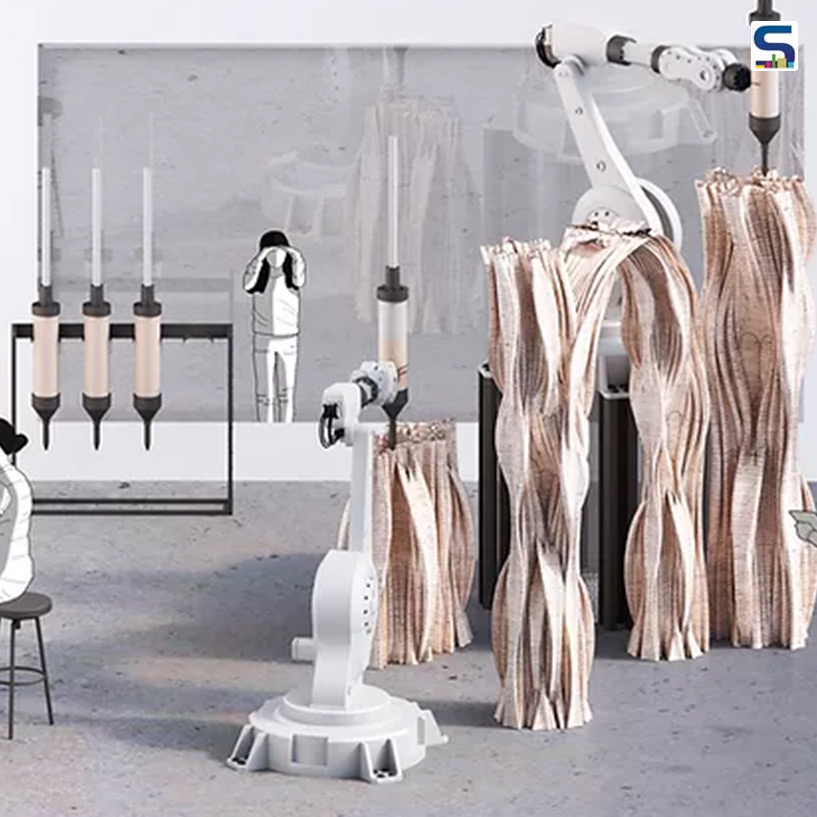

A new method of 3D printing with mycelium – the vegetative root of fungi – has been developed by London-based Blast Studio. Also known as shiro, mycelium is an underground network of fungal threads or hyphae, which the studio has used to 3D print a living architectural column called Tree Column.

Its name has been derived from its rigid and wavy structure which is reminiscent of tree trunks. Standing over 2 m high, its biomass structure has been algorithmically designed to provide strength and the necessary growing conditions for mycelium.

The idea was to create a multi-purpose structure that can be harvested for mushrooms while also serving as a functional building column that can self-repair.

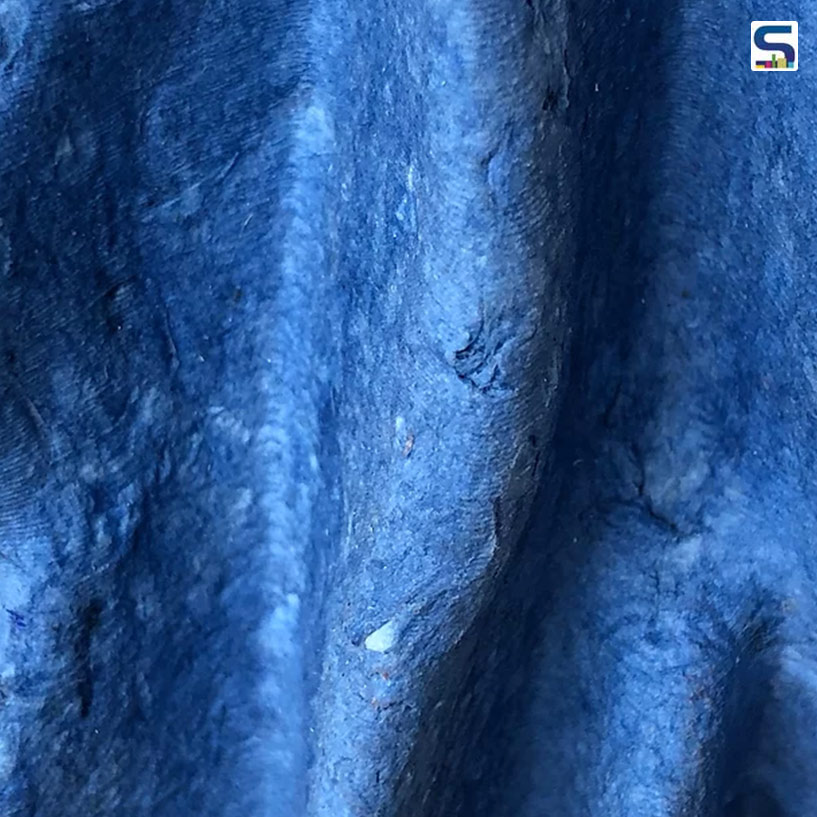

The production process starts with the shredding of waste coffee cups that are collected from around London. They are boiled in water to produce a sterilized paper pulp, which is then mixed with mycelium along with desired natural pigments to add colour.

The biomass paste is fed into a custom-made cold extruder similar to the kind used for 3D printing with clay where layers are 3D printed to form 10 separate modules that are stacked into a column measuring 2.1 m high and fused together using more mycelium.

Upon printing into shape, mycelium consumes the pulped paper cups and starts to grow to take over the whole column, thereby producing mushrooms that can be picked off and eaten. The mycelium root structure is further dried to create a load-bearing architectural element with natural insulating and fire-retardant properties.

For the initial three to four weeks until the mycelium has grown to encompass the entire column, the structure needs to be kept inside as it needs a humid environment away from any airflow. Furthermore, it is dried at 80o Celcius to kill the organisms to curb its growth and solidify the material.

Blast Studio confirms that the structure bears a similar capacity to MDF. The column is light and good in compression and flexion due to the elasticity of the material. It can, therefore, be used in small constructions such as houses and small buildings where concrete could be easily substituted by mycelium. In addition, if the column gets damaged or is no longer required, it can be recycled or reprinted.

Blast Studio is in plans to create a self-repairing version of the column by drying the mycelium to an extent it stops propagation without killing the organisms that would allow it to re-grow once exposed to water. That said, the studio has also developed a range of tables, lights and interior cladding options.

Image credits: Blast Studio