A method of 3D printing with seed-impregnated soil which can be used to create walls and roofs heaving with plants has been recently invented by a group of researchers at the University of Virginia (UVA). Here is a detailed report on SURFACES REPORTER (SR).

The researchers built the prototypes that looked like ordinary raw earth structures.

The researchers built the prototypes that looked like ordinary raw earth structures.

The researchers built prototypes that looked like ordinary raw earth structures. However, over a few days, they started to sprout and cover in greenery, thereby leading the UVA to compare them to oversized Chia Pets. As per the UVA, building elements such as green walls and roofs could be constructed using this method, thereby bringing the benefits of natural insulation, food prevention and green spaces for animals, pollinators and people.

Building elements such as green walls and roofs could be constructed using this method, thereby bringing the benefits of natural insulation, food prevention and green spaces.

Building elements such as green walls and roofs could be constructed using this method, thereby bringing the benefits of natural insulation, food prevention and green spaces.

The blending of soil and seeds into 3D printable soil inks could potentially lead to green architectural features woven into their fabric rather than just layered on top. Additionally, it also has the potential to cut back on carbon by opting for a circular alternative, which according to the researchers can be reused again and again. The team is currently working with local soils and plants mixed with water. Electricity has been used only to move the material and run a pump during the printing. However, if printing is not needed or if it isn’t the right quality, it can be recycled and reused in the next batch of inks.

The blending of soil and seeds into 3D printable soil inks could potentially lead to green architectural features woven into their fabric rather than just layered on top.

The blending of soil and seeds into 3D printable soil inks could potentially lead to green architectural features woven into their fabric rather than just layered on top.

The team also informs that buildings made with this technique have the potential to be carbon neutral as the plants covering can draw down carbon dioxide from the atmosphere. The researchers have aimed at creating an active ecological system that could store carbon in 3D printed soul structures through the process of photosynthesis.

In the beginning, the team used this method to create a small series of self-supporting structures resembling beehives. Published in the journal Additive Manufacturing, the aim of the team had been to create structures that would be solid enough to stand by themselves and also provide enough moisture and nutrients to support the germination process and growth. For this, the team opted for stonecrop, which is a succulent plant that can grow and survive with little water, as the extrusion process makes the soil compact and dry.

The team also informs that buildings made with this technique have the potential to be carbon neutral as the plants covering can draw down carbon dioxide from the atmosphere.

The team also informs that buildings made with this technique have the potential to be carbon neutral as the plants covering can draw down carbon dioxide from the atmosphere.

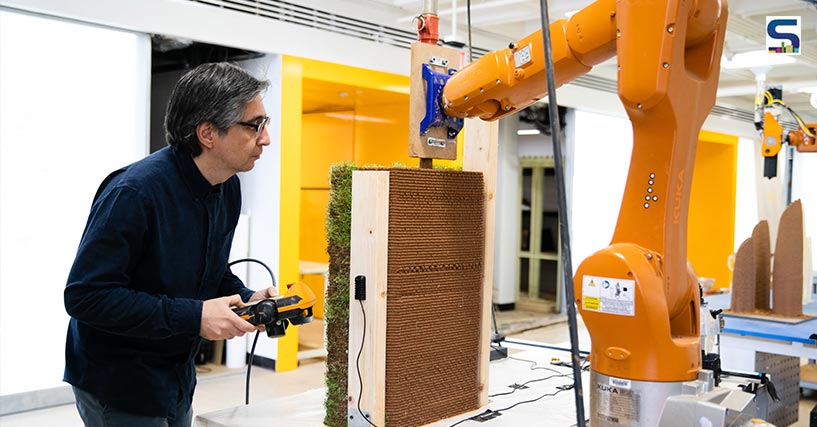

Since then, the team started printing larger objects including low walls which are about a metre in height. The team is now in plans to mount the 3D printing system on a moving robot to allow the production of taller, complex structures with multiple sides. They further also plan to experiment with using multiple material layers within a wall panel to allow the dry inner wall to be insulated from the moist outer wall.

Image credits: Ehsan Baharlou