EcoLogicStudio, a design practice, has successfully converted algae into a biodegradable biopolymer, which has been utilized to create a 3D-printed tree sculpture capable of performing photosynthesis. Known as Tree One, this impressive self-supporting sculpture stands 10m tall and was showcased at two exhibitions hosted by Hyundai in Korea—Habitat One in Busan and Habitat One: Sustainable Shelter in Seoul. Here is a detailed report on SURFACES REPORTER (SR).

Known as Tree One, this impressive self-supporting sculpture stands 10m tall.

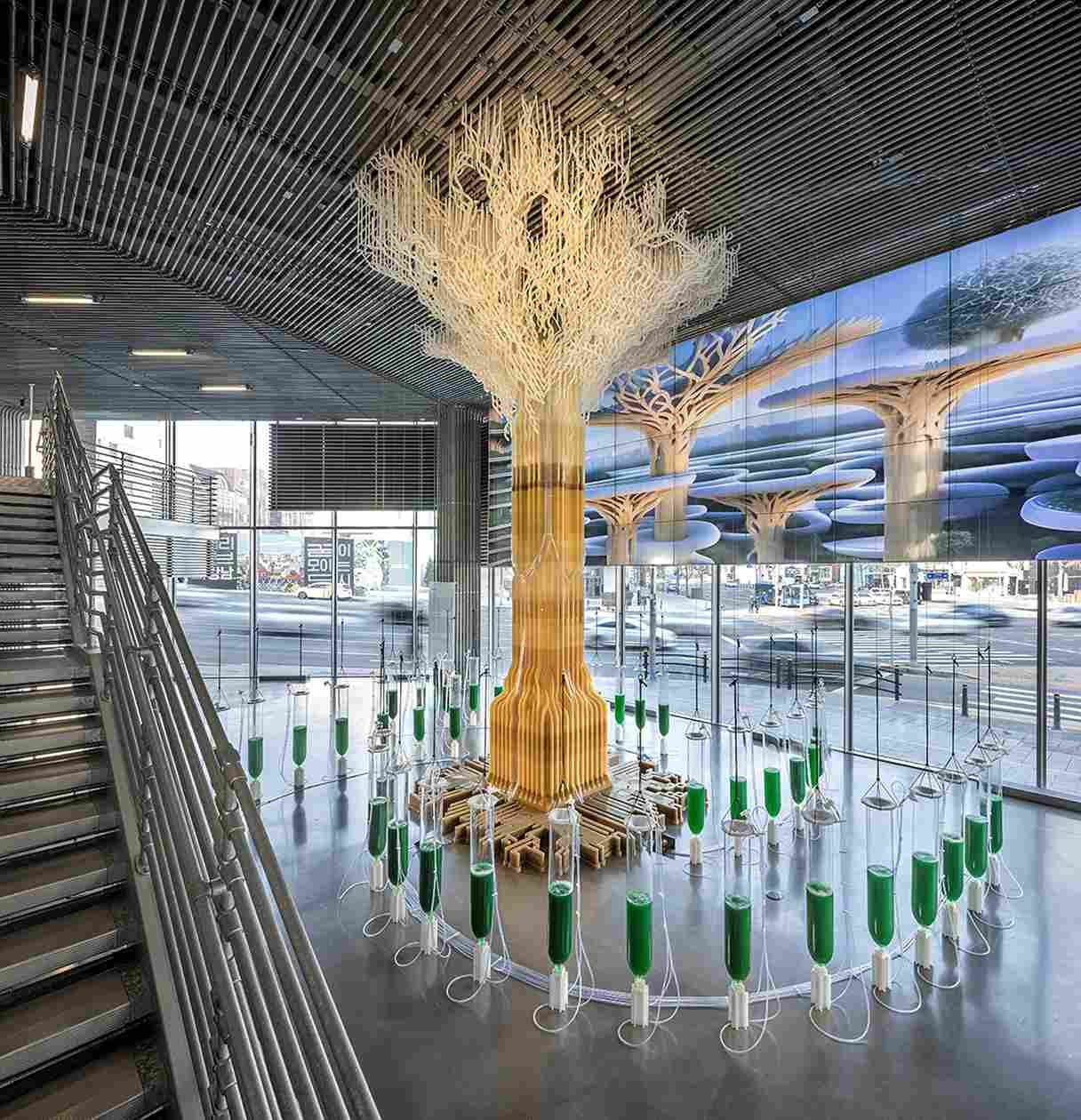

Tree One incorporates two elements derived from algae. Firstly, the trunk is 3D-printed using a biopolymer developed by EcoLogicStudio from harvested microalgae biomass. Secondly, numerous photobioreactors are integrated into the trunk and base of the installation, housing living cyanidium microalgae cultures. The recent installation in Seoul incorporated 40 glass photobioreactors containing 500l of algae cultures, actively engaging in photosynthesis to remove carbon dioxide from the air and release oxygen. According to EcoLogicStudio, this installation had a photosynthetic potential equivalent to that of 12 mature trees.

The trunk is 3D-printed using a biopolymer developed by EcoLogicStudio from harvested microalgae biomass.

EcoLogicStudio has long been fascinated by the air-purifying capabilities of algae. Unlike mechanical filters that merely extract pollutants, microalgae actively consume and grow by feeding on pollutants, thus producing biomass. The harvested biomass primarily consists of microalgae, also known as phytoplankton, a single-celled organism. When microalgae is cultivated in artificial environments like EcoLogicStudio’s photobioreactors, it needs to be harvested every few weeks to make way for new growth and remove decayed cells. The harvested biomass offers several possibilities for EcoLogicStudio—it can be reused in new photobioreactors or dried out and transformed into materials or even food sources.

The recent installation in Seoul incorporated 40 glass photobioreactors containing 500l of algae cultures, actively engaging in photosynthesis to remove carbon dioxide from the air and release oxygen.

For Tree One, EcoLogicStudio experimented with synthesizing a completely biodegradable biopolymer capable of 3D printing. Despite its softness, the biopolymer gains structural stability through its morphology, providing a material suitable for architectural applications. By converting biomass into a material, EcoLogicStudio effectively stores the captured carbon until it biodegrades, similar to timber. To create the biopolymer, EcoLogicStudio combined the biomass with four other biodegradable ingredients: chitin (derived from mycelium, mushrooms, or crustacean shells), agar (derived from potato peel or corn), vinegar and glycerin.

According to EcoLogicStudio, this installation had a photosynthetic potential equivalent to that of 12 mature trees.

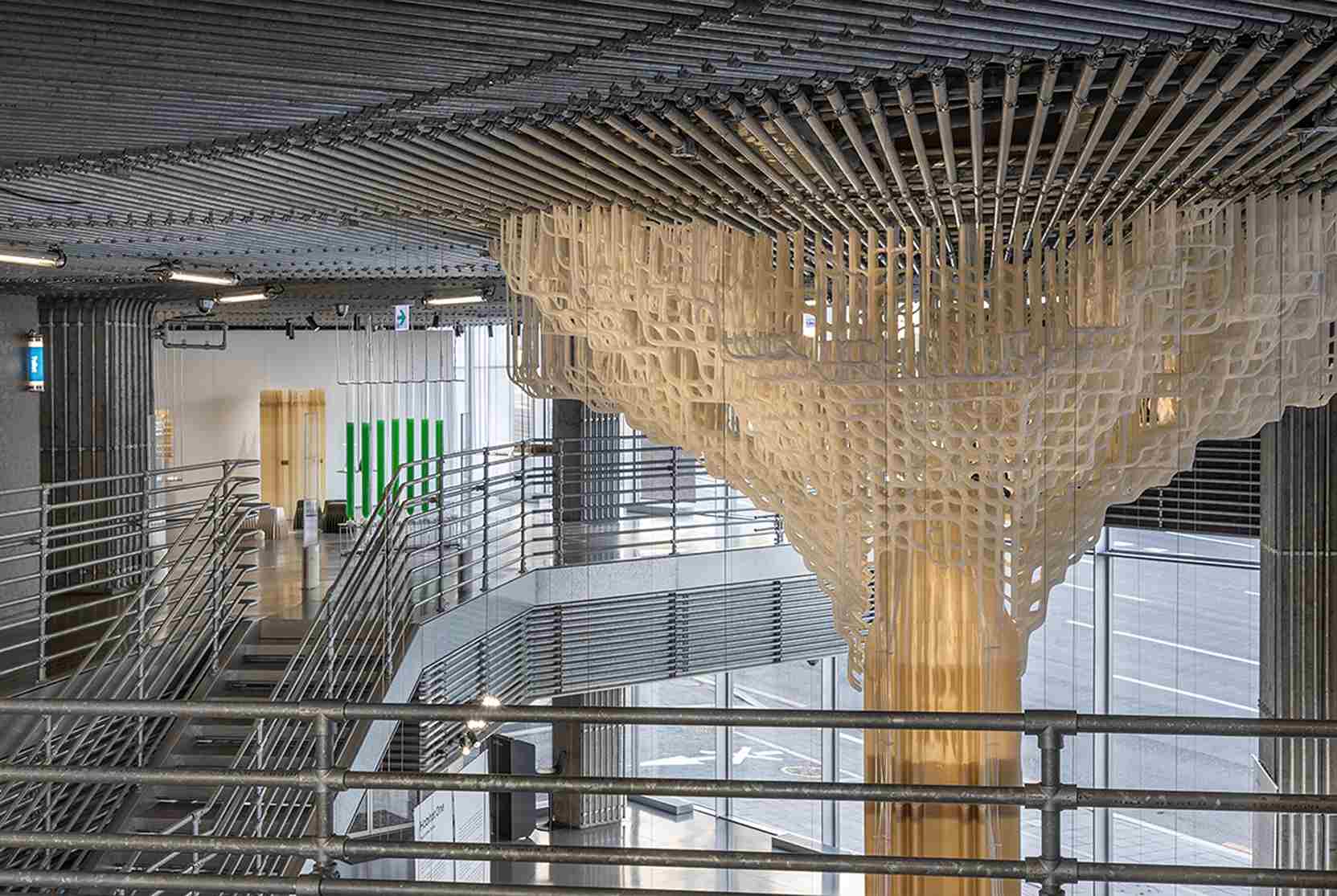

Four industrial robots and 20 large-scale 3D printing machines were utilized to extrude this material and form the pleated structure of Tree One, which mimics the fibrous trunks of real trees and provides strength. The design process incorporated algorithms inspired by architectural columns and arboreal systems, simulating the biological intelligence of nature to maximize strength using pliable material. Starting with a minimal path algorithm, the designers simulated how fibers would grow from the base of a tree to the top. Another algorithm transformed the fiber bundles into solid folds that could be extruded with a continuous line. Tree One, with its innovative use of algae-based biopolymer, is already suitable for cladding interiors or exteriors, while further experimentation on larger self-supporting structures continues.

Photographs: Joonhwan Yoon; Courtesy: EcoLogicStudio