At Expo 2025 Osaka, a striking architectural installation titled the Blue Ocean Dome Pavilion has been constructed by Japanese architect Shigeru Ban, in collaboration with designer Kenya Hara. Commissioned by the Zero Emissions Research and Initiatives (ZERI), this pavilion is positioned just beyond The Grand Ring and stands out not only for its innovative design but also for its commitment to sustainability and environmental education. The pavilion is composed of three interconnected domes, namely, Dome A, Dome B and Dome C, each employing different materials and structural philosophies that reflect Ban’s architectural ethos and ingenuity. Know more about the Blue Ocean Dome Pavilion on SURFACES REPORTER (SR) as it serves as an architectural and educational beacon within Expo 2025 Osaka.

The exhibits, curated and designed by Kenya Hara, are located in Domes A and B.

Lightweight Architecture

The design of the Blue Ocean Dome places strong emphasis on sustainability, minimal environmental impact and ease of disassembly after the Expo. The use of lightweight construction materials ensures that the structures can be efficiently dismantled and repurposed, reducing post-event waste. Each dome features a polycarbonate skin, unifying the trio visually while supporting their independent structural systems.

Constructed from carbon-fibre reinforced plastic tubes, a material more commonly associated with aerospace and automotive engineering.

Dome A, the entrance structure, is made from laminated bamboo. This choice stems from Japan’s strict building regulations, which do not permit the use of untreated or natural bamboo as a structural material. To meet compliance, Ban opted for laminated bamboo, which allows control over strength, quality and durability. This engineered bamboo enables innovative structural applications that would otherwise be prohibited using natural forms. This solution also highlights the balance between traditional materials and modern regulations, allowing natural resources to be reimagined through technology.

Dome C, the exit structure, is built from cardboard tubes, a signature element in Ban’s body of work.

Sustainable Trio

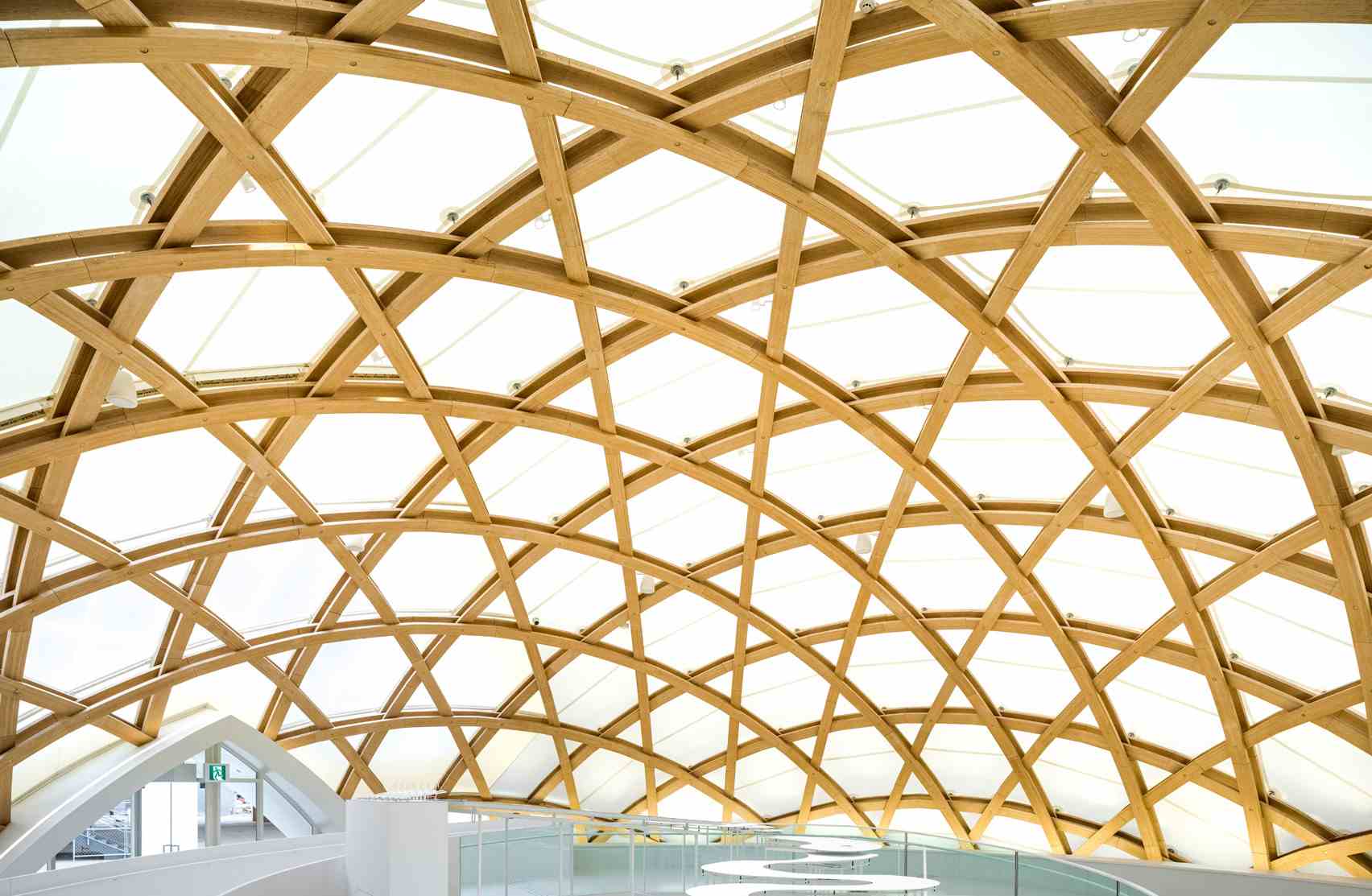

In contrast, Dome C, the exit structure, is built from cardboard tubes, a signature element in Ban’s body of work. Known for his pioneering use of cardboard in disaster-relief architecture and temporary installations, Ban brings this lightweight, recyclable material into an Expo setting, forming a molecular-like geometric pattern. This material choice reinforces the project’s low-impact philosophy while maintaining structural coherence with the rest of the pavilion.

Dome A, the entrance structure, is made from laminated bamboo.

The largest of the trio, Dome B, stands as the centerpiece of the installation. Constructed from carbon-fibre reinforced plastic tubes, a material more commonly associated with aerospace and automotive engineering, it demonstrates Ban’s willingness to explore unconventional resources in architecture. He selected carbon fibre specifically because of its lightweight yet durable properties, which allowed for the entire structure to be built without the use of concrete piles. According to Ban, the weight of the structure is less than the soil displaced during foundation preparation, thereby eliminating the need for deep foundations. This not only reduces environmental disruption but also shortens the construction timeline, which is an important factor for temporary event structures. One of the highlights is a 360-degree film projection in Dome B, which envelops visitors in a cinematic narrative about ocean conservation, combining visual impact with educational purpose.

One of the highlights is a 360-degree film projection in Dome B, which envelops visitors in a cinematic narrative about ocean conservation, combining visual impact with educational purpose.

Inside the Blue Ocean Dome, the focus shifts to content and experience. The pavilion hosts immersive exhibits that raise awareness about the value and fragility of the world’s oceans, particularly in the face of pollution caused by human activity. The exhibits, curated and designed by Kenya Hara, are located in Domes A and B.

Image credit: Hiroyuki Hirai