One of the most popular choices in the architecture and construction industry is that of timber in an attempt to reduce their embodied carbon emissions from other building materials such as steel and concrete. However, the sustainable potential of wood is limitedly known. Most of the uneven and offcut wood pieces with knots and forks which are waste products of the timber industry go unused or are turned into pellets and burned. Despite being exceptionally strong, forks in trees are often rejected in timber construction due to their crooked appearance. However, very recently a group of researchers at the Massachusetts Institute of Technology (MIT) have developed a way to use tree forks in construction projects not as cladding or finishes but as a structural element. Read SURFACES REPORTER’s (SR) complete report.

MIT researchers of the Digital Structures research group have developed an approach that would help architects to use discarded tree forks as load-bearing joints in their structures. A tree fork is a joint of a trunk or branch that splits into two, forming a Y shape piece. In architectural work, similar Y-shaped nodes are used where straight elements are joined. These nodes are stronger as they bear critical load.

With the help of digital and computational methods, tree forks can be made to be used as Y-shaped nodes that would connect straight building elements. Spread across five steps, this method has already been used to install a demonstration structure on the university's campus. According to Caitlin Mueller, Associate professor in the Building Technology programme at MIT and leader of the Digital Structures research group, “If you take a tree fork and slice it down the middle, you can witness an unbelievable network of fibres that are intertwining to create these often 3D load transfer points in a tree.” The team has adapted the same thing using 3D printing.

The team started by involving cataloguing a selection of tree forks into a digital library. This had been done with the help of 3D scanning and had been completed with a smartphone app. The scans captured the relative geometry and orientation of the branches, thereby determining the fork’s internal fibre orientation and its strength.

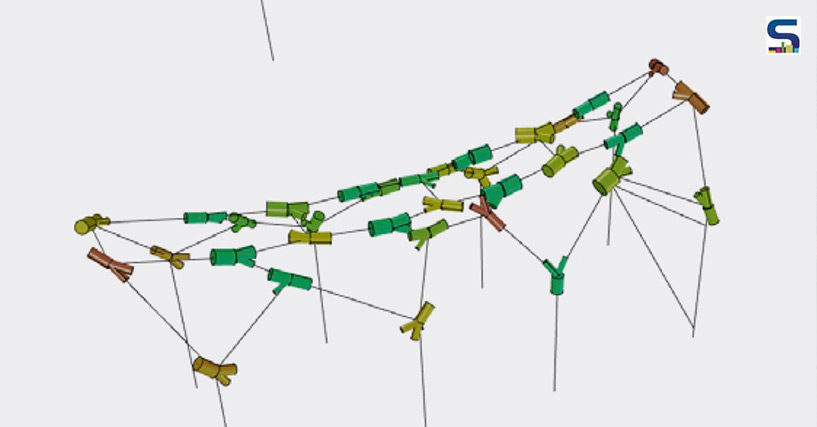

In the second step, the team matched the tree forks to the Y-shaped nodes in an architectural design. This was achieved through algorithms that showcased how well the shape of a particular tree fork could line up with a given node. To make the most efficient use of the inventory, it was necessary to adjust the overall distribution of tree forks. During the third step, the architects can play with the shape of the structure, given the algorithm is used for the matching process that would further recalculate the optimal tree fork distribution.

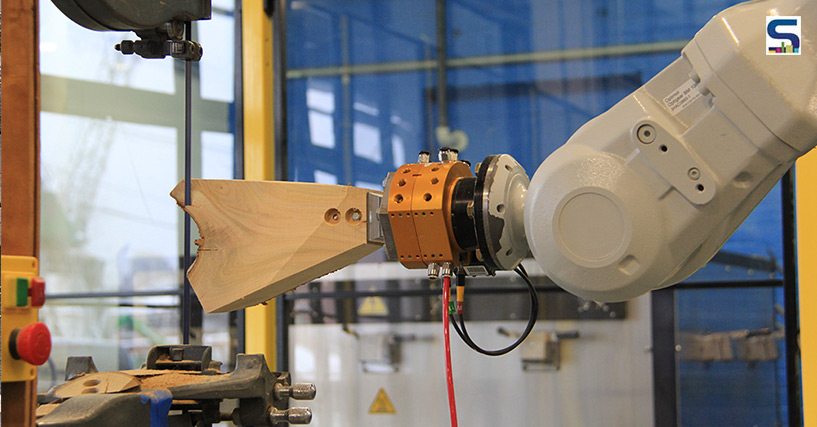

Upon finalizing the design, the cutting of the tree forks had been done minimum just to strip off the bark and make the joint fit the node. The fourth stage had been automated with an algorithm generating the code instructions. In the last step, the structure was manually put together with each tree fork that had been labelled to allow for straightforward assembly.

The team believes that this method could ultimately enable architects to explore new forms just like the computational design processes. The use of tree forks could reduce the environmental impact of construction by offering a replacement for high-strength materials such as steel which is consumed massively in the construction industry. Tree forks are natural and renewable. Additionally, they can be excessively sourced from the timber industry as a reclaimed waste product as the industry uses only the straight sections of the trees to design furniture and other building materials.

Image credits: Felix Amtsberg