Non-biodegradable and extremely harmful to our health and the environment, styrofoam is used for several purposes. However, it can now be transformed into materials for recycled plastic products by melting and treating it. However, these materials are often sent to other countries, which makes the entire process inefficient, wasteful, and still harmful to the environment in the long run.

For instance, Japan exports styrofoam melted into ingots only to have them turned into foundations for products bought in stores. To overcome this challenge, we+’s Refoam aims at starting and ending the issue in Japan right where styrofoam is melted. Know more about it on SURFACES REPORTER (SR).

A series of furniture pieces, Refoam is an attempt to reframe today's inappropriate and overly complex relationship between humans and materials. Part of we+'s research project, Urban Origin, the project aims at ‘using vernacular materials and treating them simply with our own hands,’ thereby exploring new values for styrofoam.

Waste styrofoam is collected in Tokyo. It is common to melt the material into ingots in intermediate treatment plants in Tokyo and its suburbs, and export most of it to Europe and South East Asia. The material in these countries is treated into granules and then into inexpensive recycled plastic products, mainly from China. However, in Japan, these products are typically sold in 100 yen shops. Despite higher recycling rates, the process remains very complex. Additionally, transportation between these countries is another problem. To overcome these challenges, Refoam explored the possibility of making ingots in intermediate treatment plants for manufacturing furniture.

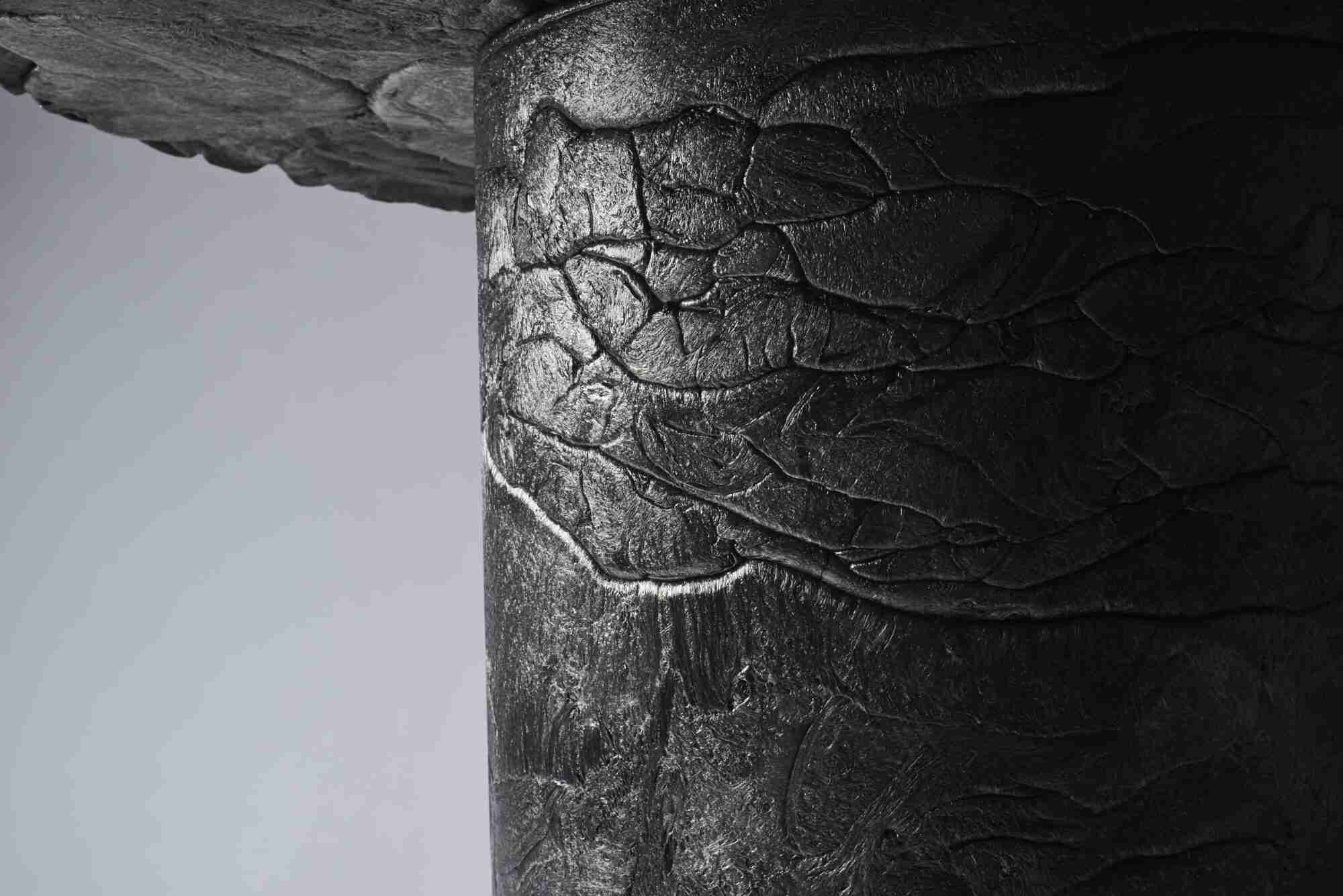

Refoam, thus, simplifies the recycling process and simultaneously adds a different value to styrofoam. The recycled material is used to build up structures that obtain unique textures. Each piece showcases a cracked concrete and molten lava texture upon cooling. The structures are transformed into tables, chairs and other furniture pieces that are suitable for indoor and outdoor use.

Image credits: Masayuki Hayashi