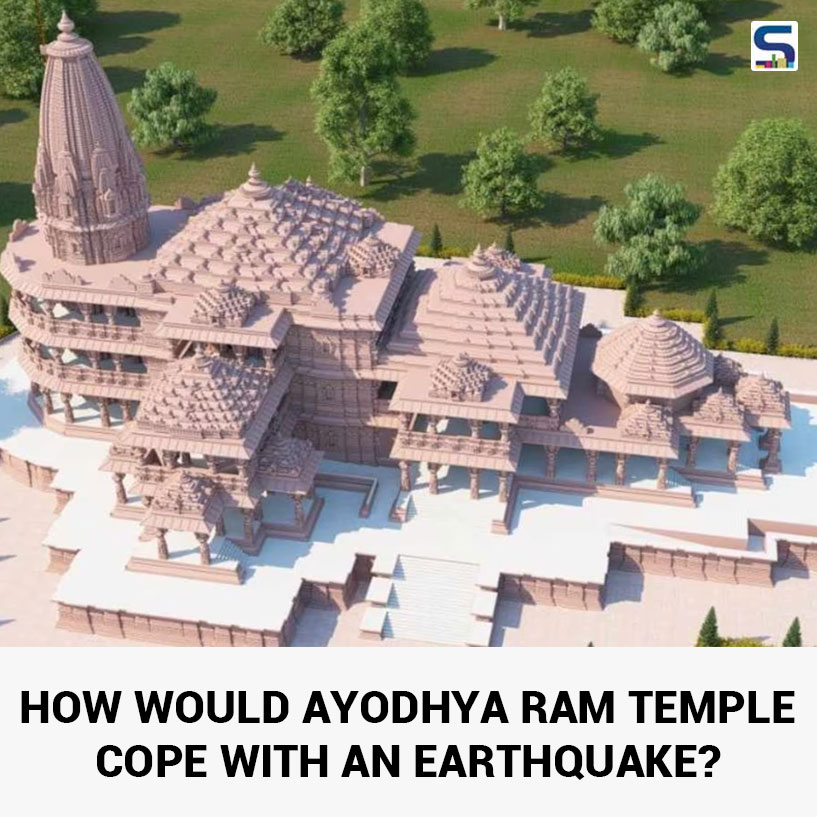

The Ram temple construction in Ayodhya is approaching its final stages, set for inauguration on January 22, with Prime Minister Narendra Modi leading the event. The temple, designed by Architect Chandrakant B. Sompura and constructed by Larsen and Toubro, with management by Tata Consulting Engineers Limited, is notable for its earthquake-resistant design, capable of enduring for 1,000 years without needing repairs. SURFACES REPORTER (SR) brings you a detailed report on how the temple is built to withstand climate vagaries.

Reflecting both North and South Indian temples, the project, interestingly, is built without using metal rods. To make it strong during earthquakes, they used stone instead of iron. They mainly used pink sandstone and carved marble from places like Mirzapur and Bansi-Paharpur in Rajasthan for the project.

Champat Rai, the general secretary of Sri Ram janmabhoomi Teerth Kshetra Trust, compares the temples foundation pillars to the sturdy supports of big bridges over strong rivers, ensuring the temples durability. Sh Girish Sahasrabhojanee, Design Construction Manager of the temple, explained that the temple is designed to last for 1,000 to 2,500 years without getting damaged.

No need of repairs for 1,000 years

The temples trustees say it wont need repairs for at least 1,000 years, even if theres a strong earthquake. This is because the foundation is 12 meters deep. In a notable revelation, the soil used for the foundation can solidify into stone within 28 days, with a total of 47 layers carefully laid during the construction process.

Champat Rai mentioned that a huge amount of granite, sandstone, and marble, including bricks donated in 1992, has been used in the construction.

The Director of CISR-Central Building Research Institute (CBRI) in Roorkee liked how they used stone in building the temple. Stone lasts longer than other materials, and they avoided using iron because it can rust. The whole temple, from the base to the top, is planned to use about 21 lakh cubic feet of stone.

Construction Materials

The materials employed in the construction of the Ayodhya Ram Mandir are of the highest quality, featuring "Rolled Compacted Concrete" without steel. The temple incorporates materials, including pink sandstone, granite stone, Shaligram rock, copper plates, gold, Ashtdhatu, and teakwood.

The foundation boasts a robust design, including a 14-meter thick rolled compacted concrete, 56 layers of compacted concrete made from fly ash/dust and chemicals, and a 21-foot thick plinth composed of granite.Remarkably, the temples construction stands out for its use of 17,000 granite stones, each weighing 2 tonnes.

The earthquake-resistant structure, spanning three stories, comprises 392 pillars, 44 gold-plated teakwood doors, and idols crafted from 60 million-year-old Shaligram rocks sourced from the Gandaki River in Nepal. Additionally, a 2100 kg bell made of Astadhatu, comprising gold, silver, copper, zinc, lead, tin, iron, and mercury, produces audible chimes reaching up to 15 km.

Unique Noon Reflection Mechanism

Nripendra Misra, who leads the Construction Committee, shared that the sculptors for the Ram Lalla statues were invited to Ayodhya. They brought special stones, like white Makrana marble and Karnatakas Krishna Shila, which were tested at the National Institute of Rock Mechanics.

Experts suggested a 7-foot height for each idol so that devotees can see them clearly from 25 feet away. A unique feature, designed by the Central Building Research Institute in Roorkee, directs sunlight onto the idols forehead at noon during Ram Navami.

In Ayodhya, the Ram Lalla Temple isnt just a place for prayers – its a strong and lasting symbol. Its special design, careful construction, and smart material choices mean itll stand tall for many, many years, becoming a timeless part of Indias amazing history and culture.