Dutch design studio Loop Loop has innovated a groundbreaking method of imbuing aluminium with colour through plant-based pigments, eschewing the use of petroleum-based alternatives. Odin Visser and Charles Gateau, founders of the Rotterdam-based studio, have pioneered what they call the world’s first plant-based aluminium dyeing process. According to the duo, this process entails the creation of four bio-based pigment solutions, which can be applied to aluminium via anodizing—a surface treatment technique commonly utilizing petroleum-derived pigments. Here is a detailed report on SURFACES REPORTER (SR).

Visser and Gateau cultivate their own plants for the pigments, reinforcing their dedication to localized production.

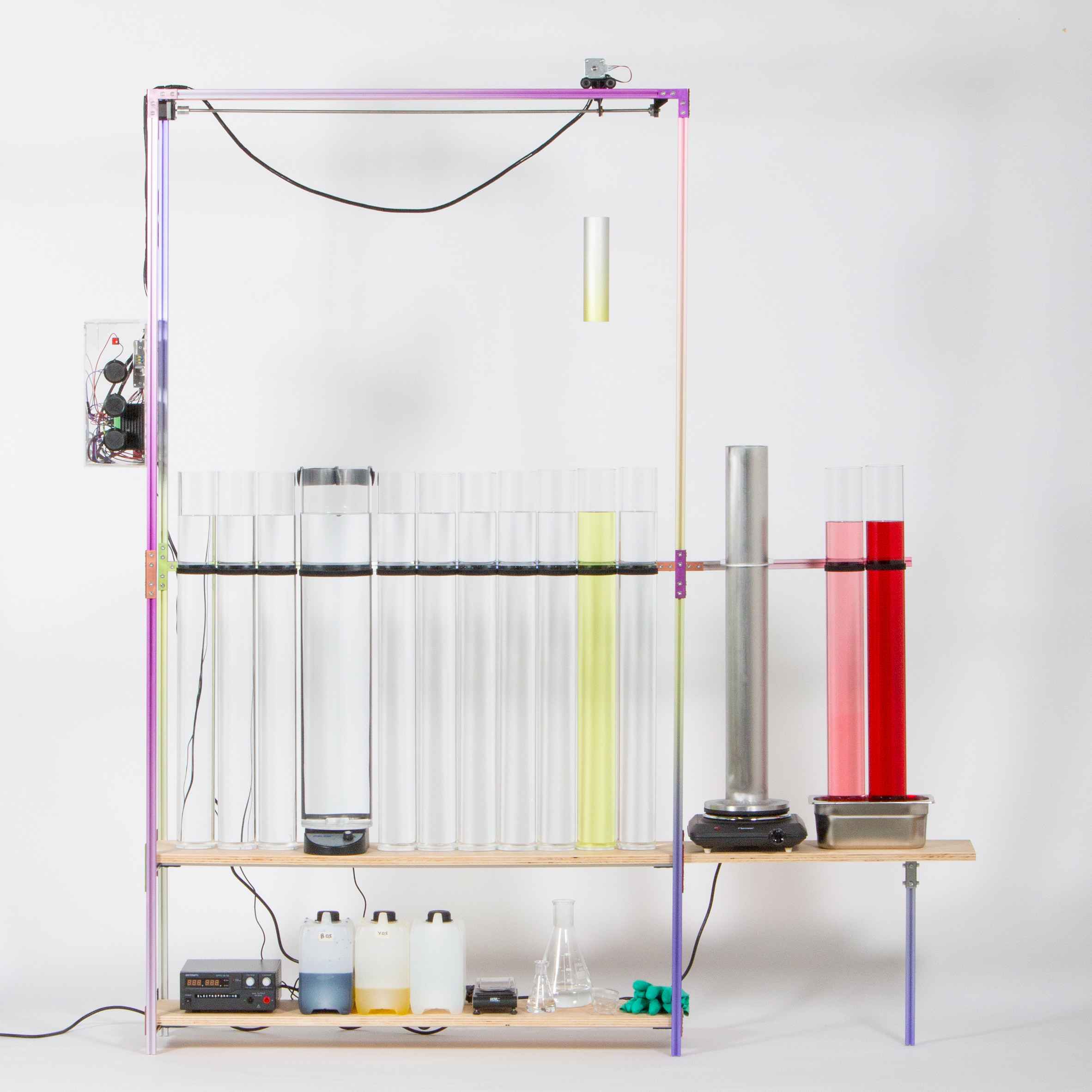

Visser and Gateau’s aspiration is to render the aluminium anodizing process more accessible to designers, artisans, and small-scale manufacturers, thus broadening its current predominantly mass production application. Their ultimate goal is to make their designs and formulas open source, enabling anyone to establish their production facilities. Their journey commenced with the introduction of the Magic Colour Machine during Milan Design Week 2022. This mobile, custom-designed machine enables the application of colour gradients to aluminium components from any location. Their latest venture, named Local Colours, delves into how this process can be rendered more sustainable.

The innovative process involves applying a thin aluminium oxide layer on the surface of the metal using an electric current.

Loop Loop has developed four dyes so far, including warm purple from dyer’s alkanet flowers, mustard yellow from dyer’s rocket flowers, deep pink from madder root, and bright gold from red onion. These pigments are applied to metal using varied techniques, resulting in an array of effects, including smooth gradients and textured finishes.

The innovative process involves applying a thin aluminium oxide layer on the surface of the metal using an electric current. The studio’s tests indicate that plant-based anodizing finishes behave similarly to petroleum-based ones, except for colour reactions under direct sunlight due to the intricate and diverse molecular structure of natural-based dyes.

Loop Loop has developed four dyes so far, including warm purple from dyer’s alkanet flowers, mustard yellow from dyer’s rocket flowers, deep pink from madder root, and bright gold from red onion.

Visser and Gateau cultivate their own plants for the pigments, reinforcing their dedication to localized production. Their intention is to foster a community of designers, researchers and makers sharing insights and results in the realm of circular products and service systems once the recipes become open source. They are aiming to launch this platform in 2024.

Image credit: Loop Loop