A team of researchers from the University of Michigan has developed a biodegradable formwork using sawdust to address wood waste in concrete laying processes. This innovative material is an outcome of the BioMatters project led by the Digital Architecture Research and Technologies (DART) Lab at Taubman College of Architecture and Urban Planning. Know more about it on SURFACES REPORTER (SR).

This innovative material is an outcome of the BioMatters project led by the Digital Architecture Research and Technologies (DART) Lab at Taubman College of Architecture and Urban Planning.

Under the leadership of DART director Mania Aghaei Meibodi, along with researchers Muhammad Dayyem Khan, Tharanesh Varadharajan and Zachary Keller, the team aimed to repurpose industrial sawdust to minimize waste from formwork used in concrete construction. By combining sawdust with biopolymers and additives, the team developed a versatile material suitable for molding or 3D printing into various shapes.

The team aimed to repurpose industrial sawdust to minimize waste from formwork used in concrete construction.

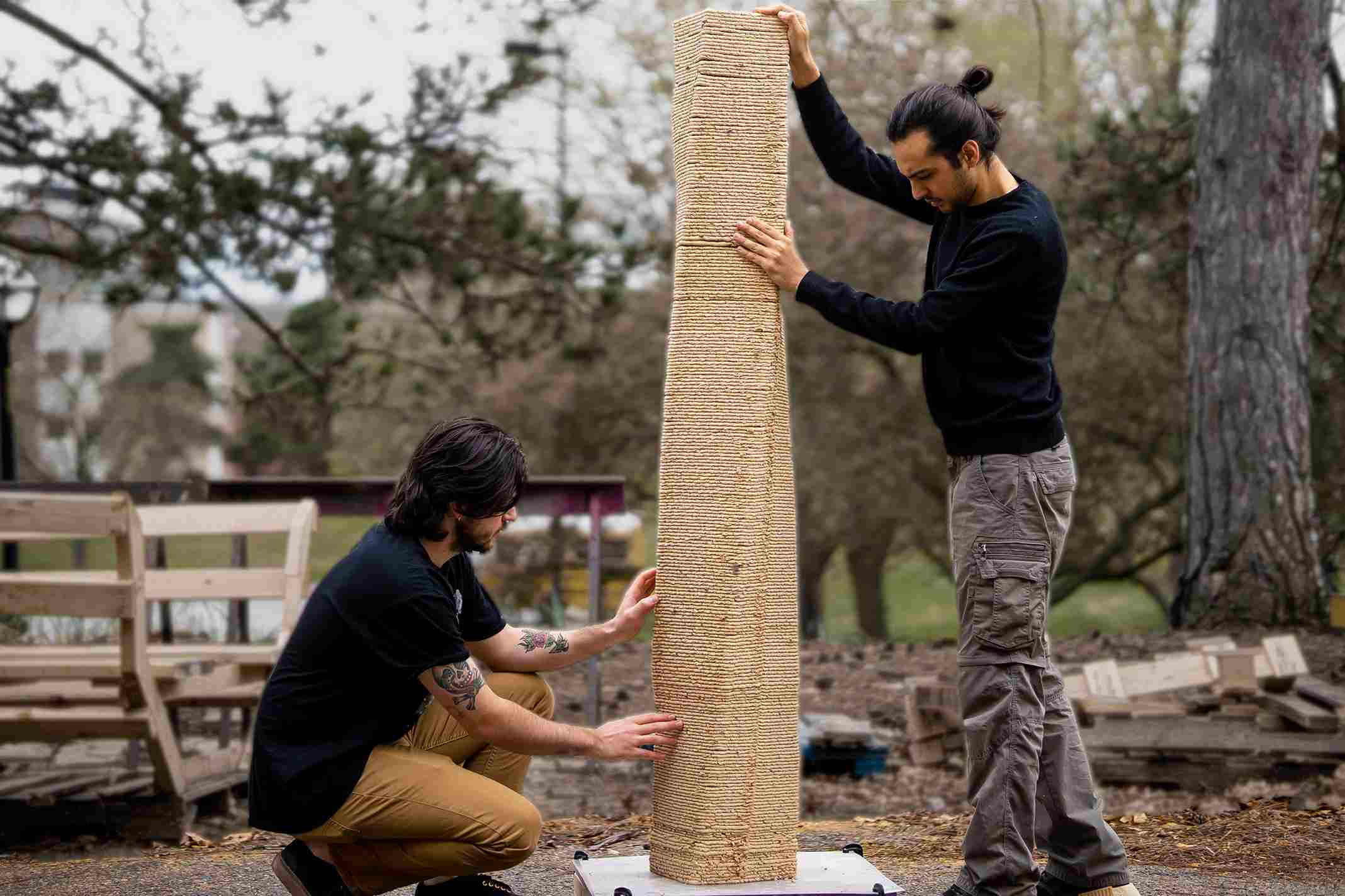

Demonstrating its capabilities, they utilized this material to create concrete formwork. The team 3D-printed a structural column, gradually filling its core with concrete. After drying, the sawdust formwork was removed, unveiling the column. To be sustainable, the sawdust material was saved and recycled by reestablishing the required viscosity level for 3D printing. This enabled the team to reuse the same material more than 25 times to produce additional columns.

The team 3D-printed a structural column, gradually filling its core with concrete.

Given the staggering global statistic of 15 billion trees being felled annually, resulting in vast amounts of sawdust discarded in landfills or burned, causing environmental concerns, the project holds significant environmental promise. Formwork constitutes a substantial portion of concrete construction costs (up to 40 per cent), traditionally constructed from wood and often discarded after use on construction sites. The team plans to further explore the potential of this material, including its application beyond concrete construction and experimentation with various types of wood.

Image credit: DART Lab