Amazon recently unveiled a groundbreaking warehouse made primarily of mass timber in Elkhart, Indiana, USA. Touted as a testbed for more than 40 sustainability strategies aimed at shaping the future of its global building operations, the facility is designed by ZGF Architects. The new warehouse, called DII5, represents a significant step in Amazon’s journey toward achieving net-zero operations by 2040, offering a practical framework to evaluate and scale sustainable design and construction practices across its portfolio. SURFACES REPORTER (SR) shows how Amazon’s evolving commitment to integrating low-carbon materials, renewable energy technologies, and ecological design is all infused in its one facility.

The primary structure utilizes Southern Yellow Pine cross-laminated timber (CLT) panels and glulam beams.

A green warehouse

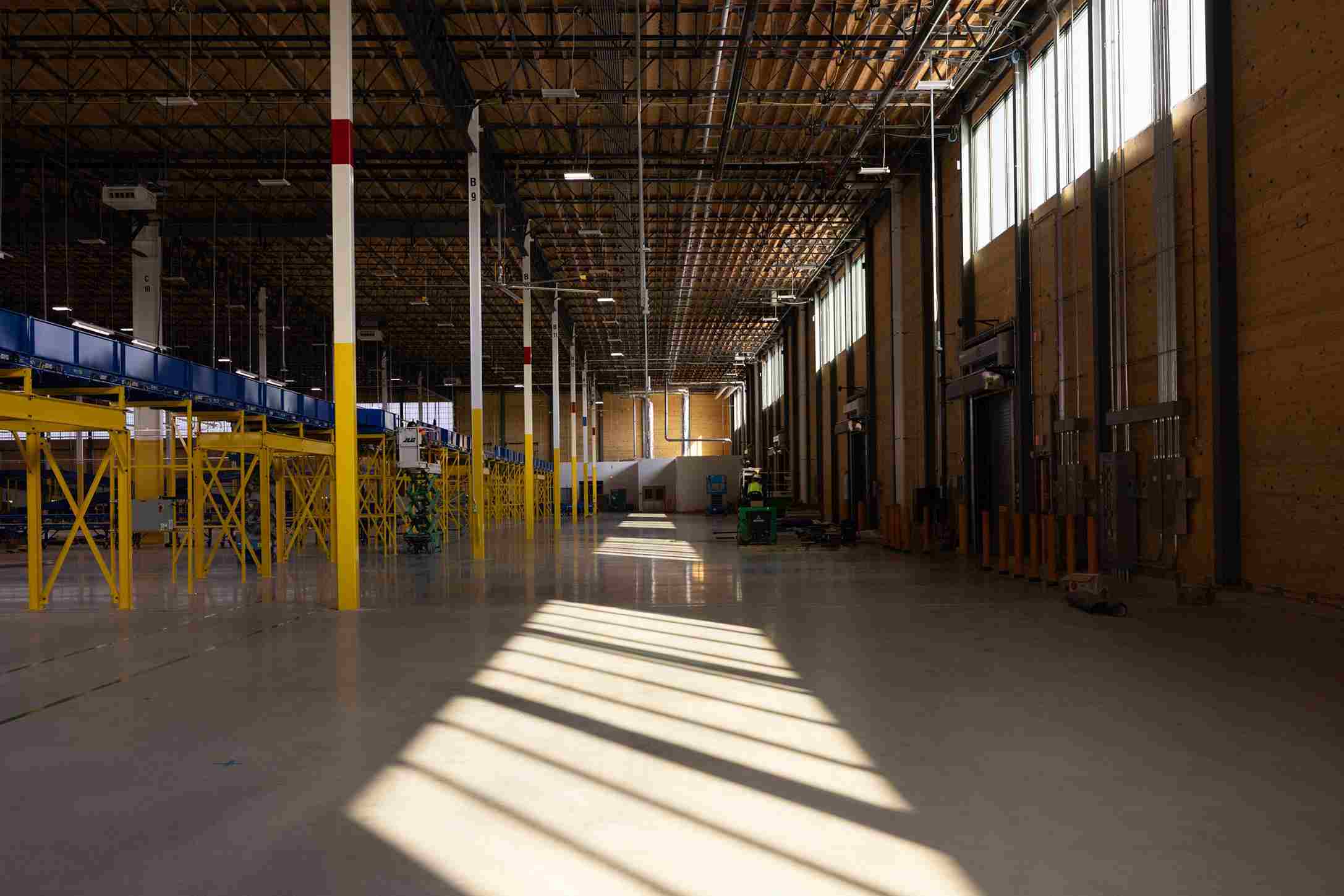

The DII5 facility stands out as the first large-scale, owner-occupied mass timber logistics building in the United States, a milestone that underscores Amazon’s intent to reduce the environmental impact of industrial construction. The design integrates a wide range of sustainable features, from energy-efficient lighting and electric vehicle (EV) charging stations to natural daylighting and advanced stormwater management systems. According to Amazon, the project goes beyond meeting internal sustainability goals and is also meant to serve as a test and learn platform for both Amazon and the wider construction industry.

The design integrates a wide range of sustainable features, from energy-efficient lighting and electric vehicle (EV) charging stations to natural daylighting and advanced stormwater management systems.

The warehouse’s design prioritizes natural materials and climate-responsive construction. The primary structure utilizes Southern Yellow Pine cross-laminated timber (CLT) panels and glulam beams. The materials are chosen for their strength, durability and significantly lower embodied carbon compared to conventional steel or concrete. The walls are insulated with wood fibre insulation, further enhancing the building’s thermal performance. Clerestory windows line the expansive delivery floor, allowing ample daylight to flood the interior, thus reducing the reliance on artificial lighting. Amazon reportedly notes that the circadian lighting system adjusts throughout the day to align with natural light cycles, improving employee well-being and energy efficiency.

The company also intends to analyze how the building performs under varying weather conditions to assess resilience and durability.

Over 40 sustainable innovations

The project site integrates several nature-based and low-impact design strategies. Permeable paving reduces surface runoff, while a bio-retention pond captures and filters stormwater on-site. The use of lower-carbon concrete in certain structural components also reflects Amazon’s experimentation with alternative materials that can cut down embodied emissions. In line with these efforts, the DII5 facility is targeting Living Future’s Zero Carbon Certification, which is a globally recognized benchmark for buildings that fully offset or eliminate carbon emissions through their life cycle.

Clerestory windows line the expansive delivery floor, allowing ample daylight to flood the interior, thus reducing the reliance on artificial lighting.

Reports suggest, Amazon plans to rigorously monitor the building’s performance over time, evaluating parameters such as total embodied carbon, operational energy efficiency, water conservation and biodiversity impact. The company also intends to analyze how the building performs under varying weather conditions to assess resilience and durability. Insights from this testing process will inform future Amazon projects and help refine sustainable design standards across different climate zones and facility types.

The use of lower-carbon concrete in certain structural components also reflects Amazon’s experimentation with alternative materials that can cut down embodied emissions.

The initiative builds upon Amazon’s broader experimentation with mass timber construction in other locations, including its HQ2 campus in Arlington, Virginia, and several international facilities in Australia and the UK, many of which have already achieved the Zero Carbon Certification. The Elkhart warehouse, however, marks a new phase in the company’s sustainability roadmap by combining multiple strategies within a single facility.

Image credit: Amazon and Kendall McCaugherty