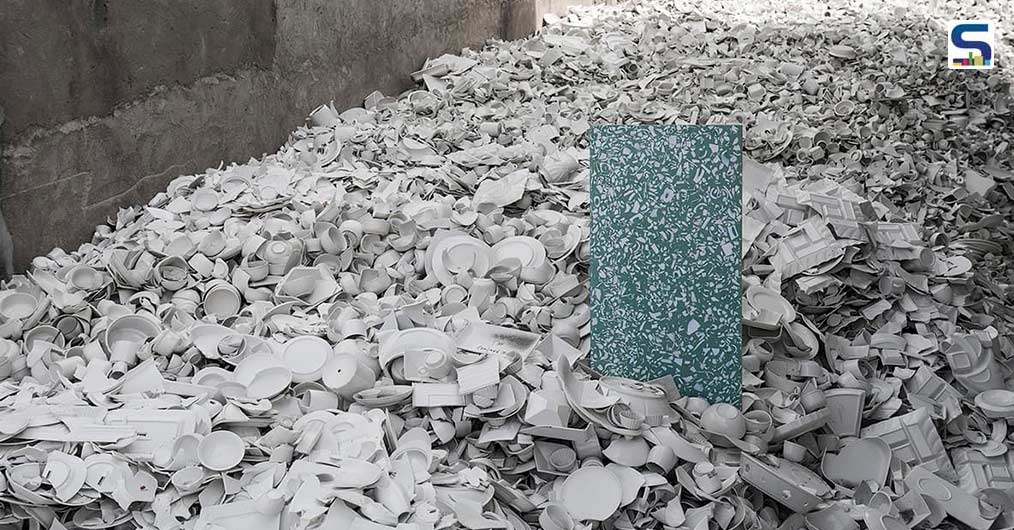

The rapid development of the ceramic industry in the eastern Guangdong province of China led to an increase in the amount of ceramic waste in Chaozhou – which is known to supply nearly 70 per cent of the total daily-use ceramic commodity for the world. Making it the world’s largest daily-use ceramics production base, Chaozhou is left with heaps of wasted ceramics. A recycling plant in the city recovers 1,000 ton of waste ceramics per year. This is not only across the ceramics industry in Chaozhou but also the aftereffect of uneven global economic development. “This is the garbage of China as well as the world. Sustainable development is not only an environmental issue but also an approach to a comprehensive understanding and decision-making, consisting of security, durability, practicality and economic feasibility, environmental compatibility and social responsibility,” cites Gang Xu, Founder, Guangzhou Bentu Culture and Development.

Bentu is known for transforming wasted daily-use ceramics, which cannot be degraded and re-used are smashed, for reuse.

Bentu is known for transforming wasted daily-use ceramics, which cannot be degraded and re-used are smashed, for reuse.

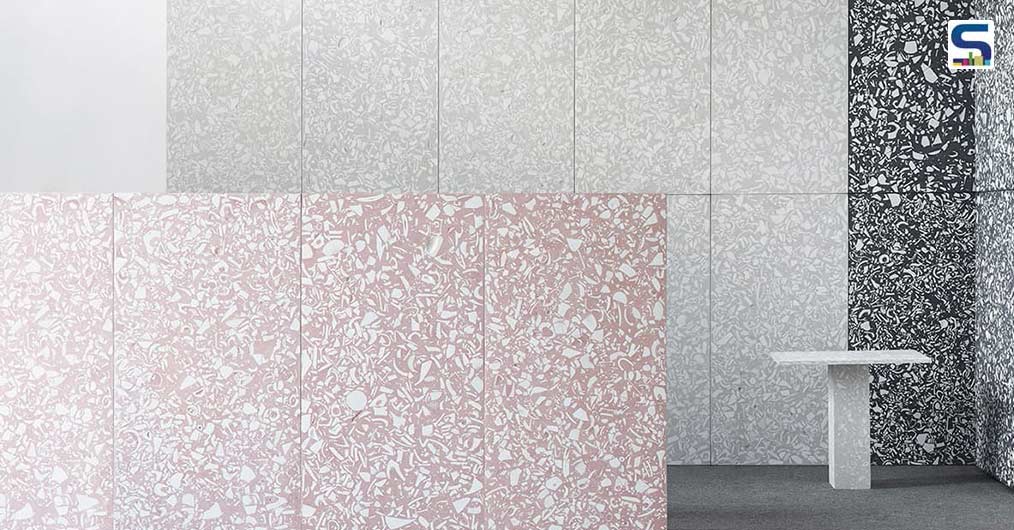

The independent design brand Bentu is known for transforming wasted daily-use ceramics, which cannot be degraded and re-used are smashed, for reuse. Its Spike Collection of decorative bricks is one way to explore this possibility. Starting from the availability of resources, technical and economic feasibility, and environmental compatibility, the design studio uses recycled daily waste ceramics as aggregate and high-performance concrete as cement, where the pattern is ground and polished after curing. The recycled daily-use waste porcelain is then mixed with the formulated high-performance concrete for mass production. “We mix the recycled wasted daily-use ceramics of about 40 per cent with the high-performance concrete prepared and carry out mass production. With the surface ground and polished, the product is very expressive,” adds Xu.

The design studio uses recycled daily waste ceramics as aggregate and high-performance concrete as cement.

The design studio uses recycled daily waste ceramics as aggregate and high-performance concrete as cement.

Features

Initially, the design studio collected ceramic waste from local roadsides and refuse collection points in Chaozhou. The stunning texture of the decorative tile is available in shades of black, grey, white, green, blue, yellow, red and brown. Available in dimensions of 1200 mm X 600 mm and 2400 mm X 1200 mm, these tiles are ideal for mainly wall decoration as well as flooring.

The recycled daily-use waste porcelain is then mixed with the formulated high-performance concrete for mass production.

The recycled daily-use waste porcelain is then mixed with the formulated high-performance concrete for mass production.

The studio offers two types of aggregate matching styles: the first is composed of eight colours where the waste porcelain is scattered at random and full of tension and is suitable for wall use; while the other is composed of four colours and the discarded daily-use porcelain is more finely smashed and classified and then reused.

The design studio collected ceramic waste from local roadsides and refuse collection points in Chaozhou.

The design studio collected ceramic waste from local roadsides and refuse collection points in Chaozhou.

Future of waste ceramic

For the studio, ‘local is the world and there are no barriers to creation.’ The goal of the studio is to make sure the proportion of large and small ceramic particles are distributed in a well-proportioned, meticulous and compact manner with better antifouling performance that is more suitable for ground use and can also meet the matching needs of various spaces.

Available in dimensions of 1200 mm X 600 mm and 2400 mm X 1200 mm, these tiles are ideal for mainly wall decoration as well as flooring.

Available in dimensions of 1200 mm X 600 mm and 2400 mm X 1200 mm, these tiles are ideal for mainly wall decoration as well as flooring.

As for the studio’s plan ahead, Xu tells us, “We will continue to use this material in our products, making lamps, furniture, etc to make more of these non-biodegradable materials sustainable.”

Product details

Material: Concrete, construction recycled slag aggregate

Dimensions: 298 mm X 298 mm X 28 mm

Weight: 3 kg

Image credits: Bentu